The nice thing about the classic scooters is the very simple technology.

It doesn't matter whether it's the engine, the electrical system or the controls. Everything is kept very simple and efficient.

But even with the simplest assemblies, a lot has happened in the last few decades. While the first Vespa models used simple, bare steel bowden, which had to be subjected to constant maintenance with grease and oil, modern trains are now fitted with a so-called liner. The liner is a small tube made of a very slippery material that is located in the outer shell and makes constant maintenance of the cables practically unnecessary. Have this effect in one blog explained.

The new liner of the bgm Pro Silk Liner trains offers a very low resistance for the inner cable even under high stress and thus the lowest actuating forces.

The crux of the matter with old, worn or bad cable pulls is that the more force is required to move a component via the cable pull, the greater the force that is required to overcome the resulting friction of the cable alone.

As a small theoretical example, operating a clutch with an old cable.

Actuation of the clutch requires a pulling force of 10 kg directly on the clutch arm on the clutch cover.

However, if you pull the cable at the top of the handlebars that actuates this clutch arm, the force required here is significantly greater than directly on the clutch arm.

Why?

On the way up into the handlebars, the cable has to describe a few radii, so it has to go around the curves in the frame and steering head. These radii are where the inner cable rubs more against the outer shell. This friction is multiplied by the sum of radii on the way up to the lever. This means that at the top of the lever you no longer need 10kg but 12kg of traction to overcome the friction of the cable.

Now we equip the clutch from our example with stronger springs. This means that a pulling force of 15kg is required directly below on the clutch arm in order to actuate the clutch. However, the pulling force required at the top of the lever is no longer 17kg but 25kg. Because the friction within the cable pull increases drastically due to the higher load on the clutch arm.

This is where modern materials intervene to reduce this friction under high loads.

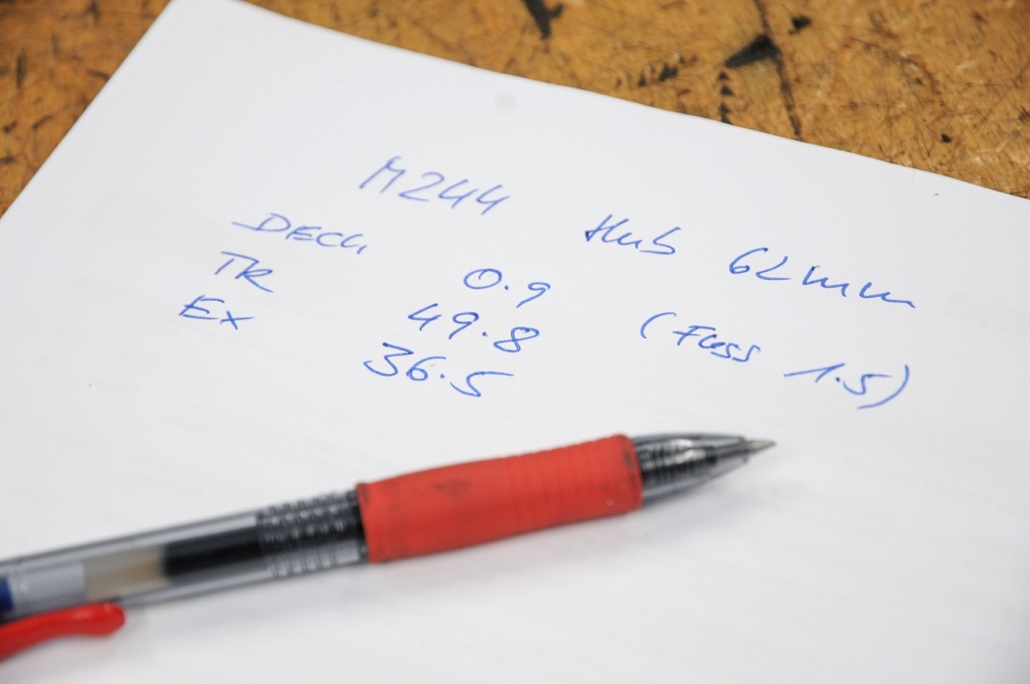

I did a little test for you to find out how much power each type of cable pull consumes.

To ensure that the test leads to a meaningful result, all tested trains always have the same length and are intended for the same application on the vehicle. So that the effect of the increased friction can be tested in the difference, I have greatly exaggerated this area. This means that each cable was always wrapped around a round body with 2,5 windings. So many more radii, i.e. friction points, are generated here than is possible in a vehicle. This exaggeration only serves to get the results clearer.

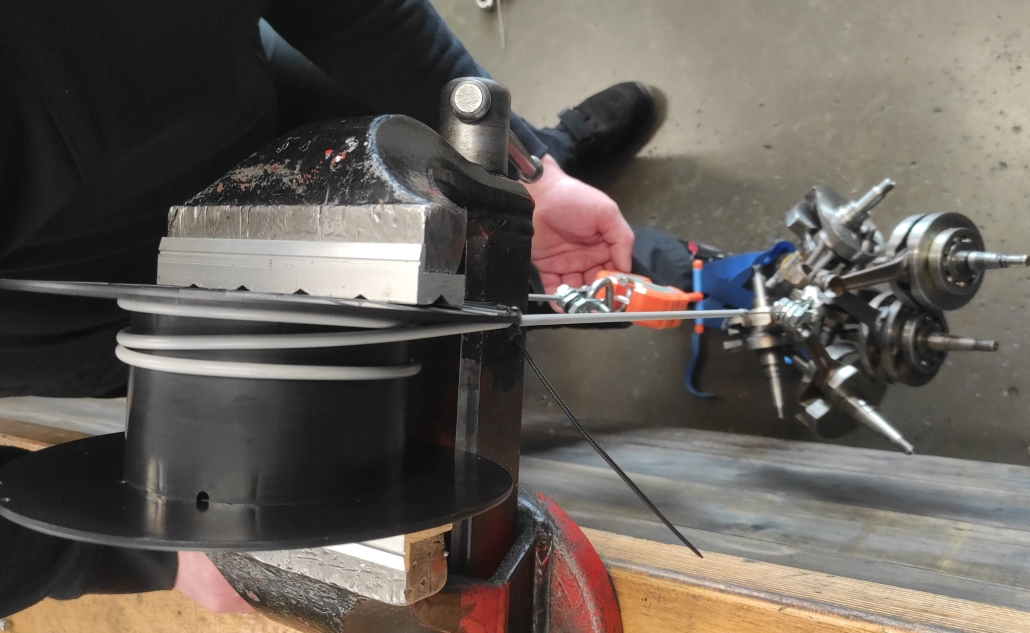

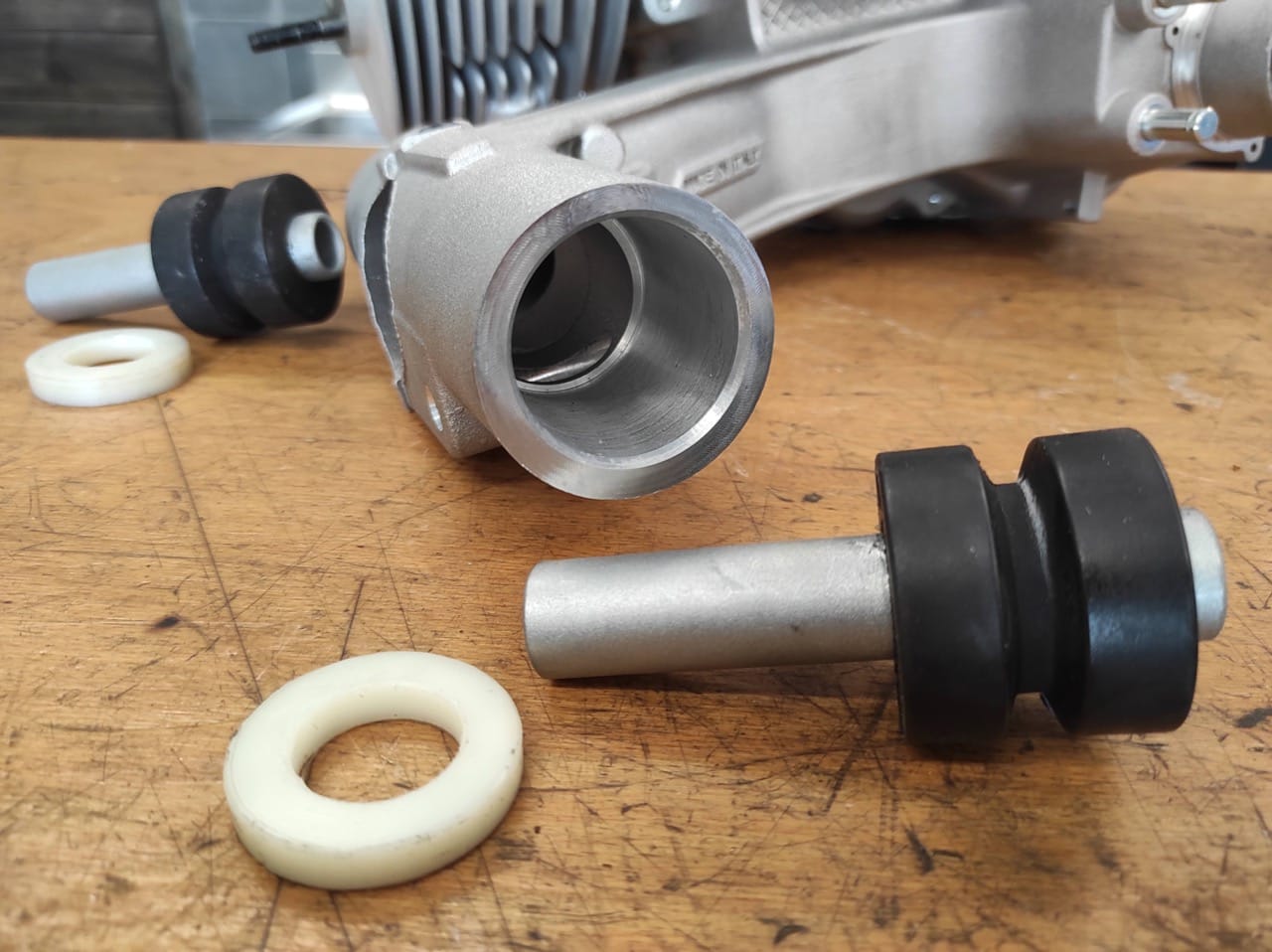

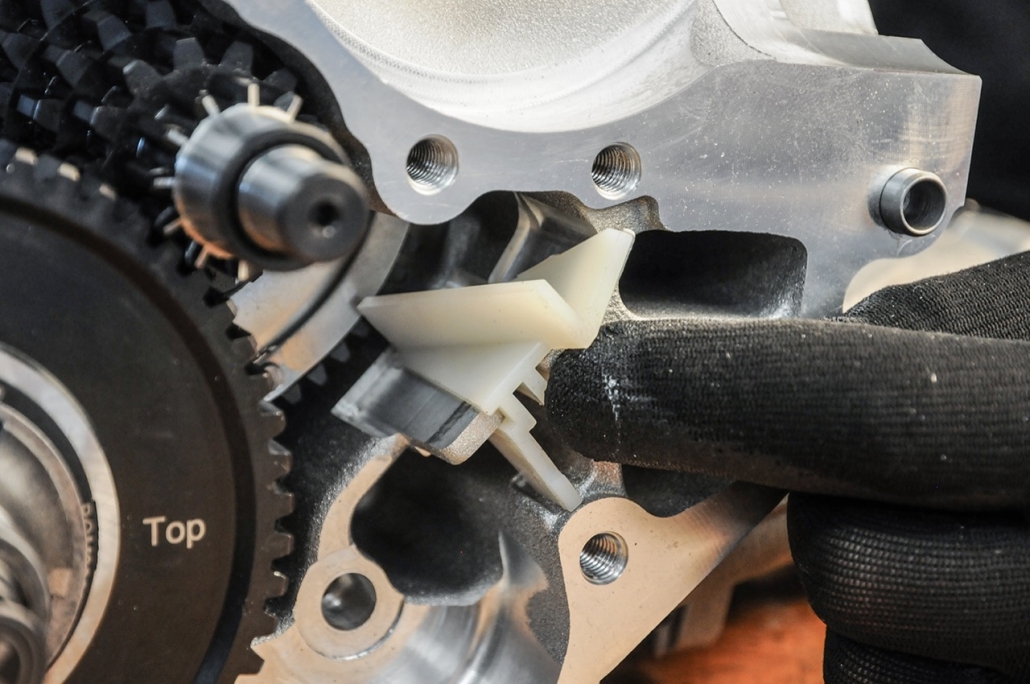

Here is the "experimental setup".

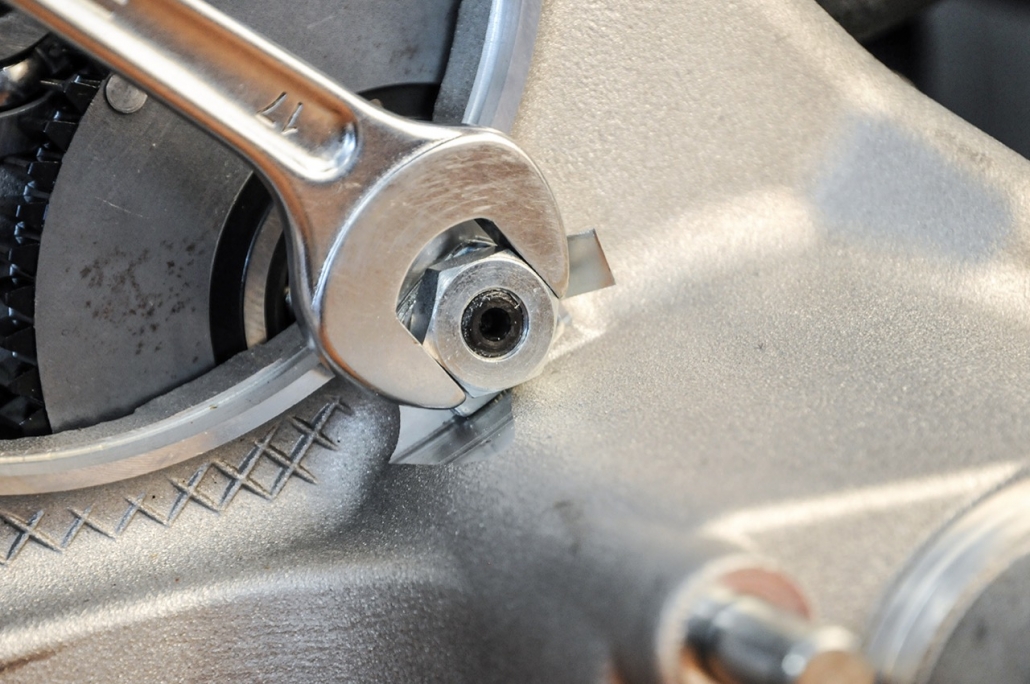

The train is guided and fixed with two and a half strokes around a pulley.

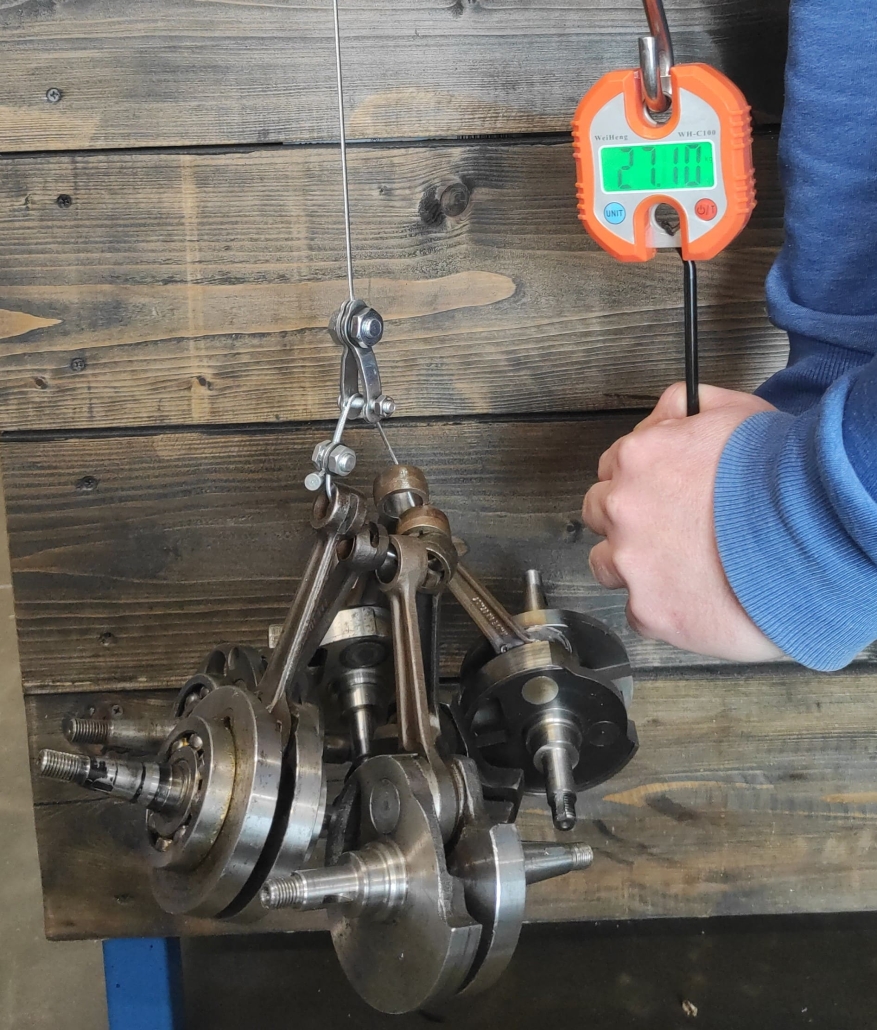

To simulate the train operating a clutch, I hang a corresponding counterweight on one side of the train and to get the value of the required pulling force, a tension scale on the other side of the train.

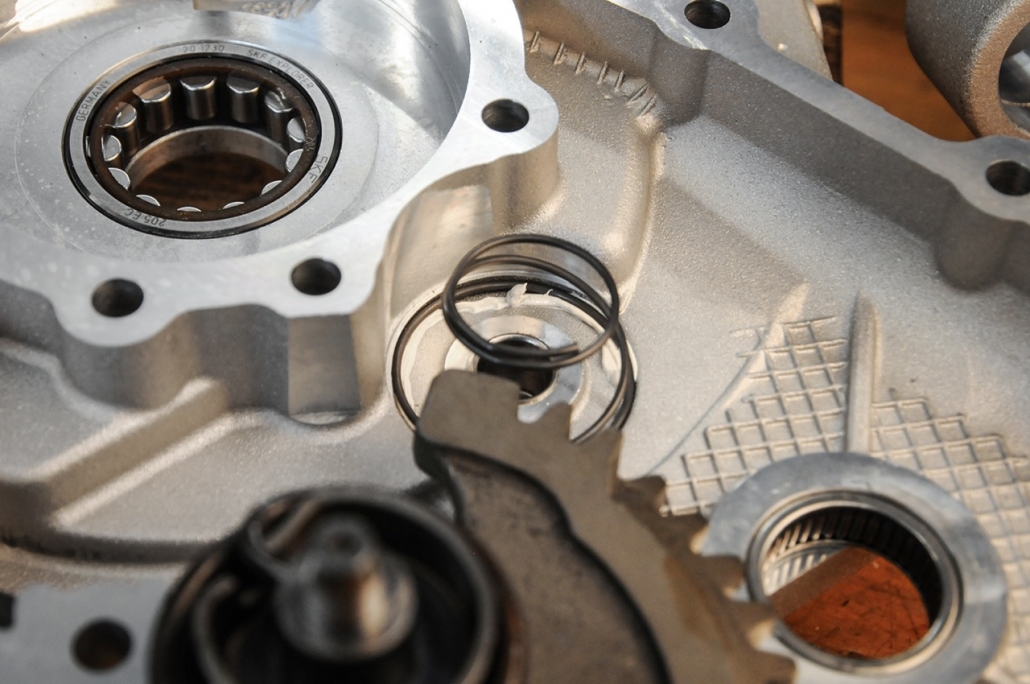

My first example is a completely normal, new standard cable, as can be found in almost every old Vespa. This cable does not have an inner liner that reduces friction, but here the cable runs directly on the steel windings of the outer casing (Bowde) and is only lubricated with grease.

Here more than 70kg are needed to overcome the breakaway torque of the train and to evenly move the small package of crankshafts with only 10kg on the other side.

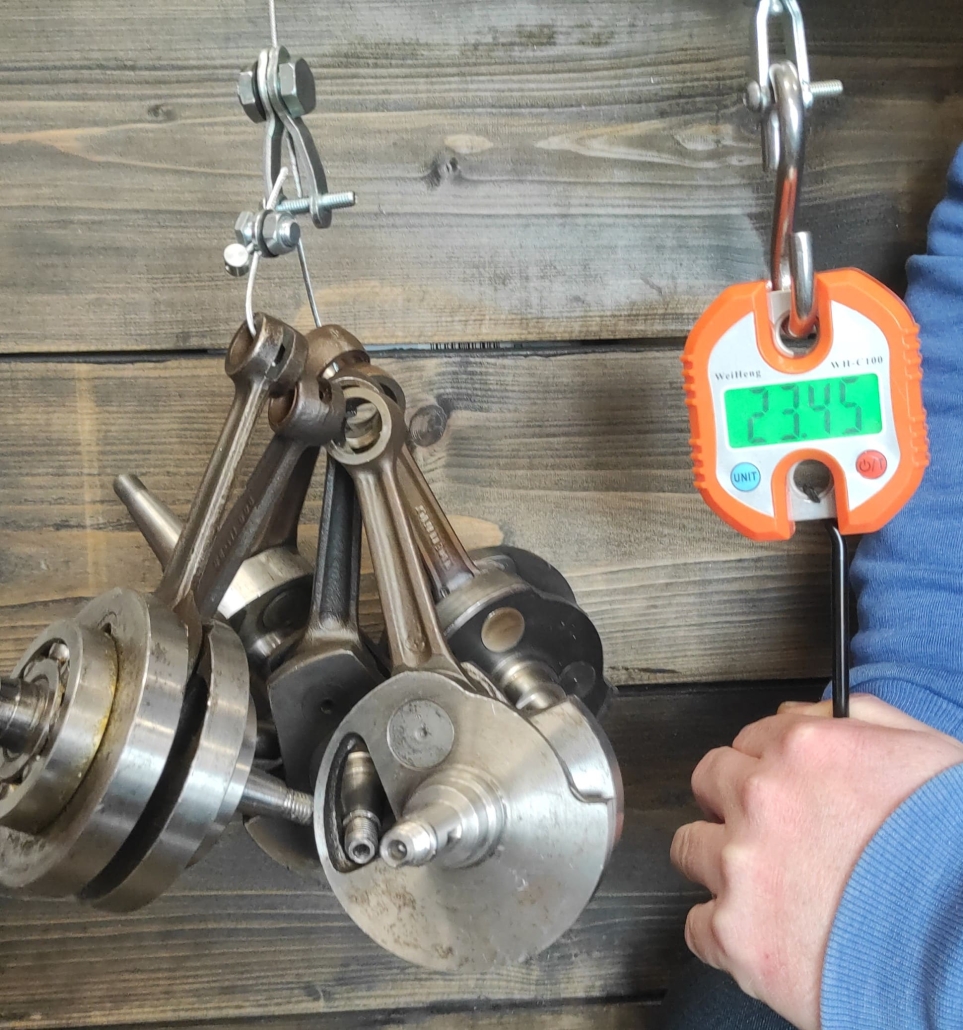

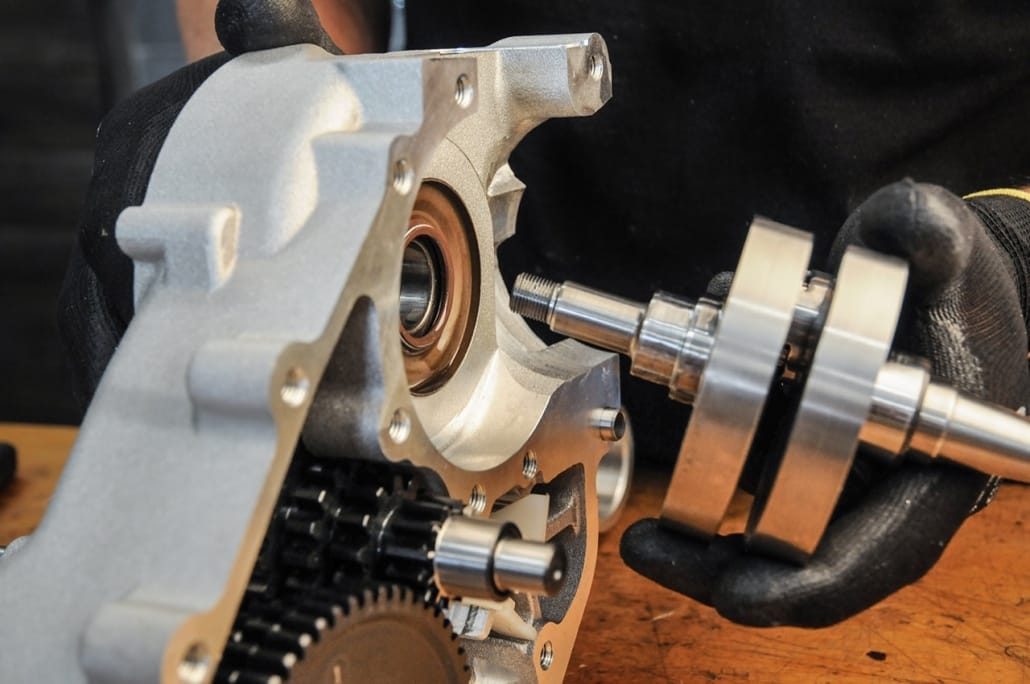

On the third try I put that bgm Silkliner with two and a half strokes around the roll.

The good result of the performance train was once again undercut by the Silk Liner.

Due to the very slippery liner inside, the weighty package of crankshafts can be lifted with only 23.5kg of pulling force.

Transferred to the lever ratios on the vehicle, this further, considerable reduction in the necessary traction helps to ensure a high level of operating comfort and a pleasant driving experience.

In the bgm Pro Silk Liner In addition to ensuring the lowest possible operating forces, we also paid attention to many other details. Over the years and many thousands of scooter kilometers, we have put the experience we have gathered into the composition and production of the bgm Pro Silk Liner cables and cable sets.

We are proud that we can now offer you the bgm Pro Silk Liners probably offer the smoothest cable sets for shifting scooters.

We offer the bgm Pro Silk liner train sets for the following vehicles:

- We offer the bgm Pro Silk liner train sets for the following vehicles:

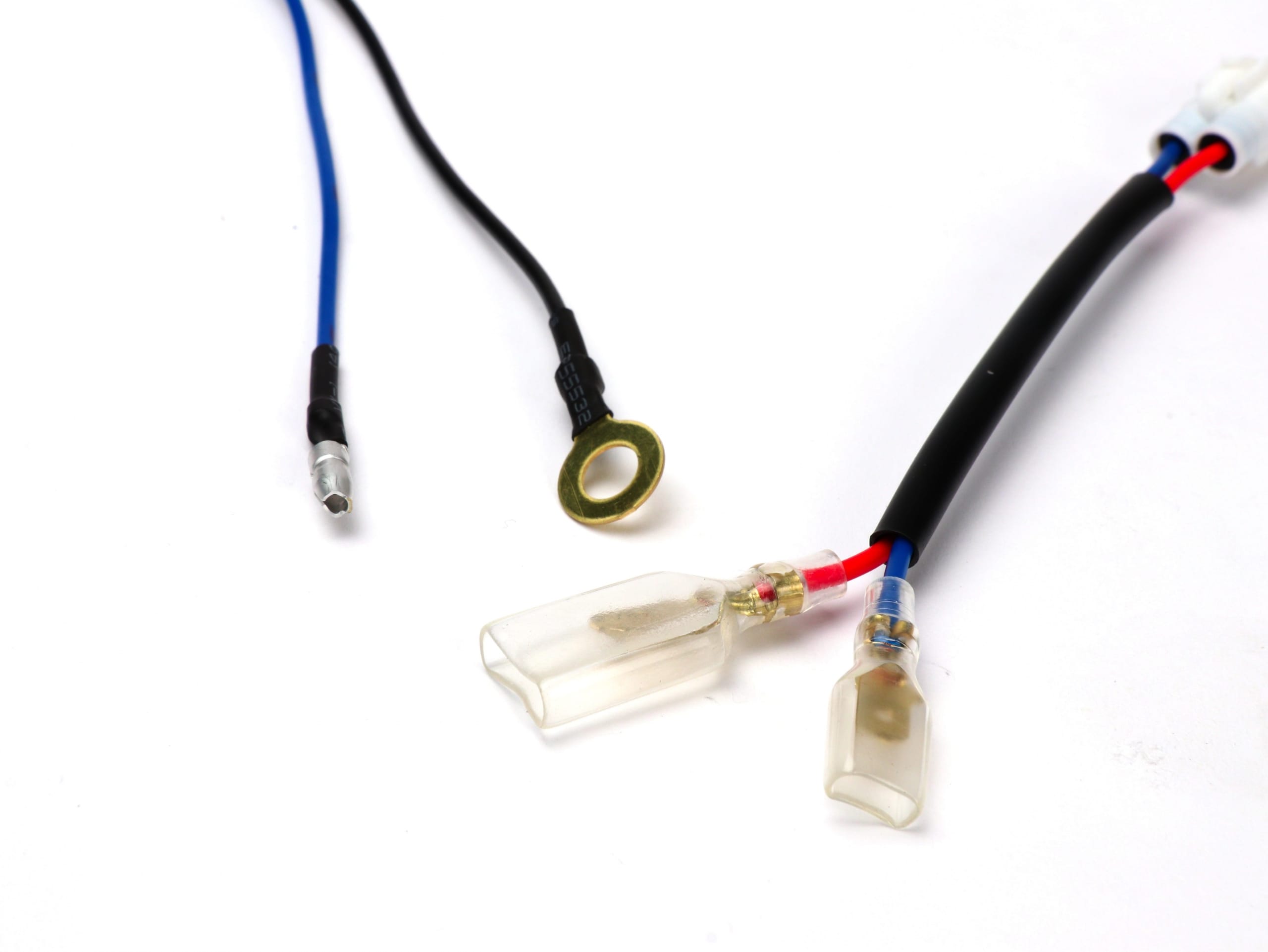

- BGM6460SL Cable set -BGM PRO, Silk Liner- Vespa V50, V90, PV125, ET3

- BGM6470SL Cable set -BGM PRO, Silk Liner- Vespa Rally180 (VSD1T), Rally200 (VSE1T), Sprint150 (VLB1T), GT125 (VNL2T), GTR (VNL2T), TS125 (VNL3T), GL150 (VLA1T)

- BGM6412SL Cable set -BGM PRO, Silk Liner- Vespa PX Lusso (1984-) – black

- BGM6410SL Cable set -BGM PRO, Silk Liner- Vespa PX Lusso (1984-

- BGM6422SL Cable set -BGM PRO, Silk Liner- Vespa PX old (-1984) – black

- BGM6420SL Cable set -BGM PRO, Silk Liner- Vespa PX old (-1984)

- BGM6430SL Cable set -BGM PRO, Silk Liner- Vespa PK XL2 – without gear cable

- BGM6440SL Cable set -BGM PRO, Silk Liner- Vespa PK XL1

- BGM6450SL Cable set -BGM PRO, Silk Liner- Vespa PK S

- BGM6465SLB Cable set -BGM PRO, Silk Liner- Piaggio Bravo