Posts

Kingwelle - A visit to friends

Powerful Vespa engine tuning without a crankshaft from king wave?

Difficult to imagine today, quite normal over ten years ago.

When the SC team sat together in the regular meeting to evaluate new product ideas, the subject of crankshafts and their durability boiled up again. From a technical point of view, a very critical component that is completely undersized in terms of design for the power and torque values realized today.

Our bgm Touring rotary valve crankshafts for the PX have reached a very high level - for serial production - thanks to many improvements that have been incorporated into production (e.g. improved fit on the crank pin, bonding of the same) and can be used without hesitation for touring engines around 25 HP and above .

In our meeting, however, the question of high-end material still remains in the room. What should you take for the diaphragm-controlled motors with 40 HP and more that are now appearing more and more frequently?

Our SC technical director Alex is in constant but loose contact with the two Cramer brothers Christoph and Michael von Kingwelle. A name that has often caused a sensation in the racing scene with its extremely powerful engines and many victories. The contact is established and the guys can also build good crankshafts ...

The SC Technik team is soon invited by the masterminds from Kingwelle to Lindau on the beautiful Lake Constance.

In the most beautiful winter weather we make our way south!

To come to the point: with some encounters you get annoyed very quickly that they did not take place years before.

To come to the point: with some encounters you get annoyed very quickly that they did not take place years before.

THE CRAMER BROTHERS AKA KINGWELLE

Christoph and Michael, two absolutely personable and down-to-earth guys, combine hospitality, competence and joie de vivre in a really unique way. The chemistry between the SC team and Kingwelle is right from the start and so we are invited into the sacred halls of Kingwelle production. It is always astonishing how many details have to be considered down to the smallest detail in a supposedly boring component like a crankshaft.

If the end product is to come out on the quality level of a Kingwelle crankshaft, a completely different consideration is required.

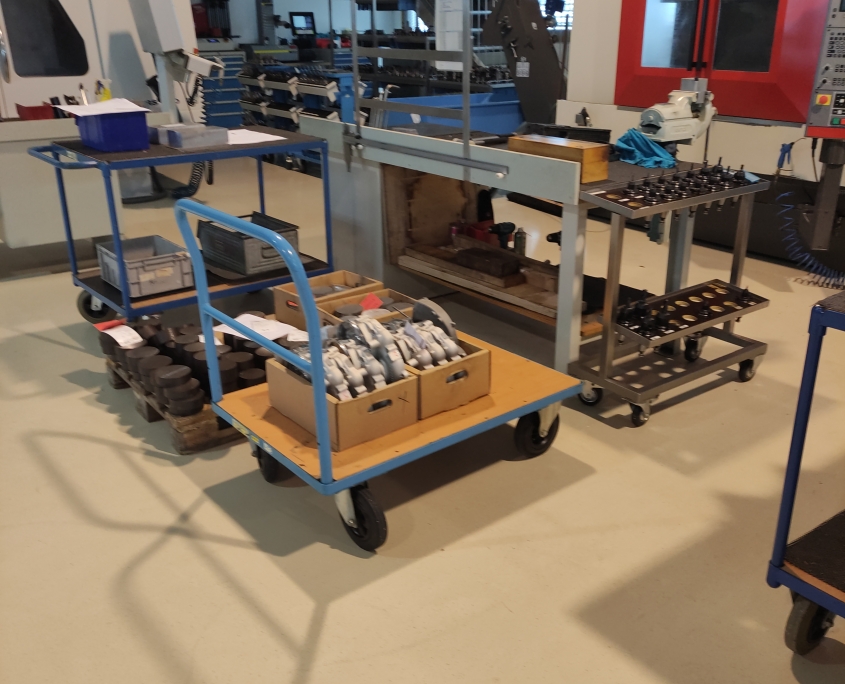

PICTURES FROM THE KINGWAVE MANUFACTURING

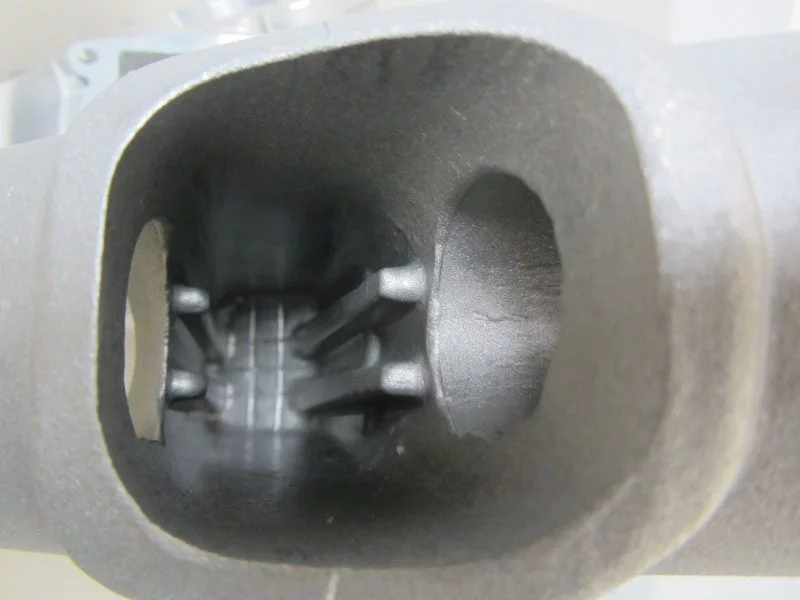

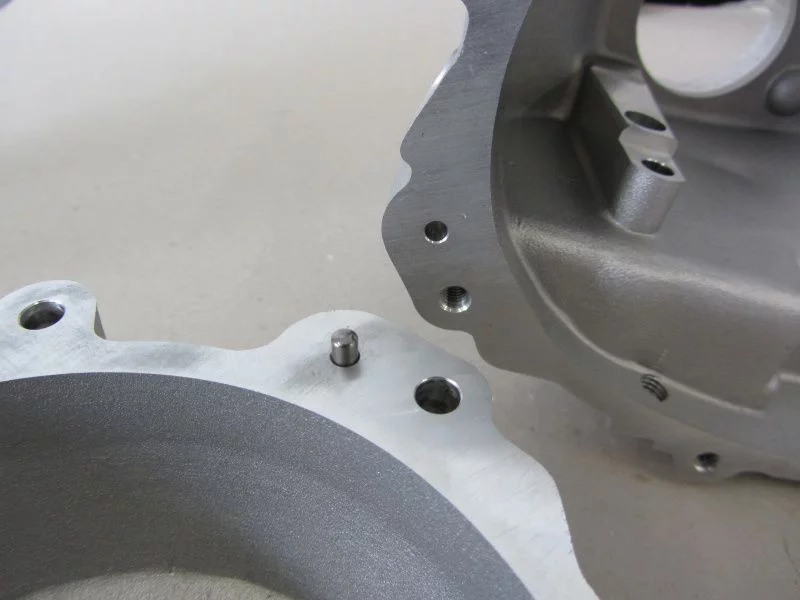

We receive an intensive introduction to the entire production process of the king shaft manufacturing. The many complex production steps astonish even us, but also make it clear why the Kingwelle crankshafts have such a good reputation. Impressed by the size and quality of the machine park, the King coupling is spoken of by the way. We will take a closer look at them together with the technology of the Kingwelle in an extra blog post. Here, too, quality is the top priority and the work processes invested are not immediately apparent, but absolutely necessary. Typically Kingwelle.

When Christoph shows us his private workshop, our chin (g) folds down again.

Several Kingwelle / BFA engine cases including Kingwelle 244 ccm cylinder for Vespa Smallframe radiate towards us. In addition, the super successful DBM / Quartermile Sprinter with rotary knife gate valve and snowmobile cylinder (with over 70PS) as well as more of Christoph's and Michael's scooters with, of course, more than powerful engines.

This is also the birthplace of the Kingwelle products. Christoph and Michael always had so much power in their engines that they completely overwhelmed the then commercially available goods. In order to stay on top of the podium, the two began to create their own products, blessed with good knowledge through their jobs in industrial production.

They only have one task; To function and maintain even under the toughest conditions. Their countless trophies and successful engines that are equipped with Kingwelle products are the great result of many years of hard development work.

QUALITY, QUALITY, QUALITY ...

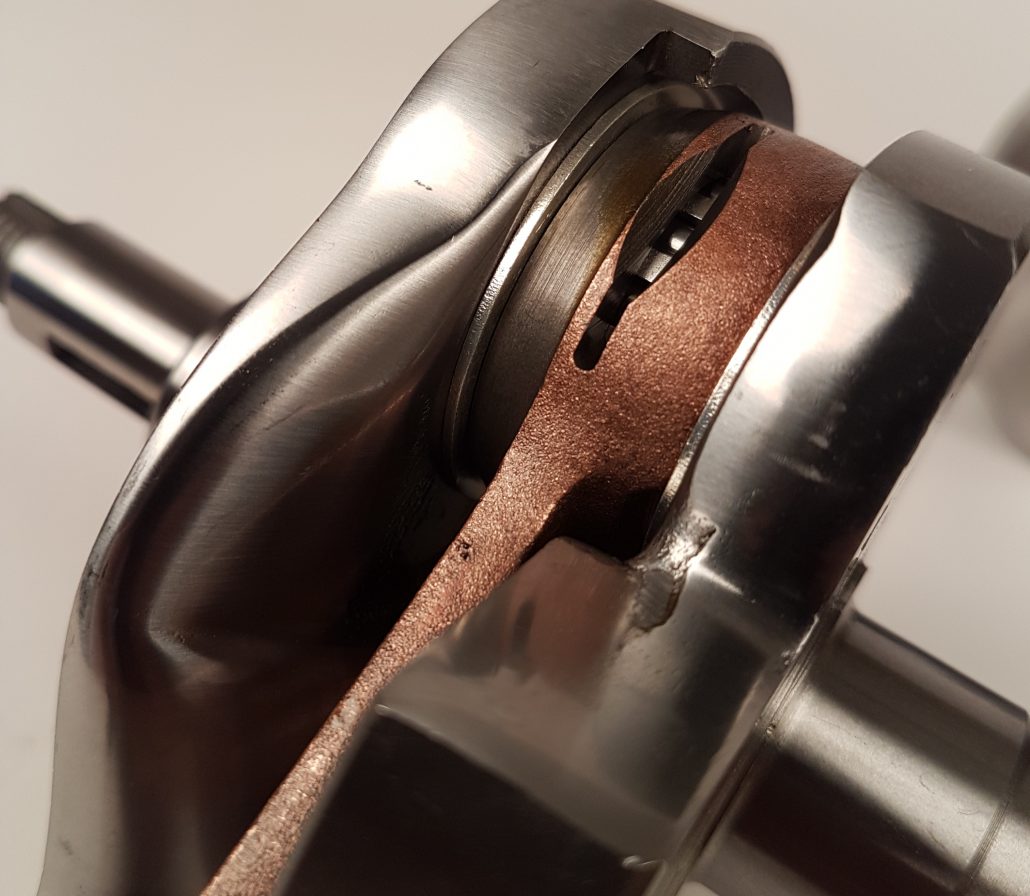

Christoph then also shows us his 'home office', a hydraulic press and associated equipment. In many hours of heavy manual work, the crank webs become a Kingwelle total work of art. As is usual in the 'crankshaft business', it takes experience as well as strength to bring a crankshaft to perfect concentricity with a soft copper hammer. If the terms “hammer” and “crankshaft” in combination sound absurd for many at first - despite all high-tech - this is the only way to go. It takes a lot of experience and skill to bring a crankshaft running with 3 / 100mm to 1 / 100mm. Here, too, you can see how much passion the two brothers put into making their crankshafts. Each shaft is manufactured as if it were for your own motor. There are no exceptions. If something is not 100%, it will be sorted out immediately.

A way of working that creates trust.

GOOD PRODUCTS EVERYWHERE

Somewhat overwhelmed by the depth of production and the many, enormously exciting things Kingwelle tuning equipment, we went over to the cozy part of the evening. We were allowed to enjoy homemade focaccia at Augustiner Bräu Michaels, an absolute dream! It's interesting how many good tuners are also excellent cooks! Whether nozzles or spices, voting is always the be-all and end-all;)

A few schnapps later, we went to our quarters with cool and clean sea air. As city dwellers, we're not used to ...

ATTENTION: ADVERTISING;)

At this point we just have to do some surreptitious advertising. In addition to his normal job and the production of the king shaft parts, Christoph also managed to build an absolute dream house with a view of the lake. Since he is a man of action, he has added something so that you can also go on vacation here (www.tante-idas-fewo.de).

After a more than restful night, the boys insisted on serving us a hearty Bavarian veal sausage breakfast. We were almost moved to tears, this is how it is to live! Thanks again! At least now we realize that we should have visited the boys earlier and at scooter temperatures with our Vespas.

Finally, a joint sight seeing at the 'lake' followed. Living where others go on vacation, that's all you can say about it.

- From left to right: Michael Cramer, Alex Stroh, Ulf Schröder, Uwe Schneider, Christoph Cramer

SUMMARY

So one can say, in spite of the short time; 'We came as strangers, we left as friends'. From a technical as well as a human side, we have become absolute Kingwelle fans. With the immense background knowledge imparted, we now have a perfect partner at our side, whom we can trust blindly and whose products we can recommend without reservation to anyone who would like to receive a perfect product for a fair price.

Always true to that Kingwelle motto: "The best is just good enough!"

The excellent Kingwelle products can now be found in our Online Store.

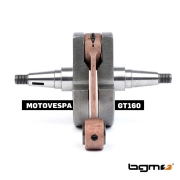

Vespa Wideframe Tuning crankshaft

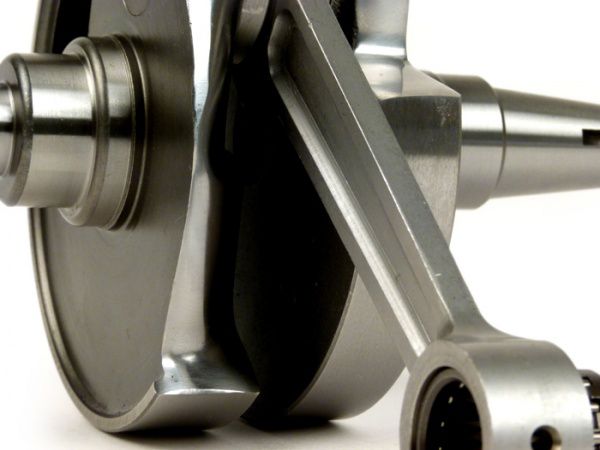

The bgm PRO crankshaft is optically based on the purpose-built design of the 50s and offers all the advantages of modern materials and manufacturing methods. with 57 mm stroke and a 110 mm connecting rod it is perfect for converting all 2-channel motors from 54 to 57 mm and thus the To enable assembly of a tuning cylinder.

We have developed an extremely resilient tuning crankshaft for the highest demands!

The forged crank webs are adapted to the balancing factor for the cylinder and piston used for tuning by means of compensating bores and offer a particularly good running smoothness even at a higher speed level of the more powerful engines. The high surface quality not only offers an impressive look, the ground surfaces also ensure a long service life for the shaft sealing rings and a reliable fit of the crankshaft bearings.

High-alloy forging blanks had to serve this noble BGM PRO crankshaft for Vespa Wideframe Models could arise. This shaft is ideal in connection with the BGM PRO 150cc Vespa Wideframe Tuning cylinder.

You don't even want to tune your old Vespa? This wave is of course also called a quasi indestructible wave for original engines a clear recommendation.

The bgm PRO crankshaft offers a stronger connecting rod with high quality bearings. The lower connecting rod bearing is flanked by robust thrust washers and is therefore sufficiently dimensioned for higher speeds and outputs. Generous lubrication slots and pockets ensure an optimal supply of the lower bearing with the important lubricant. With the use of a needle bearing instead of a traditional gunmetal bushing for the piston pin, the bgm PRO crankshaft offers another decisive advantage for creating a permanently powerful engine. For a better oil supply, there are also lubrication holes in the upper connecting rod eye, which absorb the centrifugal oil and pass it on to the piston pin bearing.

Modern technology for the old engine

A big advantage of the BGM PRO crankshaft compared to an original one is the use of a high-quality connecting rod with needle bearing (instead of a plain bearing bush) and a slotted lower connecting rod eye. This significantly reduces the oil requirement so that the engines can use today's high-quality oils without any problems 1:50 mixture can be driven.

The balancing factor was improved, among other things, by a hollow crank pin.

- Hub: 57mm

- Connecting rod length: 110mm

- Piston pin: Ø15mm

- Connecting rod bearings: needle bearings (top and bottom)

Suitable for 125 and 150 Wideframe Vespa engines

The crankshaft is suitable for all 125ccm and 150ccm engines. The 125ccm engines only have a stroke of 54mm ex works, so a cylinder is required here that is designed for 57mm stroke (BGM1550, Pinasco North Cape).

The BGM PRO Vespa Wideframe crankshaft fits in the following vehicles:

- Vespa: VM, VN

- ACMA: 125 (70191-295883), GL150

- Motovespa 125N, 125S, V56, V58, V72

- Douglas GL2, 42L2, 92L2

Tip:

You can find more interesting products for your Vespa oldtimer in our Vespa Wideframe Catalog DOWNLOAD

Now here is your new one Wideframe Buy crankshaft

bgm PRO Competition - the new bgm Lambretta cure shaft

When good gets even better:

We have revised our Lambretta crankshafts. Working with our new manufacturer took almost three years. We are very happy with the end result. The tests lasted as long as the development work.

The new Lambretta crankshaft is available in 58 mm and 60 mm stroke and with connecting rod lengths of 107 mm, 110 mm and 115 mm:

- https://www.scooter-center.com/product/BGM10758N

- 60mm stroke, 107mm connecting rod >> BGM10760N

- 58mm stroke, 110mm connecting rod >> BGM11058N

- 60mm stroke, 110mm connecting rod >> BGM11060N

- https://www.scooter-center.com/product/BGM11558N

- https://www.scooter-center.com/product/BGM11560N

Tried and tested in racing

Darren Conneely from Team Replay successfully used the new bgm PRO Competition crankshaft in BSSO races in the 2018 season. The Lambretta Group 4 Racer with one bgm RT 195 cylinder Kit and the new bgm PRO Competition shaft was made by Paul “Chalkie” White from Team replay built. A real stress test with over 30 hp on the rear wheel and speeds of up to 11.000 rpm.

So while we were testing the crankshafts extensively on the road, Darren raced with the new crankshaft to 2nd place in group 4. Congratulations!

60mm stroke, 110mm connecting rod

Crankshaft -BGM Pro HP Competition 60mm stroke, 110mm conrod- Lambretta DL / GP 125cc, 175cc, 200cc, 225cc, 250cc

Article no.: BGM11060N

60mm stroke, 107mm connecting rod

Crankshaft -BGM Pro HP Competition 60mm stroke, 107mm conrod- Lambretta DL / GP 125cc, 175cc, 200cc, 225cc, 250cc

Article no.: BGM10760N

58mm stroke, 110mm connecting rod

Crankshaft -BGM Pro HP Competition 58mm stroke, 110mm conrod- Lambretta DL / GP 125cc, 175cc, 200cc, 225cc, 250cc

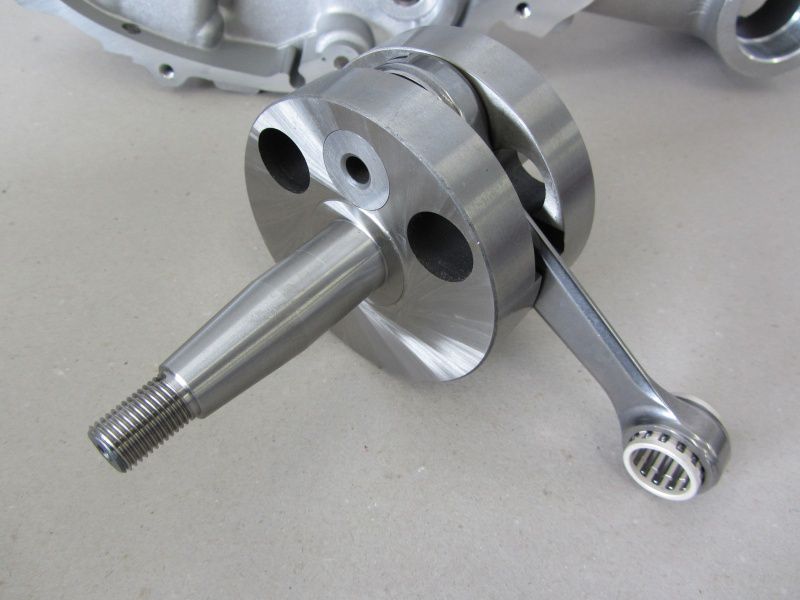

The features that have proven themselves have remained! Important technical details have been further improved.

Improved features are for example:

- Ground pressing surfaces for maximum stability of the joint and therefore the highest possible security against rotation

- Ground and coated crank pin

- Forged connecting rod with CNC finishing

- Hardened and ground bearing and shaft seal seats

- Wider selection of stroke and connecting rod combinations than before

- Quality assurance of every single crankshaft through 100% testing by ISO and QC certified manufacturers

What remains are:

- Full cheek wave for increased pre-compression

- Forged crank webs

- Low-vibration motor operation thanks to ingenious balancing with hidden pockets, counterweights made of copper and tungsten

- Lubrication of the lower connecting rod bearing via two large lubrication slots

- Crank pin diameter 22 mm

15 years of experience in crankshaft development

Stick in the bgm PRO Competition shafts 15 years of experience in total. In the optimization three more years of development work and tests in order to be able to realize a wave that maximum security against rotation and stability offers.

In the English BSSO racing series, the Replay team started the 2018 season with a number of bgm parts. Among other things with the new and revised bgm crankshaft. Replay's driver Darren Conneely finished second in Group 4.

Crankshaft bgm PRO Vespa

The coveted bgm PRO crankshafts Vespa for Vespa PX, Vespa PK and Vespa V50 are now available again.

Practical revision kits for Vespa engines

We offer you in our Scootershop on cheap revision kits. The practical sets contain all the parts you need to overhaul your Vespa engine:

Vesps revision kits

Our tip: bgm PRO Protection gloves

We recommend ours to protect against injuries and dirty fingers Work gloves by bgm PRO

Buy Vespa crankshaft here

Crankshaft Vespa PX80

Many of you still know and may have discovered your love for the Vespa on this scooter:

The Vespa PX80, which was built by Piaggio only for the German market.

80cc - the German way

With the fall of the old regulation valid in Germany until 14.02.1996/80/80, 80ccm up to a maximum of 80km / h, the sale of the PXXNUMX in Germany was also discontinued. Unfortunately, the spare parts supply from Piaggio became very scarce. For a long time there was no alternative to the expensive, original and difficult to find Piaggio PXXNUMX crankshaft.

In the meantime, however, the PX80 has also stood out from the shadows behind the PX200, which is favored in Germany, and there is a loyal fan base for the smallest motor from the PX family.

Vespa PX80 tuning

With the appropriate components, however, the PX80 can again experience an enchanting second or third spring and catch up with the performance of its big sister.

Well-known friends are here “The 139er” from Malossi and “The 135” by Diffusione Ricambi, DR for short.

While Pinasco tried to add a shovel with the 149 aluminum cylinder, Polini never tried the PX80.

Vespa PX80 crankshaft - the weak point

No matter which cylinder drove the unit of the PX80, the original crankshaft went the usual way: it quit service due to the loss of the thrust washers and the resulting death of the lower connecting rod bearing - good advice was expensive.

The solution: our Vespa PX80 crankshaft from bgm PRO

You will learn from experience, which is why we have the easy-to-turn PX80 with our bgm PRO Crankshaft for Vespa PX80 donated a set of sturdy thrust washers.

With the bgm crankshaft there is finally a suitable replacement for the PX miniature motor.

With the bgm standard crankshaft with 48mm stroke, there is only a very slightly longer intake time.

Other crankshaft manufacturers design a much too large opening angle for the PX80, the result is that the cylinders with the small control angles in connection with the small inlet provided by the "anti-tuning bores" no longer run usefully in the lower speed range. The tunability of such motors also suffers due to the large opening angle.

Also available as a long stroke shaft Vespa PX80

So that screwing on the PX80 is fun again, we also have a "Long stroke version”Placed on the bgm crankshaft.

With 51mm stroke On the small engine, other performance values can be achieved and the existing cylinders benefit from the increased control angles.

Order crankshaft for Vespa PX80 here

Comparison of long-stroke and standard shaft

Here is a quick comparison when using the different cylinders on 48mm and 51mm stroke.

| Series stroke 48mm | Outlet angle ° | Overcurrent angle ° | Advance ° |

| DR135 | 155 | 115 | 20 |

| Malossi 139 | 182 | 120 | 31 |

| SC conversion cylinder 125ccm | 155 | 110 | 22,5 |

| Long stroke 51mm | Outlet angle ° | Overcurrent angle ° | Advance ° |

| DR135 + head gasket 1,5mm | 158 | 121 | 18,5 |

| DR135 head gasket 1,5mm (+ 2mm outlet height) | 168 | 121 | 23,5 |

| Malossi 139 head gasket 1,5mm | 184 | 126 | 29 |

| Malossi 139 head gasket 2,0mm (foot -0,5mm) | 182 | 124 | 29 |

| SC conversion cylinder 125ccm head gasket 1,5mm | 158 | 117 | 20,5 |

| SC conversion cylinder 125ccm head gasket 1,5mm (+ 2mm outlet height) | 168 | 117 | 25,5 |

Tip: Pay attention to the correct translation

If the PX80 is equipped with a larger cylinder, the Primary reduction be changed.

The PX80 has the shortest version with 20/68 teeth. For the original clutch with 6 springs and a diameter of 108mm Clutch pinion available with 21, 22 and 23 teeth.

A clutch for life:

Alternatively, the entire clutch can be exchanged. Also the BGM Superstrong Fits into the PX80 after a few small changes and can be operated with the primary wheel of the 80s. Here, too, there are variants with 20, 21, 22 and 23 Teeth.

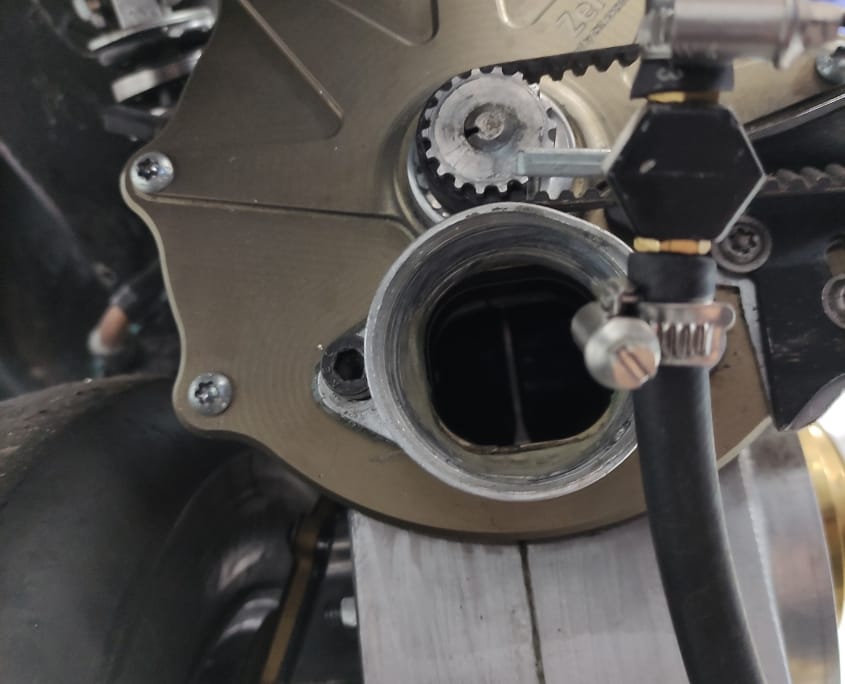

New crankshaft bgm PRO for Vespa PX 125 and Vespa PX 200

We are working on a new version of the bgm PRO crankshafts for the PX engines. We have already installed the first samples in our engines for testing.

With the new version of our coveted bgm PRO crankshafts for Vespa, we have Maintain the tried and tested and few but distinct improvements performed.

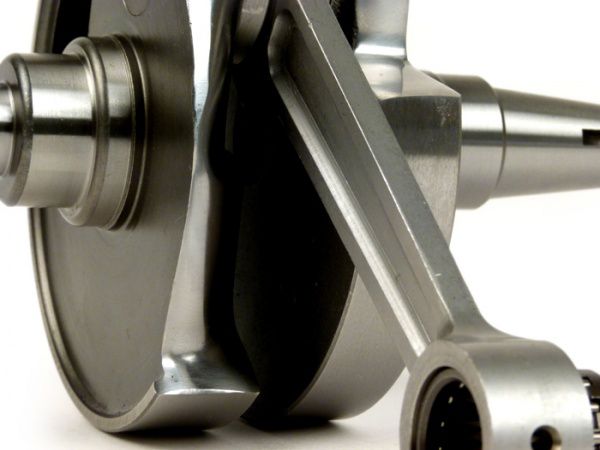

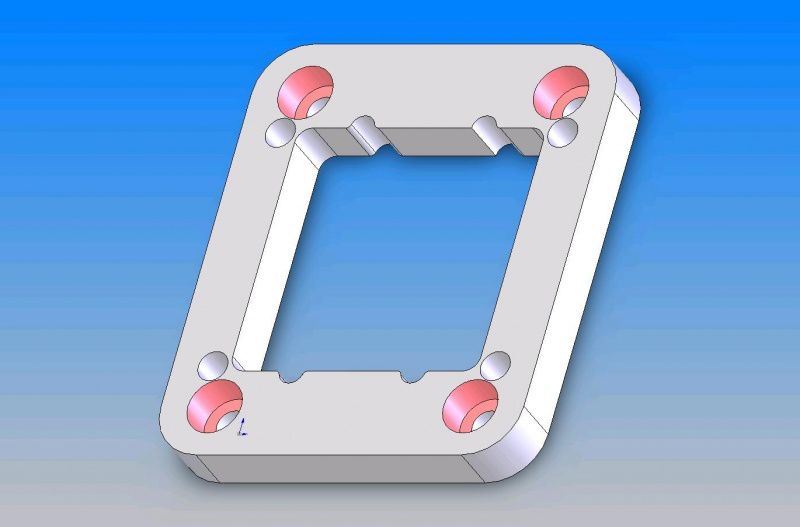

Connection between crank pins optimized

Vespa crankshafts - bgm PRO im Scooter Center Blog.PURE SCOOTERINGblog.scooter-center.comWe paid special attention to the connection between the crank pin and the crank web. The quality of this connection determines how durable and reliable a crankshaft runs.

By redesigning both partners in the press fit, the crank pin and the crank webs, we have provided significantly more press surface and thus a secure connection.

We have only changed the design of the crank web in the inlet area slightly.

On the Vespa PX200 engines the tried and tested fitting angle remains until the inlet closes approx. 65 ° after TDC.

The connecting rod has also been changed. New material and changed dimensions make the highly stressed component of the Vespa engine reliable and stable.

We have retained the previous features of the bgm PRO crankshafts.

With the wider rotary valve surface, a larger inlet area in the motor housing or, alternatively, a wider coverage of the rotary valve sealing surface can be implemented.

The shaft seal seats are designed to be easy to assemble; folding over or damaging the sensitive sealing lips is almost impossible. In addition, the shaft sealing ring seat on the generator side is manufactured in such a way that shaft sealing rings made of FPM with an upstream dust lip can be used sensibly.

We are still testing the crankshafts

Unfortunately, we cannot tell you when exactly the new version of the bgm Pro crankshaft will go on sale. We still have a few test kilometers to do and are still looking into a few changes.

But we are sure that we will be able to offer THE rotary valve crankshaft for your Vespa again very soon.

New and good at a glance

- wide rotary valve surface

- optimal inlet angle for rotary vane motors

- Flow-optimized inlet area of the crank web

- improved interference fit

- optimized oil seal seats

- stable connecting rod with lubrication slots

- lower connecting rod bearing with silver cage

- forged crank webs

New crankshafts for Vespa PX 125 and Vespa PX 200

The new version of the bgm PRO crankshafts will be available in 57mm and 60mm stroke for the PX125 and PX200 engines.

Current crankshafts bgm PRO VespaNew Polini Vespa crankshaft

Polini Vespa crankshaft at Scooter Center arrived!

The brand new Polini crankshafts for the Vespa PX engines have just arrived.

Now available in Scooter Center Vespa shop. The is currently available Polini Vespa crankshaft for:

- Vespa PX200, stroke 57mm, 110mm connecting rod

- Vespa PX200, stroke 60mm, 110mm connecting rod

- Vespa PX125, stroke 57mm, 105mm connecting rod

In detail

We took a closer look at the new Polini Vespa crankshafts for you.

First of all, the shape of the rotary valve cheek is striking. Here was a lot of material out of the way.

The relative is also noticeable strong cutwhich ensures a very quick intake closure and does not propel mixture out of the crankshaft housing again via a ramp. In return, the window under the rotary valve surface has been carefully processed so that there is no excessive imbalance within one crank arm.

The PX125 and the PX200 Vespa crankshaft with 57mm stroke is equipped with a 22mm crank pin. The crank webs for 60mm stroke are connected by a 20mm crank pin to ensure sufficient material coverage.

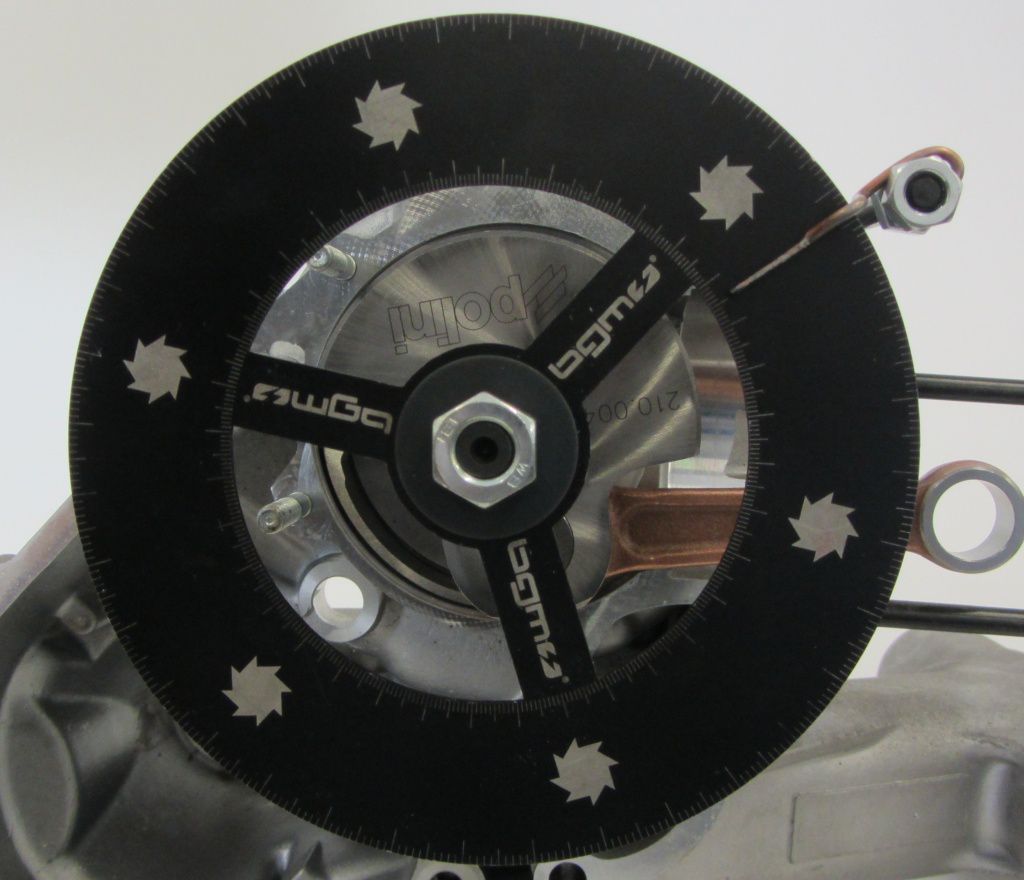

The cutout on the rotary valve cheek determines the period in which the inlet is open.

On a current PX200 motor housing, we come to a value of 110 ° from above. up to 75 ° n.Ot.

Overall, you get a very sporty steering angle of 185 °.

With the PX125 crankshaft we were able to get the values 110 ° from top to bottom. and 63 ° nth with a Degree disc

determine.

Polini has not changed the width of the rotary valve surface and is based on the original at 17mm.

Polini advertises the crankshaft as “balanced”, ie balanced to minimize nasty vibrations.

Therefore, we first looked at the balance factor. As a test victim, the PX200

Use a crankshaft with a 57mm stroke.

On the roller block, the crankshaft oscillates almost at the 12 o'clock position.

The so-called balance factor allows conclusions to be drawn about the expected running smoothness.

If you would like to try something out with the balance factor, we have determined some values.

The translational part of the connecting rod weighs 60,25 grams

The pendulum weight, i.e. the mass that is attached to the connecting rod so that the crankshaft can be brought to a standstill in any position on the roller block, is  104,35 gr.

104,35 gr.

The Scooter Center presents the Polini Vespa crankshaft Vespa PX125 and Vespa PX200.

Quattrini engine Vespa Smallframe

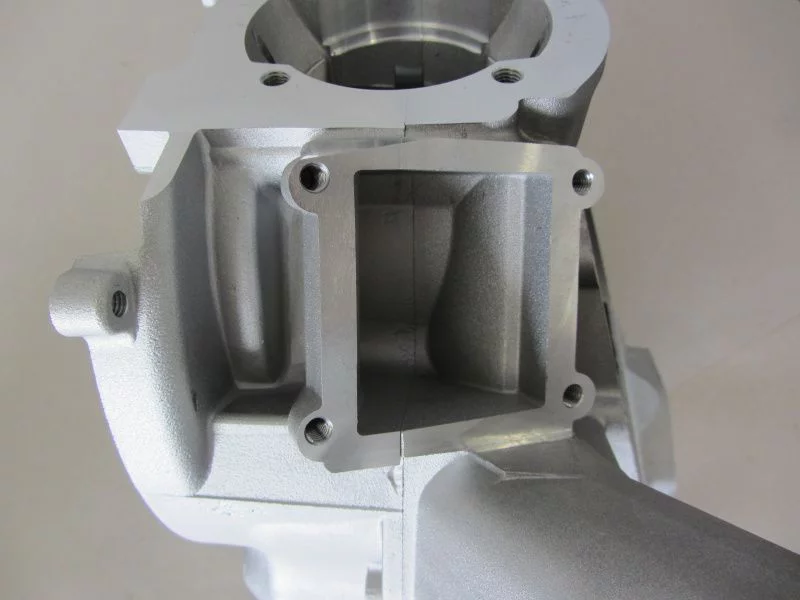

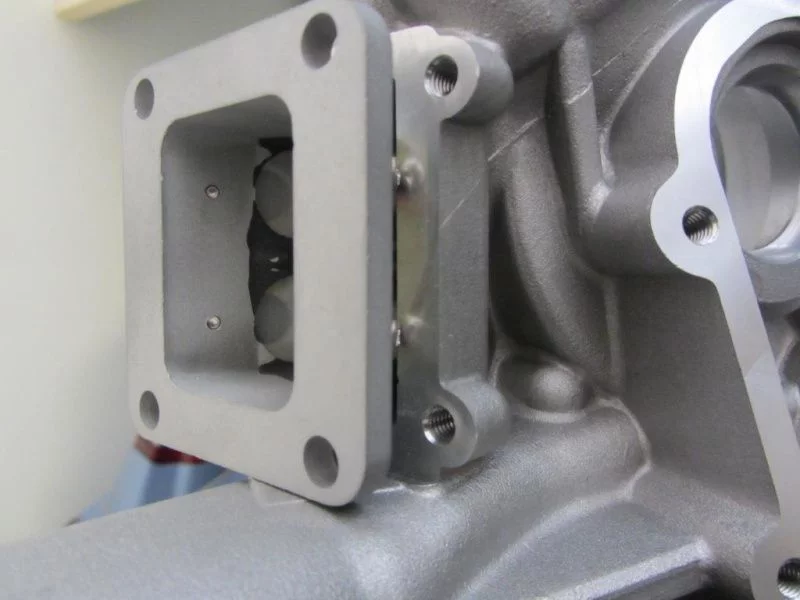

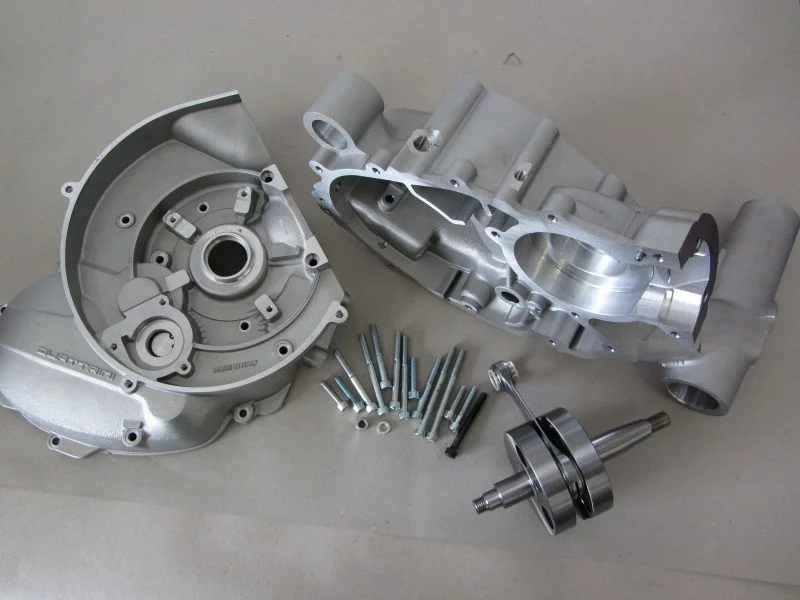

We finally have the new ones Qattrini C1 Smallframe Motor housing get.

A real delicacy delighted everyone with the technology.

Vespa Smallframe >> Power without end

In recent years, the liter output has been in the range of Smallframe Motors kept increasing.

So-called “over 40” engines are no longer uncommon today. The previous Piaggio engine housings, formerly designed for around 10HP, keep this concentrated

Force that PARMAKIT, falc last but not least qattrini hammer on the asphalt, no longer stood.

Quattrini has thus taken the increased requirements into account and developed a very well thought-out motor housing.

Buy Vespa Quattrini crankcaseQuattrini motor housing

We would like to introduce some features to you here.

From the outside, the first thing you notice is the mount for a mechanical water pump to mount water-cooled cylinders.

If you use the classic forced air cooling, an aluminum plug is also included in the scope of delivery to meaningfully close the bore of the pump.

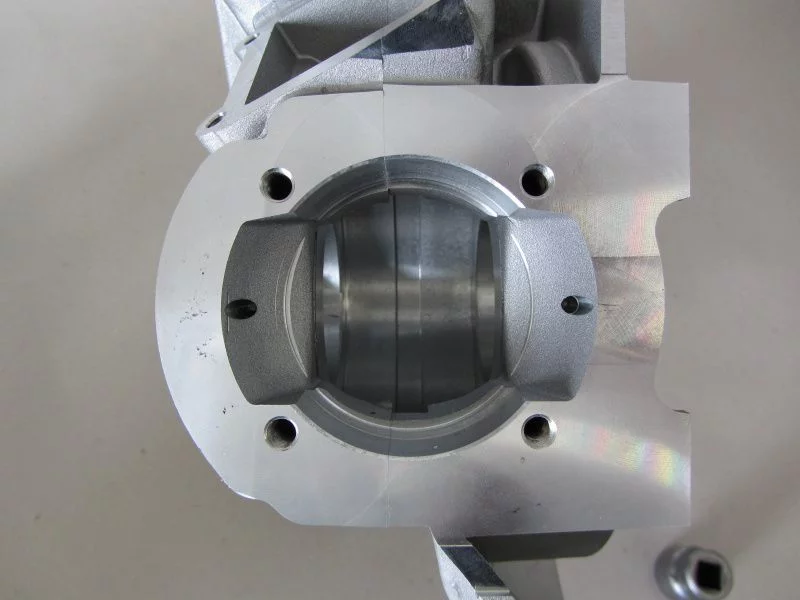

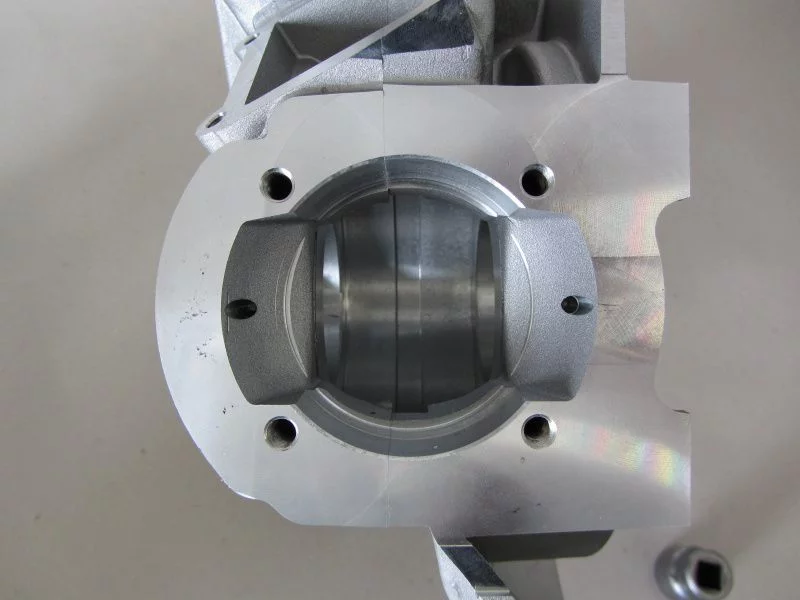

The area around the overflow ducts and the cylinder base is much more massive. Broken housings at this point due to a larger spindle dimension should be a thing of the past.

From Quattrini, the cylinder base is already spindled to a 64,8mm diameter 17,5mm deep.

Below this is an area up to 21mm deep, which is spindled to match the original cylinder base diameter.

In the area of the swing arm, the motor housing is offset without any problems 3.50 × 10 tires can be mounted.

In order to compensate for the weakening of the traverse caused by the heel, it was reinforced from the inside with 4 massive ribs.

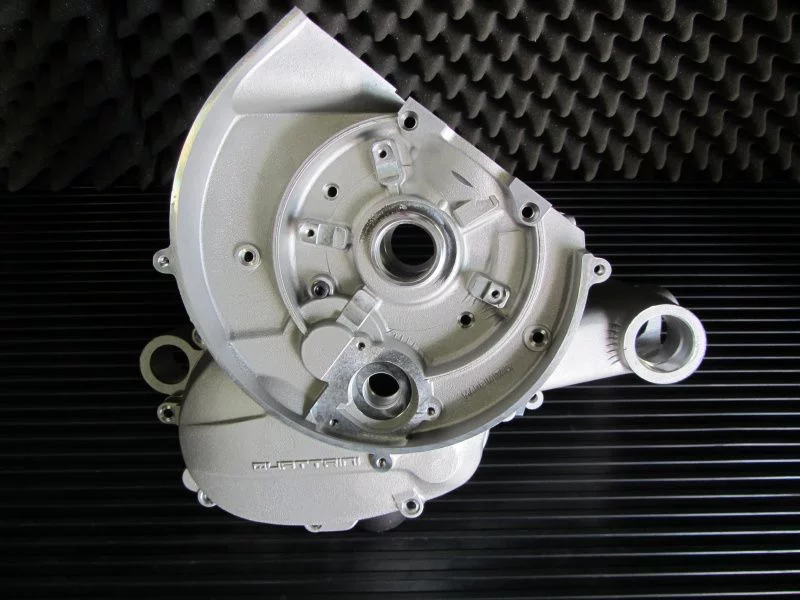

The two halves of the housing are connected with 2 centering pins and M6 screws, so there is no need to handle separate nuts. Due to the cast membrane box and the lack of centering on the crankcase, there is also no need for a housing seal made of paper. As is common today, the engine is simply put together with sealing compound. We recommend based on experience Dirko HT.

In the delivery state, the housing is designed for cylinders with direct suction. For all friends of the case-sucked power dispenser, a membrane box is cast on the Quattrini case.

If necessary, the connection to the crankcase must be milled out in-house.

Unfortunately it is not yet clear which membrane should be used here.

So we have already worked on a solution for one RD350 and V-Force³ Adapt membrane.

In the area of the circuit, Quattrini stays with the tried and tested 2-pull mechanism.

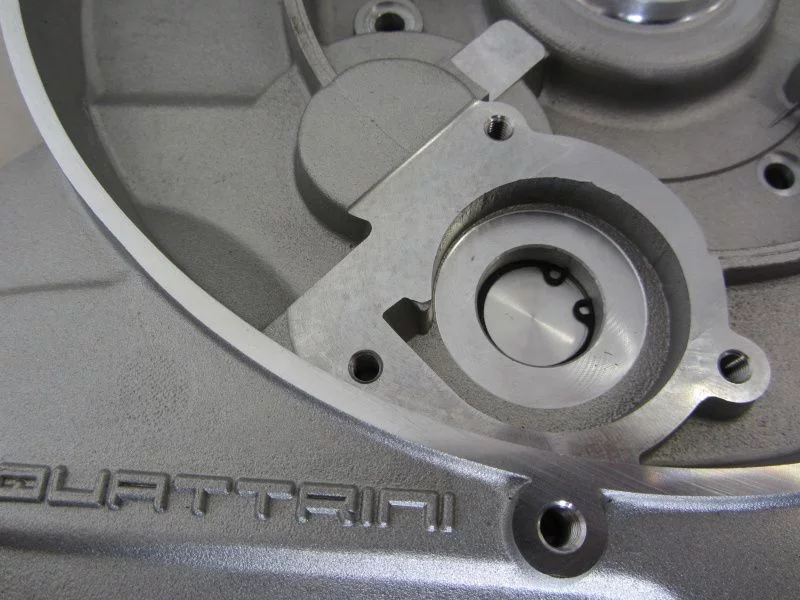

The heart of the entire new design is the 48mm widened crankshaft with 51mm stroke.

This measure ensures that the press size of the connecting rod pin is increased significantly

and the crankshaft leaves nothing to be desired in terms of anti-twist protection.

The high-quality 102mm connecting rod, guided in bearings with a silver cage, rounds off the overall impression. The dimension of the center of the crankshaft bearing and the cylinder base sealing surface is 69mm and is therefore intended for use with the 102mm connecting rod.

Both sides are used as crankshaft bearings 6304TN9C4 is used.

It would also be conceivable to mount a NU205 on the alternator side, however, due to the inertia of the bearing caused by the large rolling elements, we advise against it for ambitious sporty use.

The crankshaft housing is sealed on the alternator and primary side (!) With shaft sealing rings that are accessible from the outside.

With the dimensions 20x35x7 we can offer you this in proven FPM quality .

The shaft seal seats are manufactured with an inner stop. It is therefore practically impossible to mount the shaft sealing rings too deep.

Depending on which one ignition is used on the engine, a hole has to be drilled in the alternator housing for the exit of the cables.

The air duct has already been modified for the use of race exhaust systems.

After the grandiose demonstration of the Quattrini engine housing at the start of the season in Mirecourt, we are excited to see who will be the first in our customer base Quattrini motor housing emotional.

Buy Vespa Quattrini crankcaseThey are finally here! The fat X-treme waves from Airsal. And when the guys from Airsal X-treme say it is that too: 45 mm stroke!!! That gives with one:

- 50 bore a displacement of over 88,3 cc.

- 47,6 bore over 77 cc!

Stroke it baby!

Today in the blog and on the phone: 02238 – 30 74 30 available and the days then also in Online-Shop:

AIR1019X | Crankshaft -AIRSAL X-treme 45mm stroke, 85mm connecting rod- Minarelli 50ccm horizontal (for 12mm piston pin) | 199,00 euros

With the bgm PRO Racing Wave there is finally a racing wave with reasonable timing. The times are 110 ° opening before top dead center and 65 ° closing after top dead center. This finally puts an end to the annoying blowback and the better filling can also be converted into performance. The inlet area of the rotary valve cheek is flow-optimized and polished. The width of the rotary valve cheek is 17,4 mm, making it the only shaft on the market that offers the option of milling really large areas using the rotary valve control.

Racing timing - but correct!

With the bgm PRO Racing Wave there is finally a racing wave with reasonable timing. The times are 110 ° opening before top dead center and 65 ° closing after top dead center. This finally puts an end to the annoying blowback and the better filling can also be converted into performance. The inlet area of the rotary valve cheek is flow-optimized and polished. The width of the rotary valve cheek is 17,4 mm, making it the only shaft on the market that offers the option of milling really large areas using the rotary valve control.

54mm long stroke shaft with forged CNC connecting rod for Vespa Smallframe

Just in time for the start of your 'one stop online shops' we can offer you the revised version of our 54 mm long stroke shaft for the Vespa Smallframe .

The Highend Race Welle runs on several over 30s FALCS completely problem-free. More stroke means more torque and more power. This means that the 54 mm shaft should be the first choice for all engine assemblies where performance is a requirement.

In the bgm Lambretta cure waves it is the best HPC (high primary compression) racing shafts.

In the bgm Lambretta cure waves it is the best HPC (high primary compression) racing shafts.

This shaft has the standard stroke of 58 mm and the standard connecting rod length of 107 mm. This makes the shaft a direct replacement for all Lambretta series 1-3 shafts (with the exception of the TV 175 series 1, 2 and 3).

The balancing of this crankshaft is specially designed for the piston weight of the pistons used on the small engine blocks (up to 64 mm bore).

All bgm Shafts are forged. Both the crank webs and the connecting rod are forged. The connecting rod is also polished.

The crankshaft is considered to be the heart of the engine.

The crankshaft is considered to be the heart of the engine.

You should definitely not make compromises here. We were dissatisfied with the available shafts in close cooperation with bgm reinvented the Vespa PX 200 shaft.

The wave is in two versions.With the Standard tax time with a Racing timing.

The time has come!

We can offer you the new BGM Evo crankshaft with a 55mm stroke.

Over 10 prototypes had to endure tests on the test bench and on the road until we were satisfied with the result.

- the forged Kawasaki connecting rod with a length of 110mm combines low weight with high stability. The length improves the angle at which the force is applied to the bearings and reduces the mean piston speed.

- lower connecting rod bearing with increased load capacity like from the Moto-GP area. The open needle cage reduces the friction and thus the heat build-up in the bearing.

- For horizontal motors, a balance factor of 30% -40% is considered optimal. In the test, the balance factor of 37% in connection with a 172 Malossi piston brought the best results.

- the crankshaft stub on the drive side has been changed, the structure is now 1-part.

- incl. 5mm spacer

[inspic = 82, left, fullscreen, thumb] [inspic = 80, left, fullscreen, thumb] [inspic = 81, leftclear, fullscreen, thumb]

[inspic = 100, left, fullscreen, thumb] [inspic = 101, left, fullscreen, thumb]

[inspic = 8, left, fullscreen, thumb]

The first prototypes for the Big Bore cylinders are here. We will be testing the 44mm stroke shaft with 85mm and 90mm connecting rods soon.