Polini 221cc cylinder

Update: Malossi MHR 221ccm cylinder for Vespa PX 200 available Malossi MHR 221ccm cylinder

As with the new one Malossi Sport and MHR cylinders , we also dedicate ourselves to the details of the Polini 221cc cylinder for 60mm stroke crankshafts. We had already measured timing & co for the Polini 221 cylinder for the Vespa here: Polini 221ccm 60mm long stroke.

compression

The one included in the cylinder kit cylinder head is also with the current Polini 210cc used. Polini regulates the adjustment of the compaction simply by changing the pinch edge.

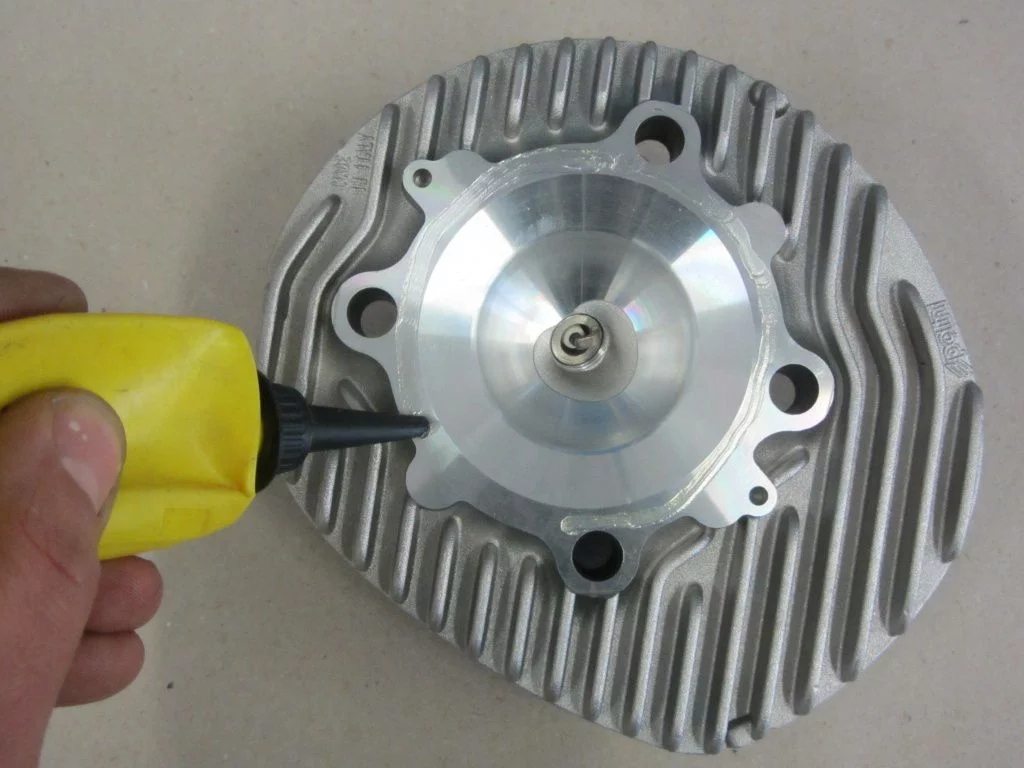

So let's grab the head and give it a suitable one Long thread spark plug and simply apply grease as a seal for our plexiglass instrument.

With the Plexiglas plate in place, we fill the cylinder head with the burette in order to determine the exact cylinder head volume.

The meniscus remains in our burette at 25ml. The volume of the combustion chamber in the cylinder head is therefore 25ccm.

To get the entire combustion chamber volume (Vc), we still need the volume of the domed piston crown. With a defined piston backing, in our case 6mm, we first calculate the volume of this “cylinder”.

6,85 x 6,85 x 0,785 x 0,6 = 22,1ccm so is the volume.

Also sealed with grease and filled with lamp oil in a playful delicate rose, the burette reveals a value of 14,6ccm. So 22,1 - 14,6 = 7,5ccm for the Volume of the piston crown.

The last ingredient is missing Volume of the pinch edge. Measured directly on the living object, i.e. directly on the engine, this is 2,2mm, which in turn has a volume of 8,1ccm requirements.

Combustion chamber volume

So we come to a total combustion chamber volume of:

Cylinder head 25ccm + pinch edge 8,1ccm - piston bottom 7,5ccm

= 25,6ccm

compression ratio

Does this result in a compression ratio? from

Cylinder displacement 221ccm + combustion chamber volume 25,6ccm / combustion chamber volume 25,6ccm

= 246,6ccm / 25,6ccm

? = 9,63

Polini 221ccm cylinder put to the test

Here is another example of the Polini 221 based on a customer engine.

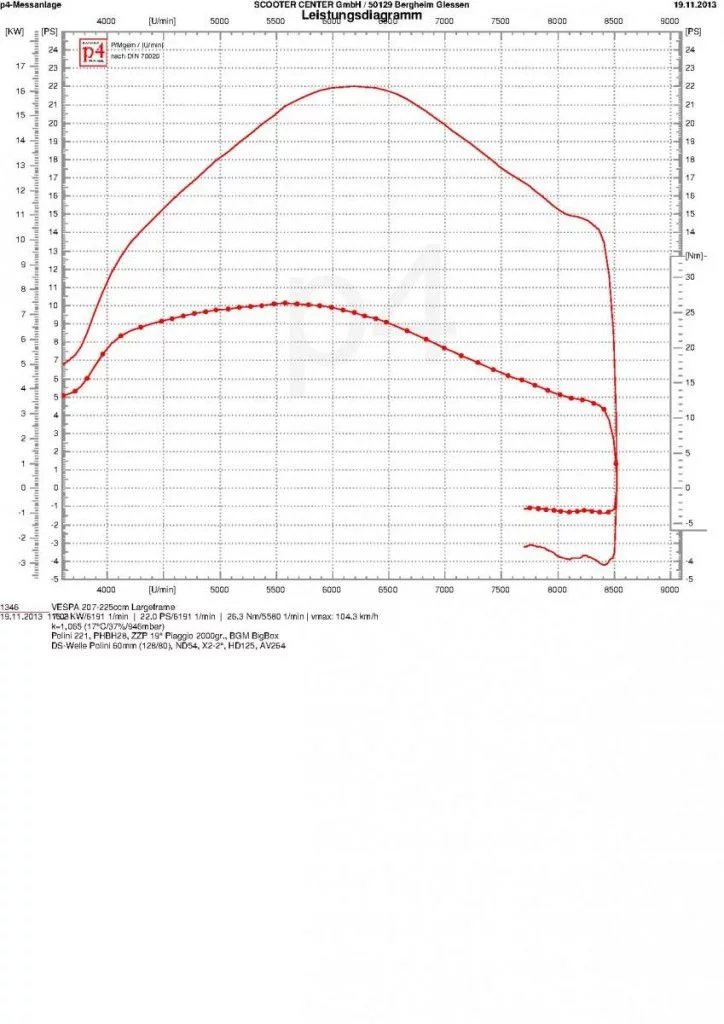

So Polini 221cc, Polini crankshaft 60mm stroke, Dellorto PHBH 28, Polini intake manifold for rotary valve and ours bgm BigBox. With the original cylinder base seal, control angles of 120 ° / 170 ° result. For more information, see the diagram below.

For a motor that is only plugged together, i.e. has not undergone any machining of the channel surfaces, 26Nm is a reasonable amount of torque. Especially when power and torque are available that early.

At 4000 rpm, 20Nm are already available, which is at least twice the value that an original PX200 reaches as a maximum.

Depending on the gearbox setting and application preferences, one can confidently longer primary can be used to achieve a solid cruising speed at low speeds on the motorway. The low-vibration running of the Polini crankshaft then contributes to the rest of the comfortable journey ...

120km / h cruising speed

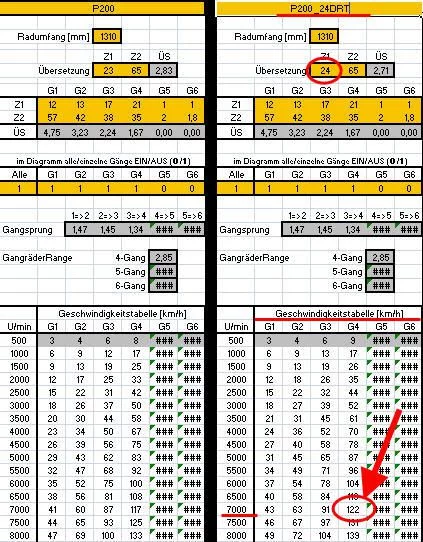

With this motor and a longer reduction ratio should permanent 120km / h to be possible. Here ** as an example, once with the original gearbox and once with our bgm Superstrong clutch and DRT pinion extended by one tooth on the original primary of the PX200 with 65 teeth.

Since there are still 7000PS at 20rpm, it is possible to crack the often cited 120Km / h mark.

** The gear calculator "GearCalc" was kindly made available to us by GSF member Motorhead. Thanks very much!