Posts

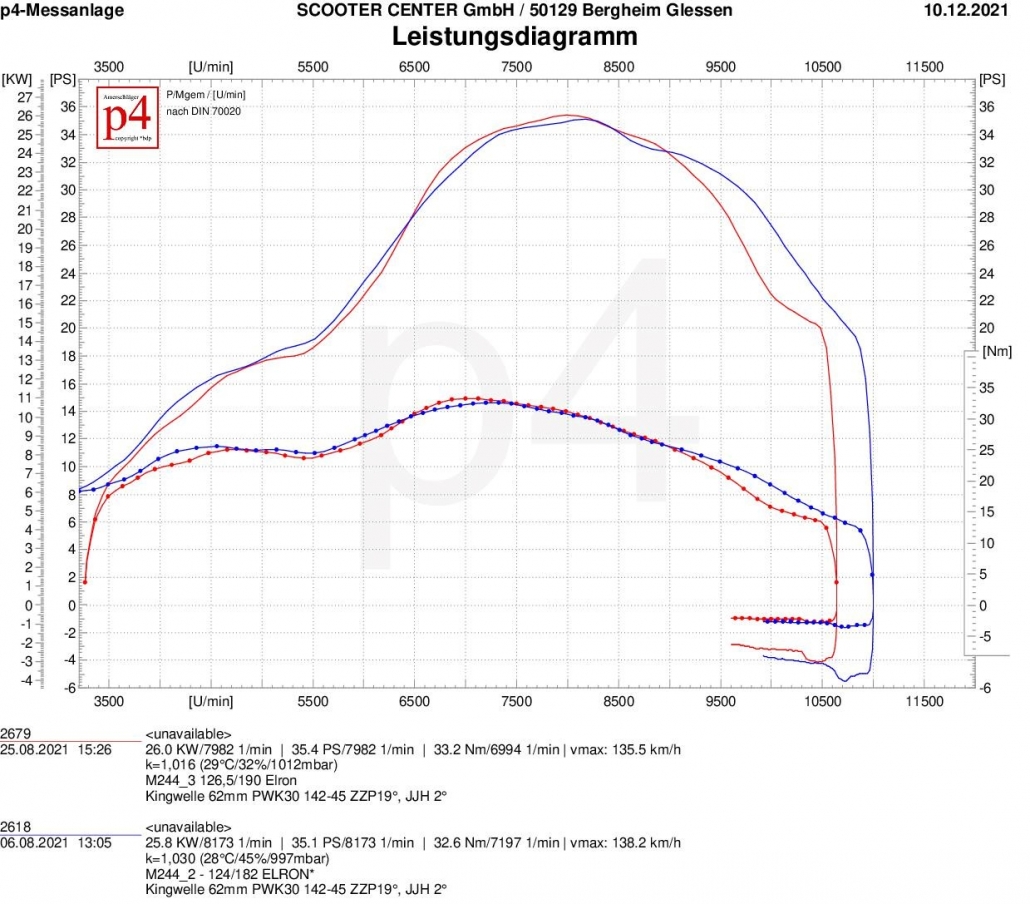

In the fourth part of our little blog series we make the following changes to our test engine:

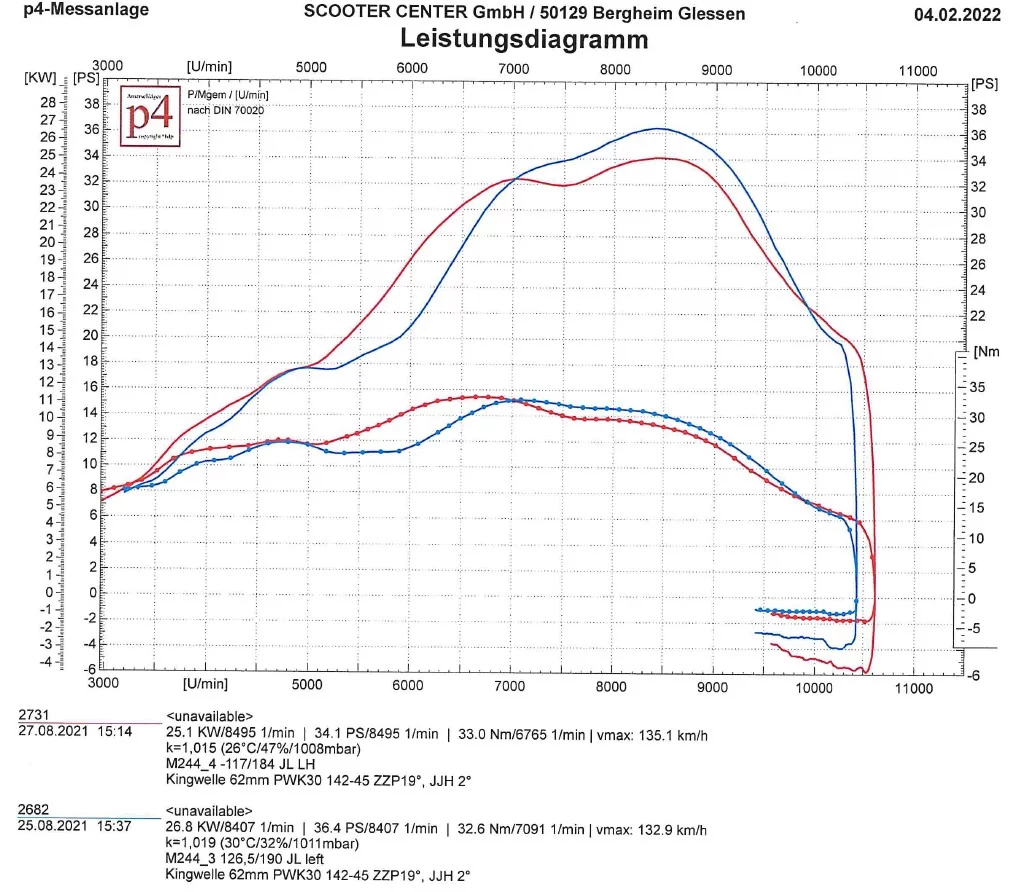

The cylinder is attached at the foot with two 1mm Spacers increased by a further 2mm compared to level 0.5. This changes the steering angle of the transfer channels from 124° to 126°. The outlet is adjusted to a control angle of 190° by milling. To do this, the outlet in the cylinder was raised by 1.8mm. The outlet width remains unchanged at 57%.

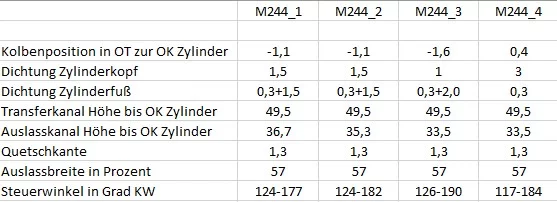

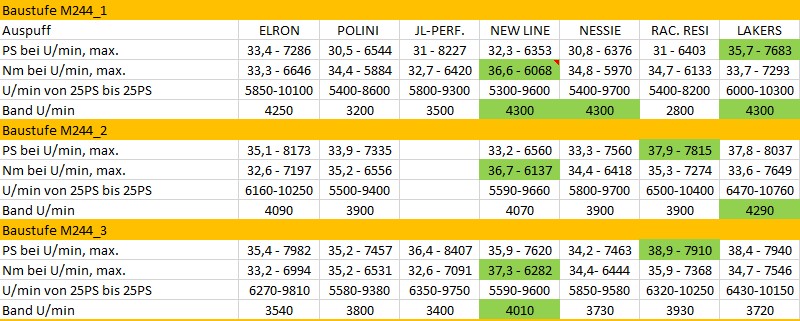

The first attempts are made with the Elron

A little more nervous exhaust systems would show a clear shift in the direction of performance with the changes made, but the Elron is almost unimpressed by the specifications of the cylinder and retains control over the characteristics of the engine. A slight increase in the maximum values after the decimal point only indicates that the Elron has noticed that the cylinder is sending a clearer signal through the exhaust. However, the maximum torque remains at the same level as in the first construction stage.

The available speed range is reduced by 500 rpm to 3540 rpm.

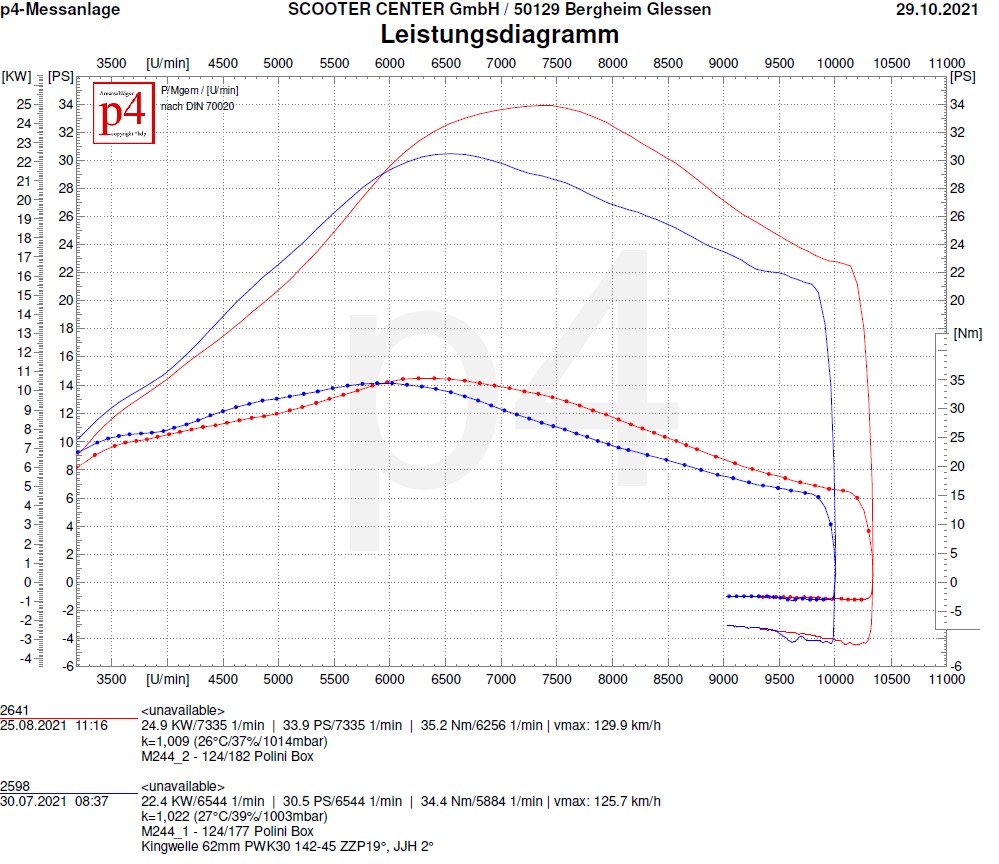

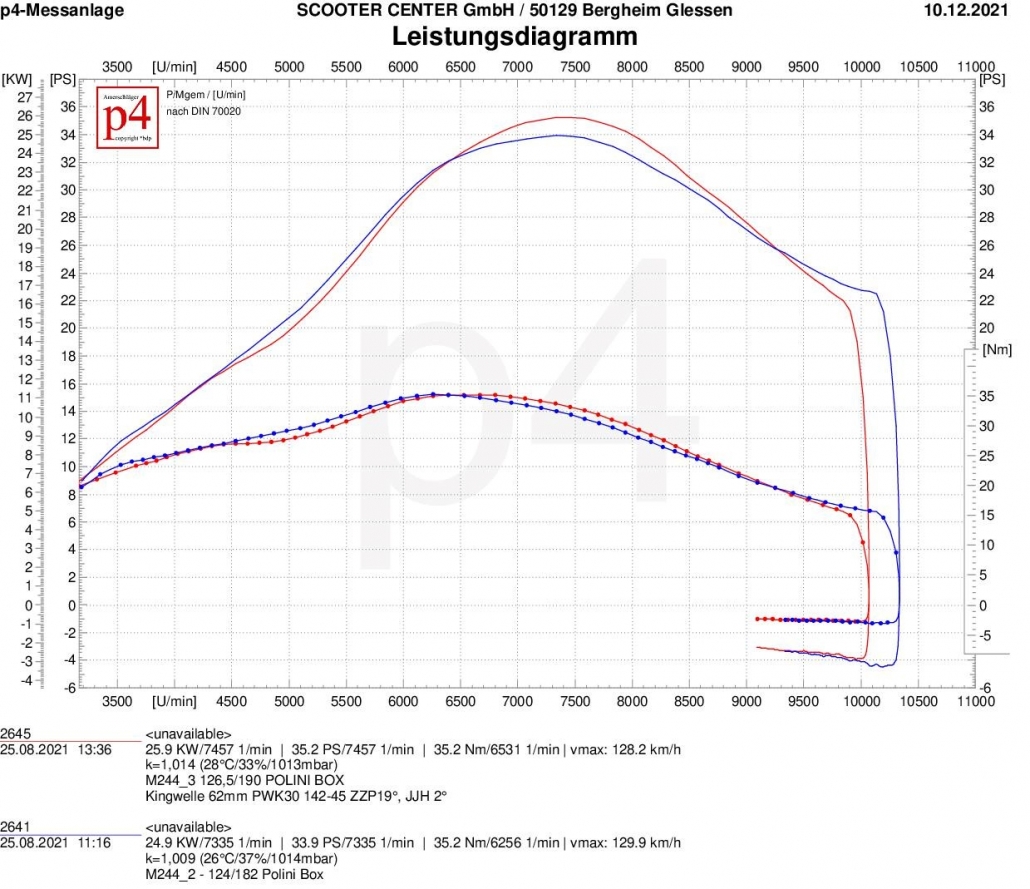

Polini box

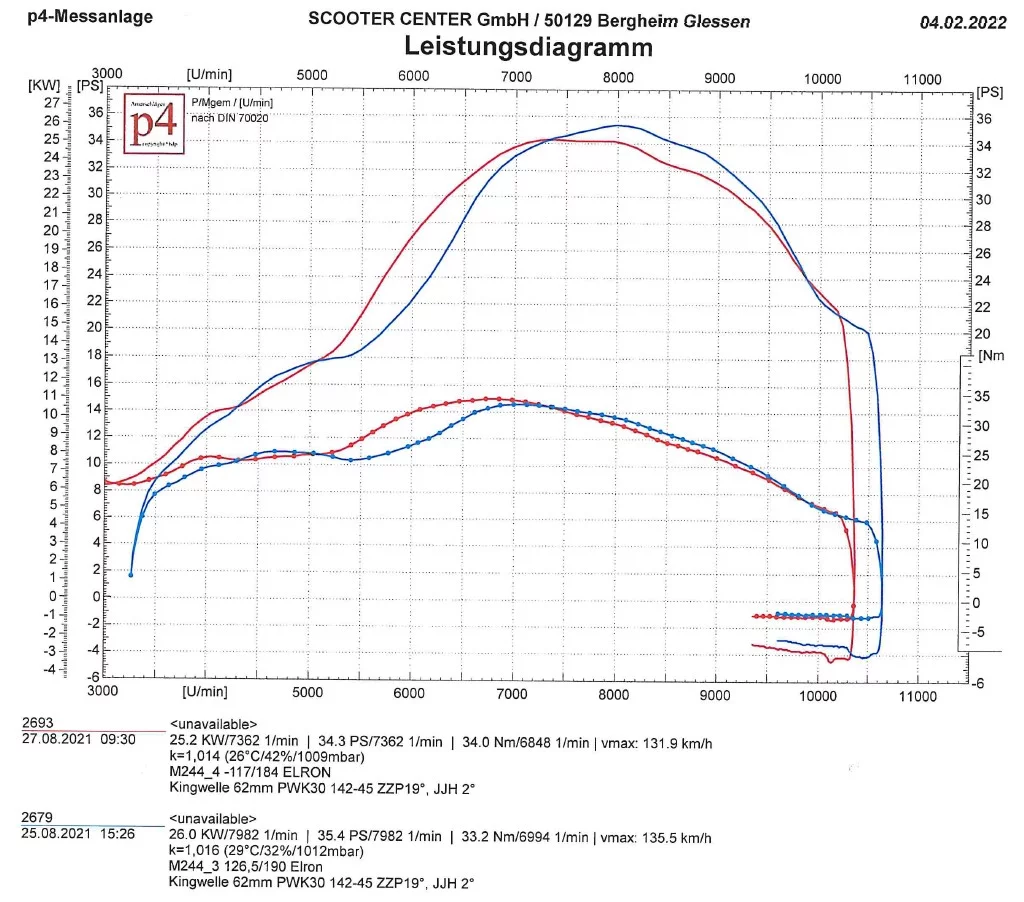

As a box exhaust, the Polini exhaust system reacts more as expected. Similar to the Elron, the can from Italy only shows small reactions. The lower effective compression makes the curve dip a bit in the rise between 4000 rpm and 6200 rpm. The system converts the slightly increased time cross-section at the outlet window with a gain of just over one horsepower at peak.

The maximum torque remains the same at 35.2Nm and is only shifted by a few hundred revolutions in the direction of higher speeds.

With a bandwidth of 3800 revolutions, the Polini system is slightly behind stage 2, but this test shows that the box does not necessarily prefer the very small steering angle. In a direct comparison to stage 1, the bandwidth and maximum values have increased significantly.

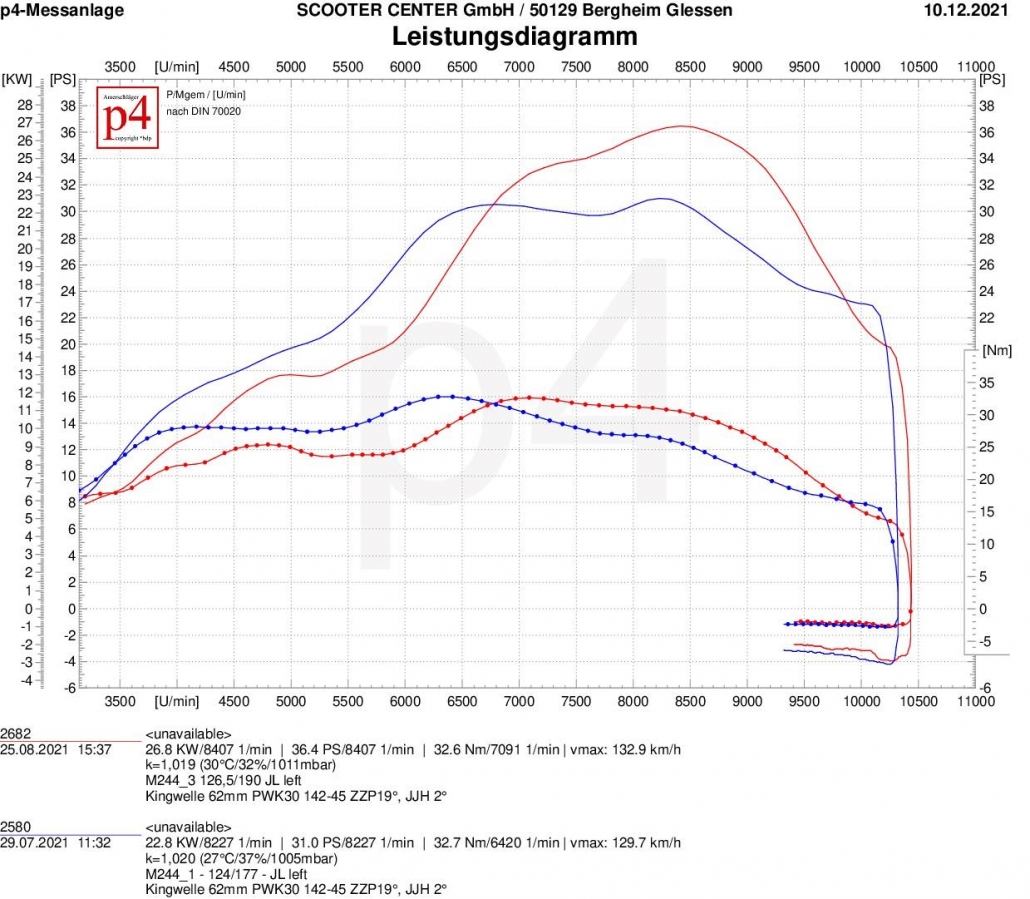

JL left hand / JL performance

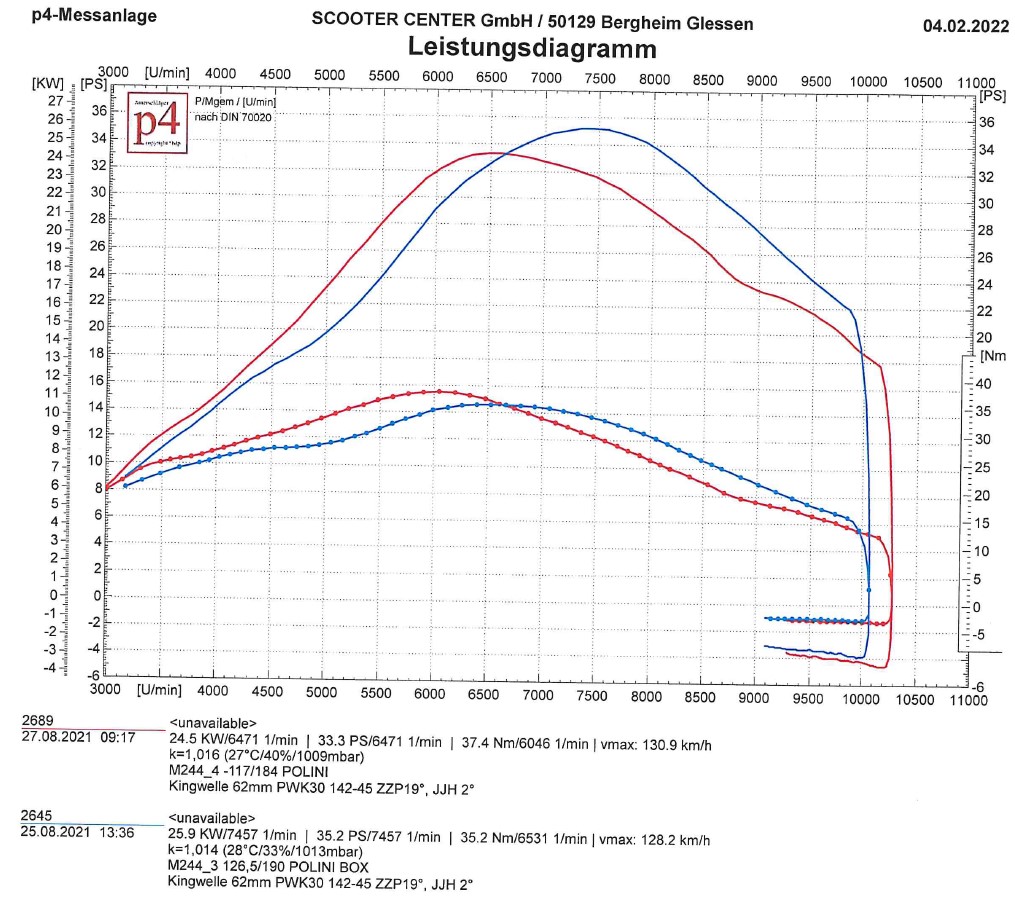

Our test subject had a short break in the previous construction stage due to appointments away from home; but now plays again in the third construction stage. So here is the comparison between levels 1 and 2.

This also shows how clearly an exhaust can behave when it is operated from other steering angles. The JL, which is considered good-natured, turns out to be a very approachable partner in the search for performance.

At the top, the JL provides almost five and a half more horses and climbs over the 36PS line in the graph. The torque remains at 32.6Nm at the same level as in the first attempt. However, the torque extends over a much wider range - beyond 7000rpm. The performance peak is reached with 36.4PS at 8400rpm. The JL falls below the 25 HP line considered in the bandwidth only beyond 9600 rpm and can therefore not be described as a lazy speed. In general, the graph shifts significantly in the direction of higher speeds. With a bandwidth of only 3400 revolutions, the JL even lags behind the Elron and brings up the rear in terms of bandwidth in this construction stage.

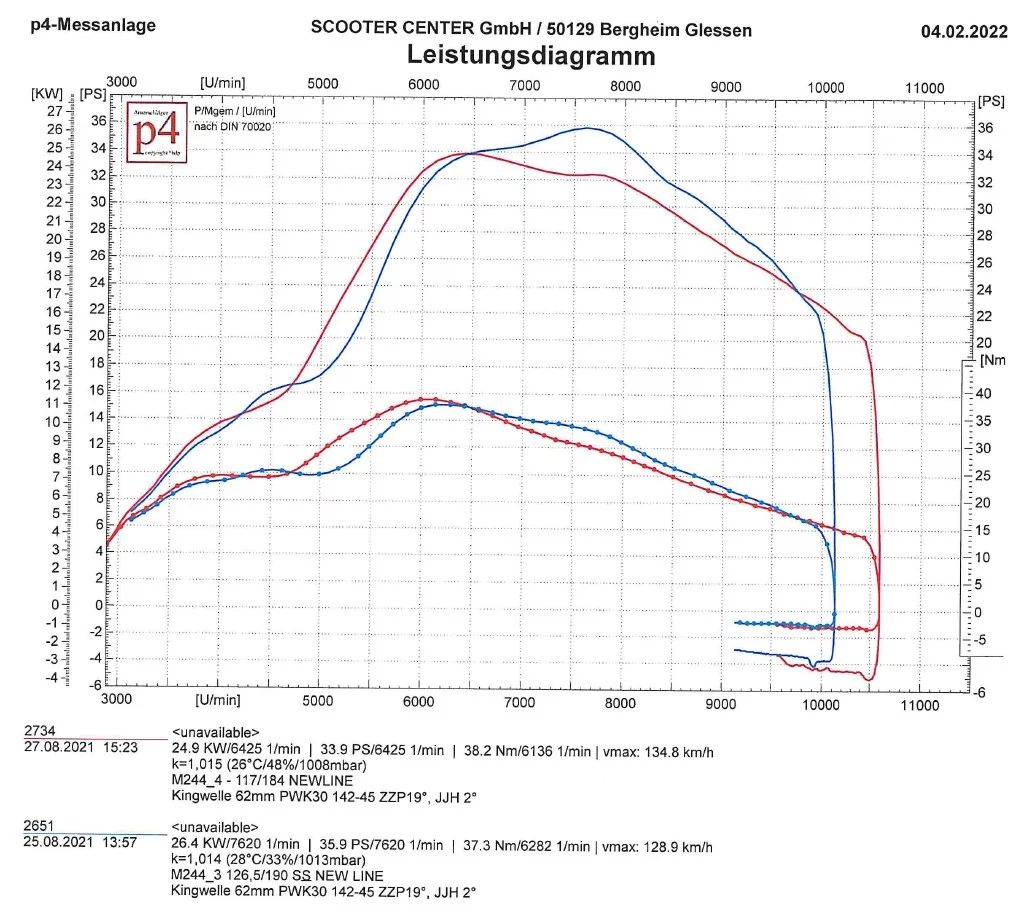

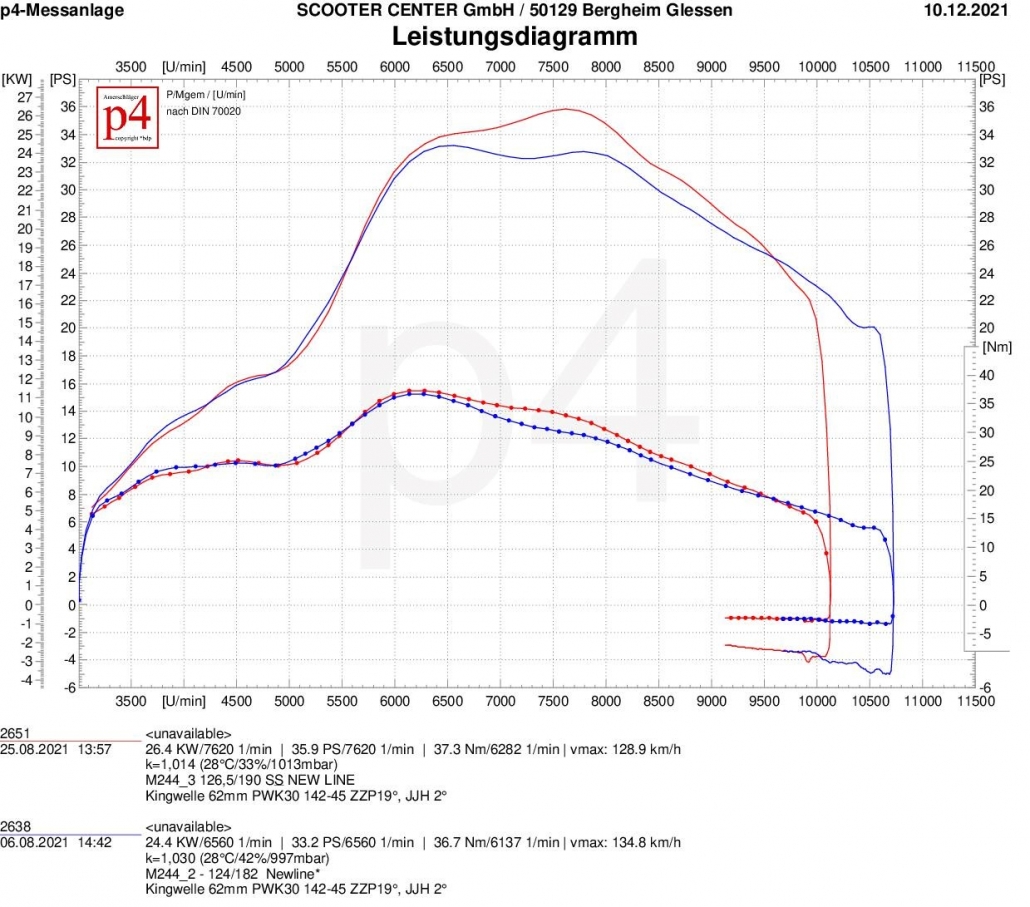

Scooter and Service Newline

The edgy powerhouse from the north feels really comfortable in this expansion stage and takes two best values with it.

There are no notable changes in the rise in the newline, but it does quite a bit due to the larger advance angle in the engine speed range. With 37.3Nm, it takes the top position in terms of torque in the third construction stage. The available speed range is narrower compared to the previous tests, but here too the Newline achieves a range of 4000 revolutions. With these values, considerations germinate after a longer primary with 24-60 ...

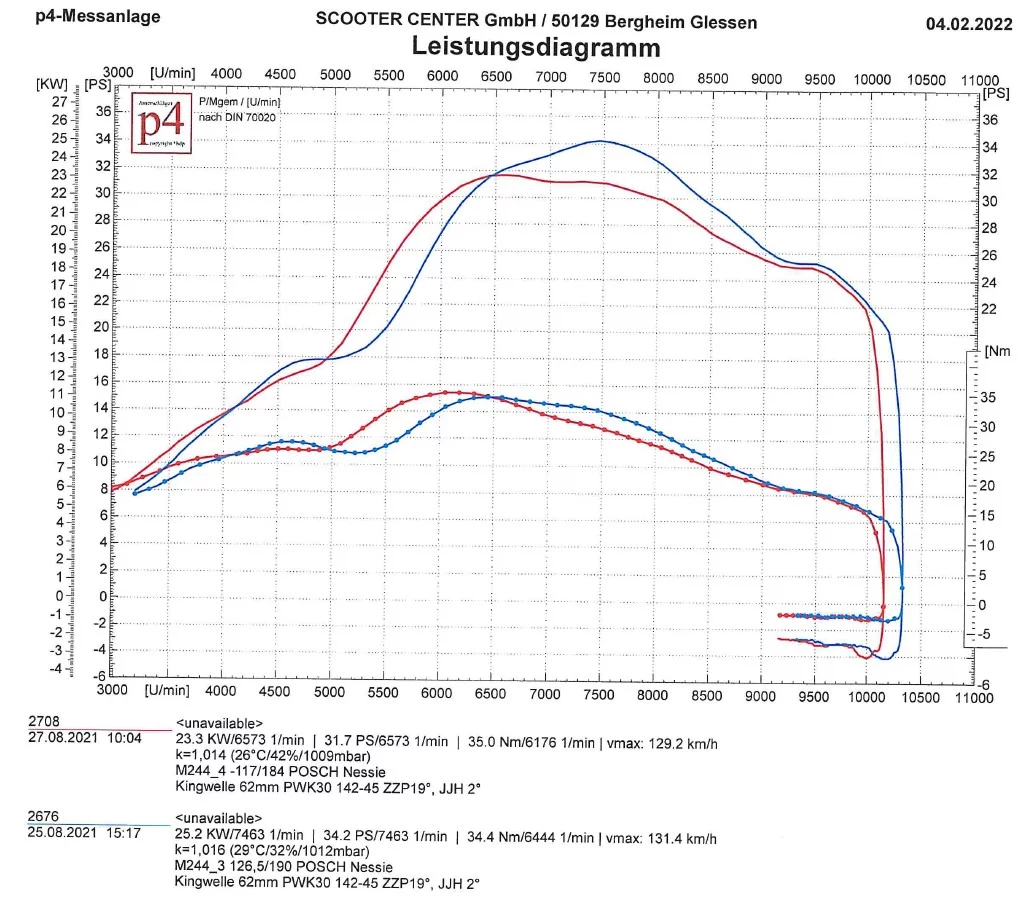

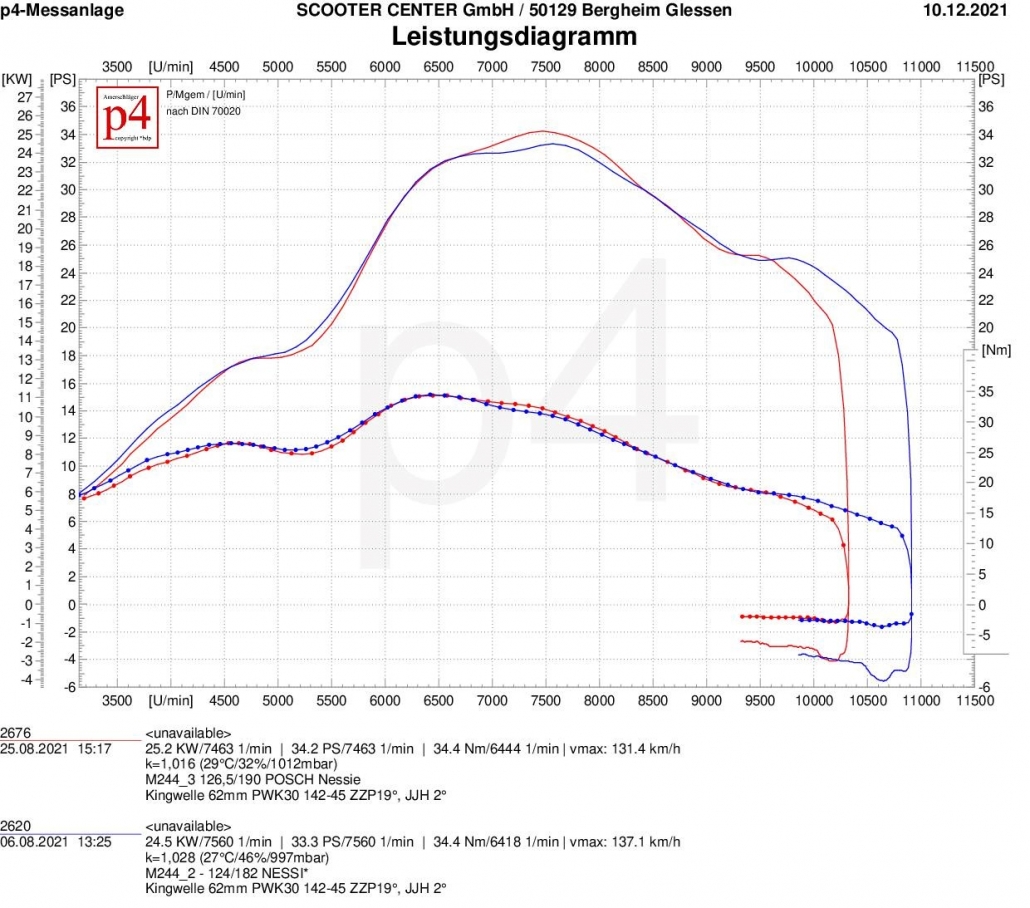

Nessie

Like the Elron, the sea monster from Posch Performance is not quite sure what to do with the changed control angles. Maximum torque remains the same and peak power increases by one horsepower. While the Nessie was still way ahead in level 1 with 4300 rpm in terms of bandwidth, the available speed range in level three is a bit on the dip station and is in the upper midfield with 3700 rpm.

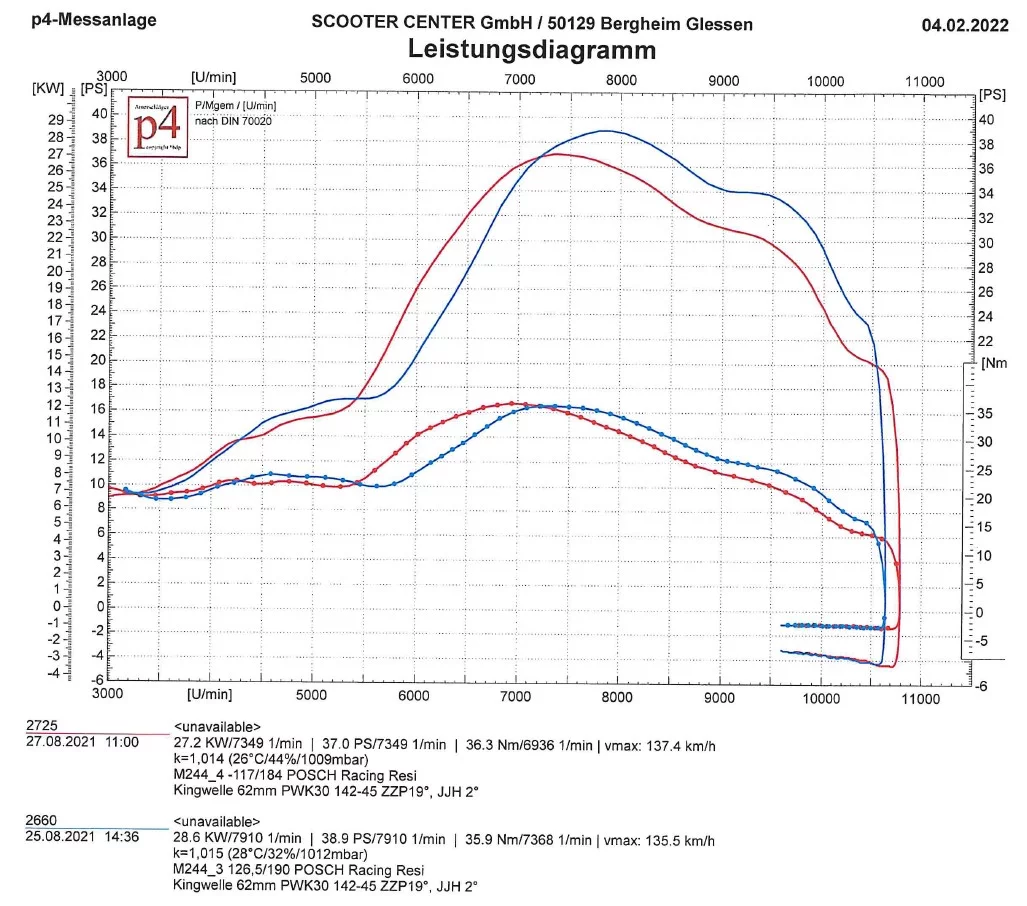

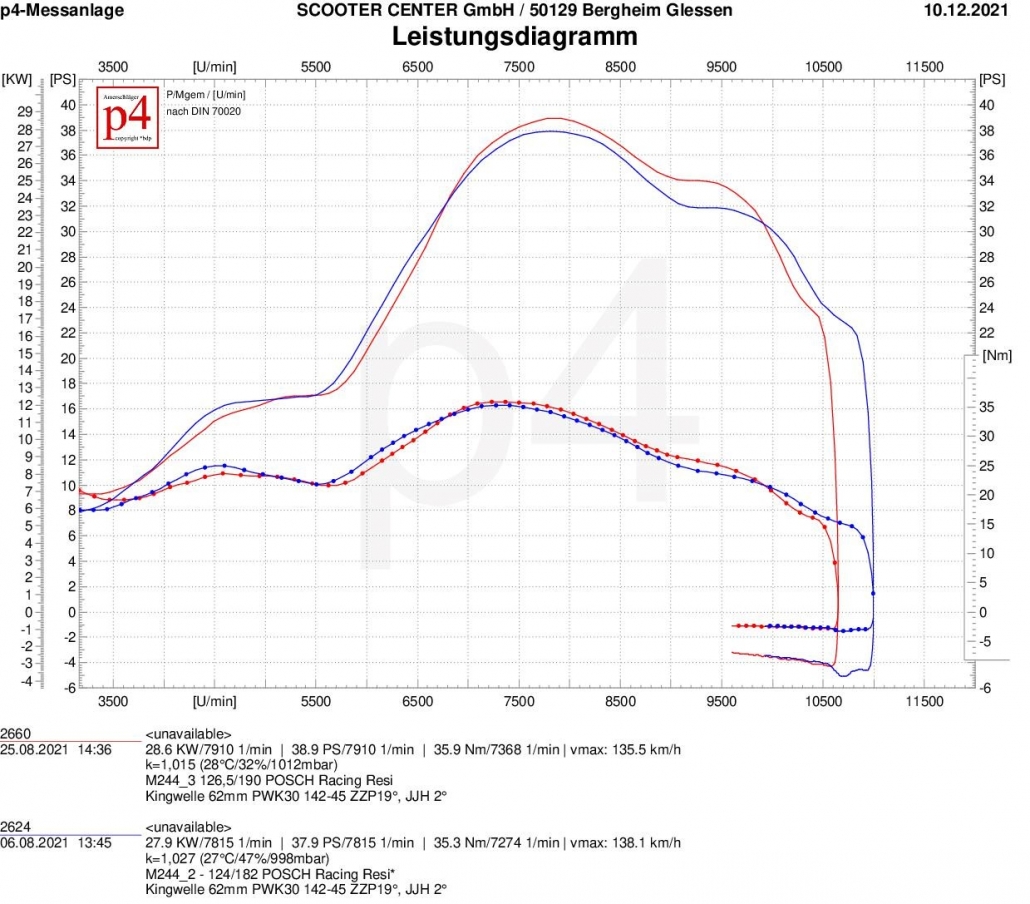

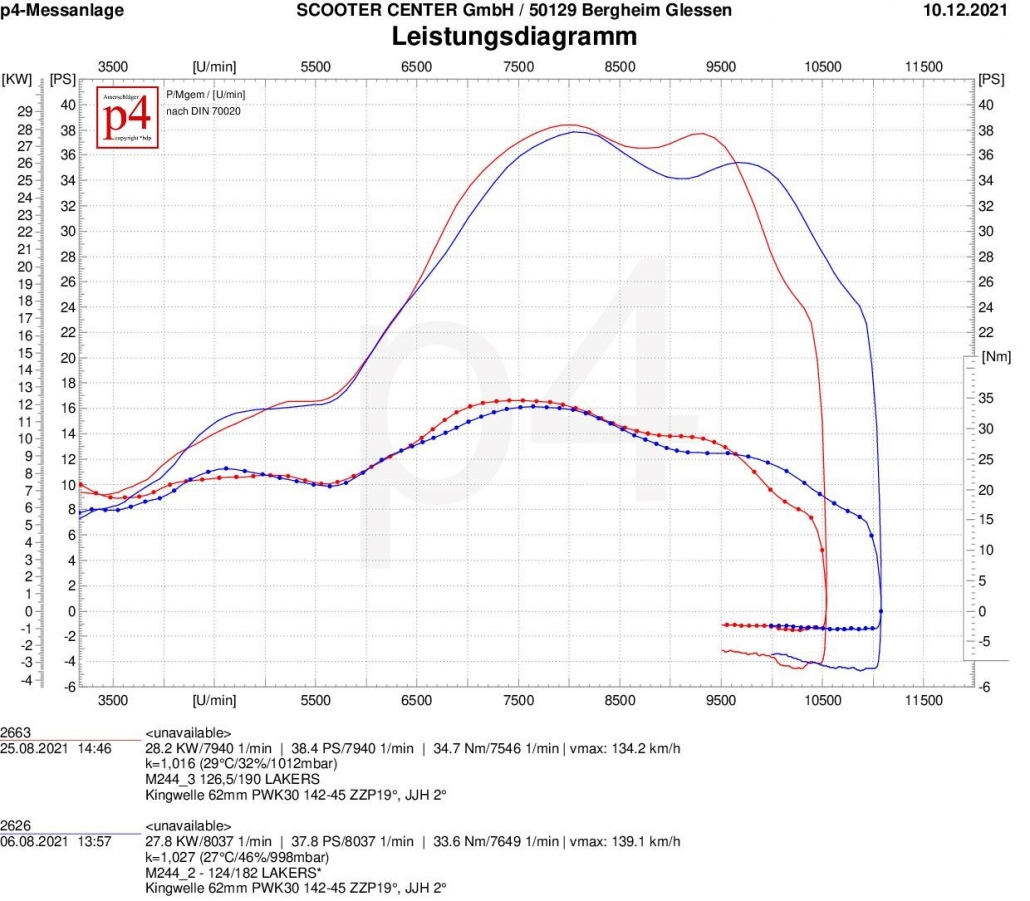

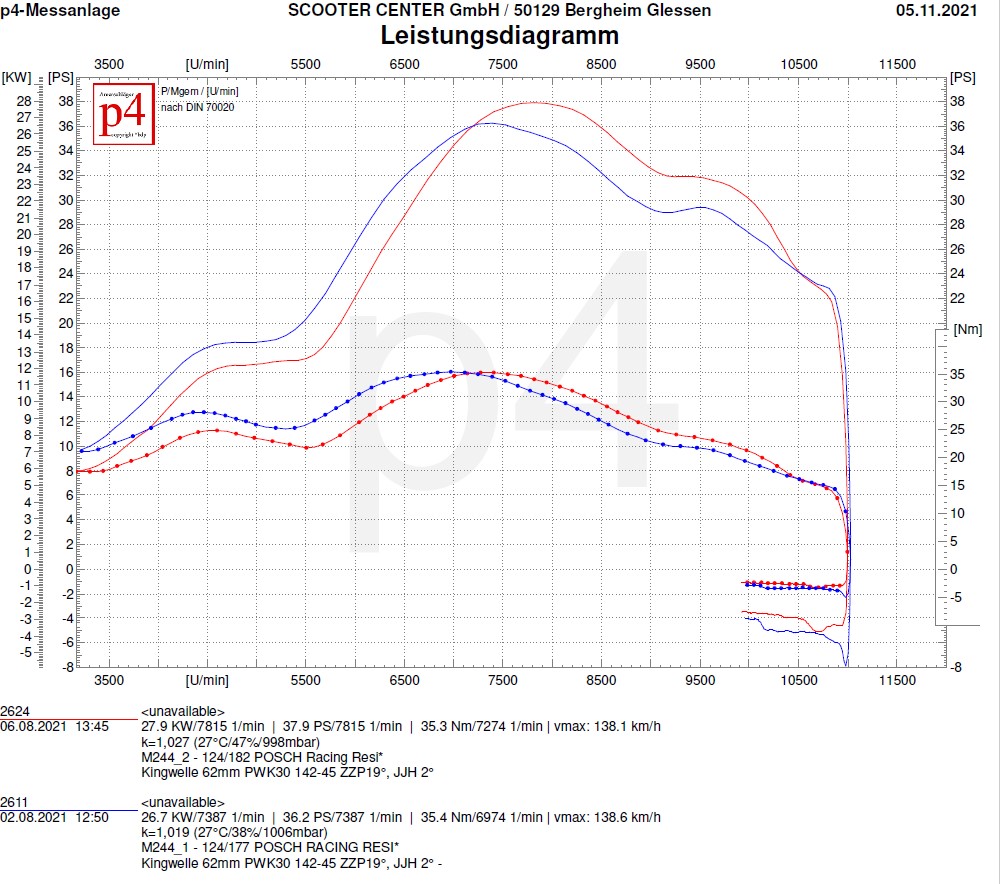

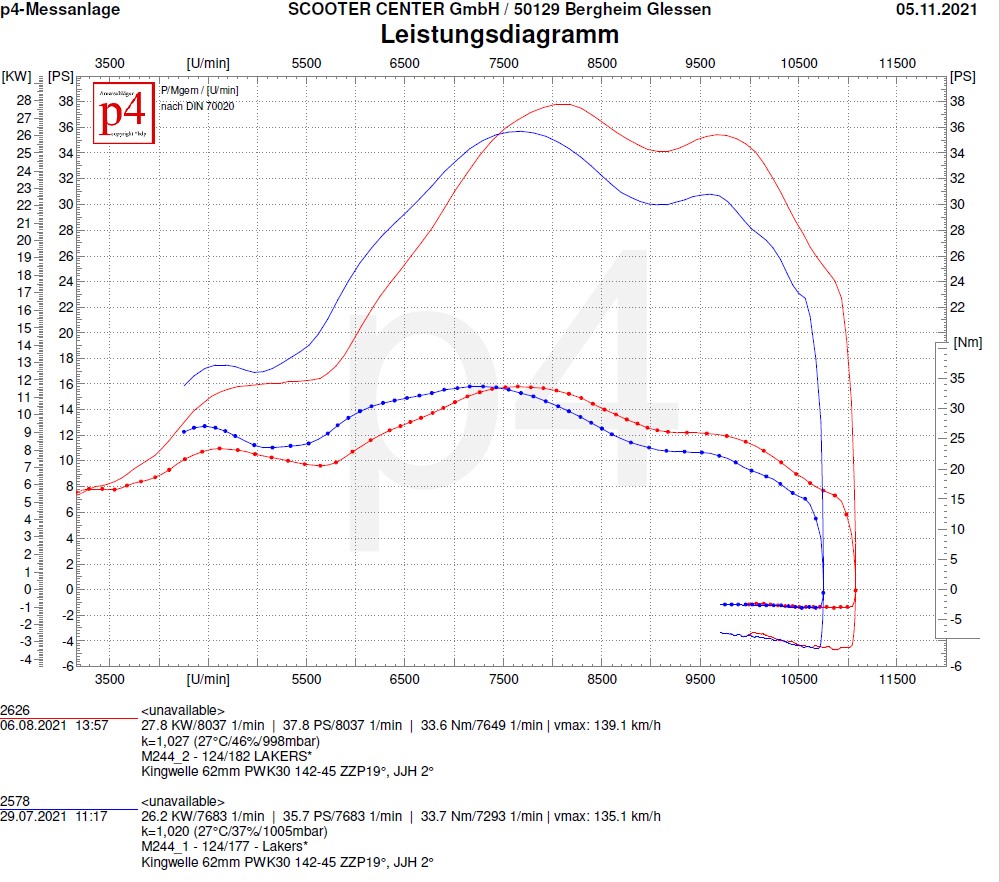

Racing Resi

The Racing Resi taste the changes better. Rather devoted to the higher control angles, the Resi develops one more horsepower at the top and adds torque, which hardly affects the bandwidth on the 25hp line. In absolute terms, the Resi holds the position of the highest peak power with 38.9 hp in this level. We are slowly approaching the 40hp mark with the expansion stages.

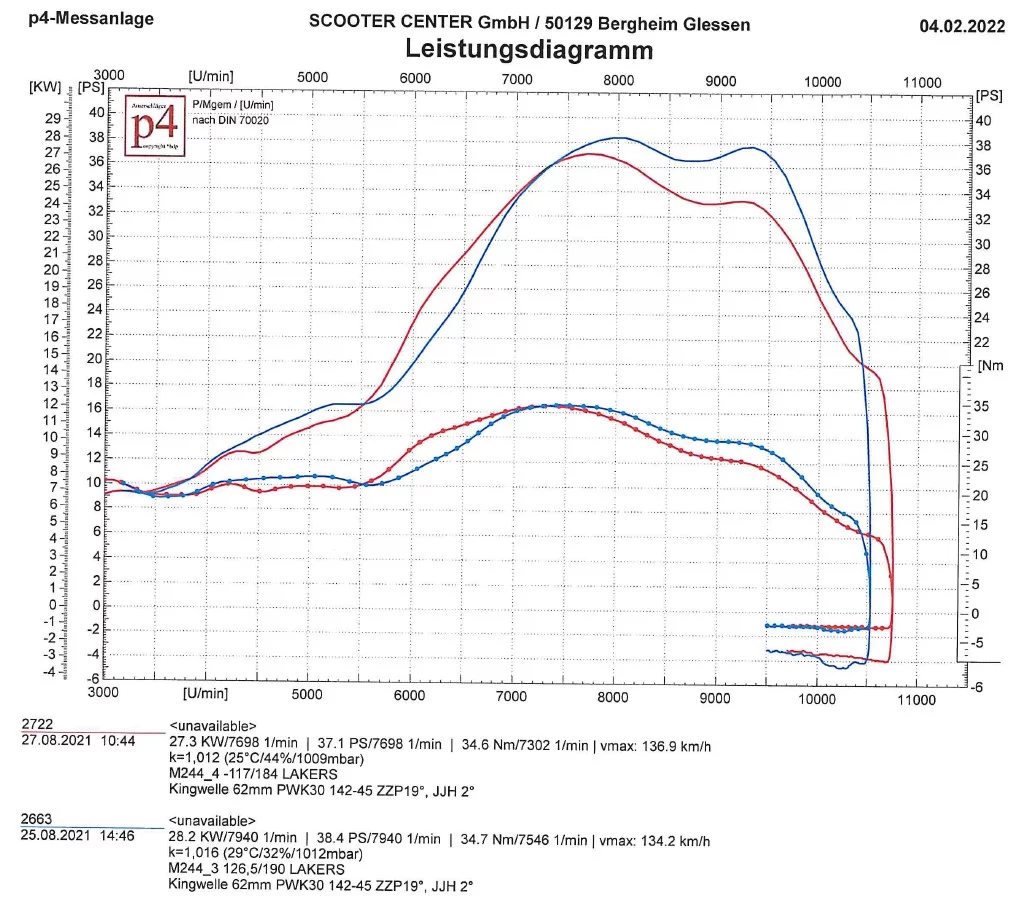

Lakers

With 126° to 190°, the Lakers are not yet playing in their comfort zone. Although it also clearly converts the changed control angles into performance. With 38.4 hp at the top, it is only just behind the Resi. With a speed range of 3700 rpm, which already extends to 10.100 rpm, the Lakers shows where the journey can go with suitable peripherals.

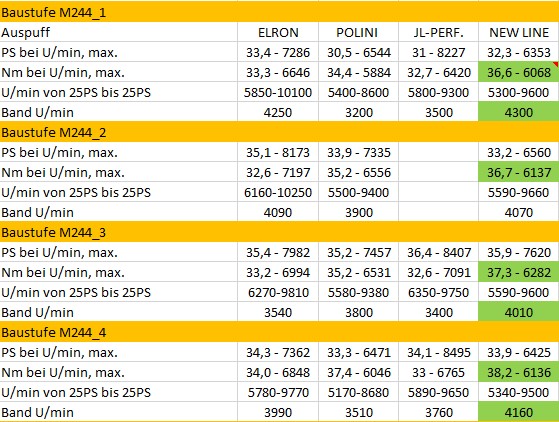

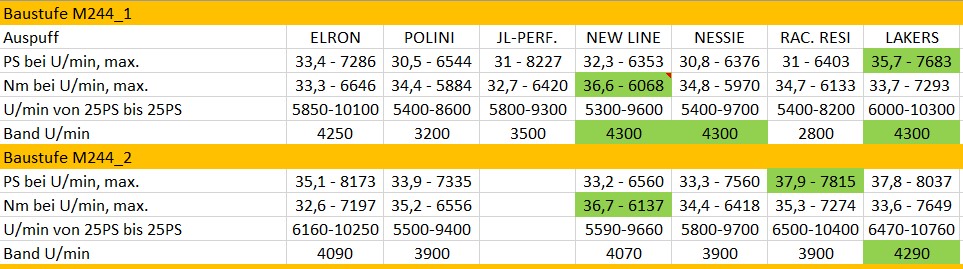

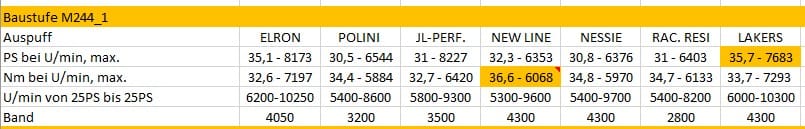

Here is an overview of the results. Best values are highlighted in green.

Quattrini M244 king shaft - the super tourer in the second expansion stage "outlet" M244_2

M244 - part 3

Im second part this Series we simply adapted the cylinder and the engine housing to each other and put the cylinder on the engine without further processing "Plug & Play".

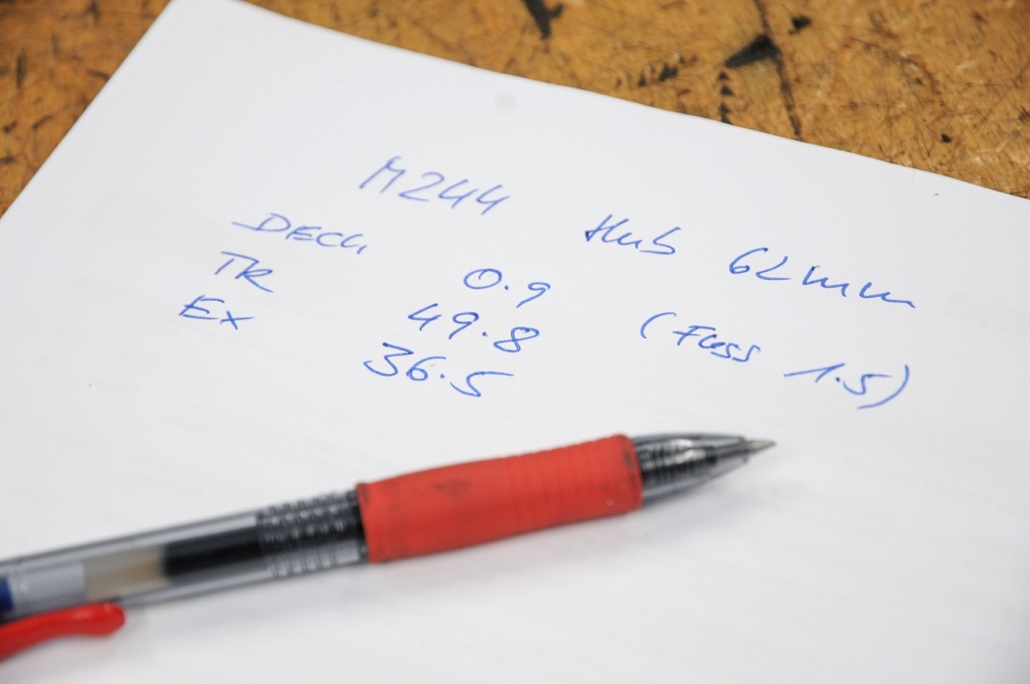

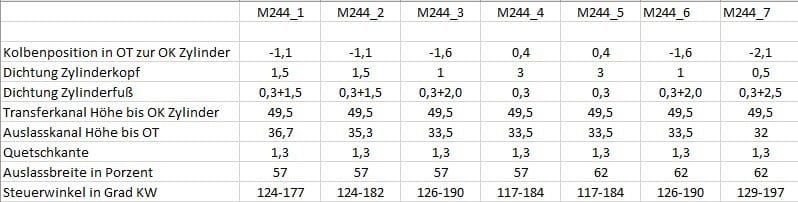

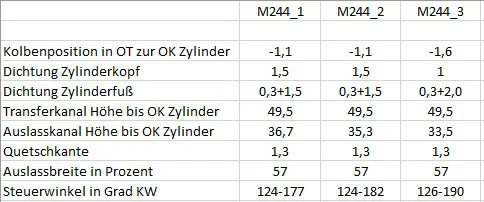

This resulted in very moderate control angles:

- with 124 ° transfer angle

- and 177 ° outlet angle

Some exhaust systems get along well with these short steering angles and thus provide quite astonishing performance.

On the other hand, the exhaust systems, which are trimmed more for performance, require larger steering angles.

In the course of the test series, the character of the performance curve of one or the other exhaust system will change.

Therefore we remove some material from the M244 in the exhaust duct and set the upper edge of the exhaust to 182 °. The outlet width remains unaffected and remains at a chord dimension of around 57%.

As a spacer, we use 1.5 mm on the cylinder head and the cylinder base plus a 0.3 mm seal on the cylinder base. This means that the control angles remain at 124 °:

- 124 ° transfer angle

- 182 ° outlet angle

- 57% tendon size

Cylinder cooling hood for the long M244 Quattrini

In the meantime we have also received a matching cylinder cooling hood from GRP specialist BSK. You can find the blog here -> QUATTRINI GRP CYLINDER HOOD

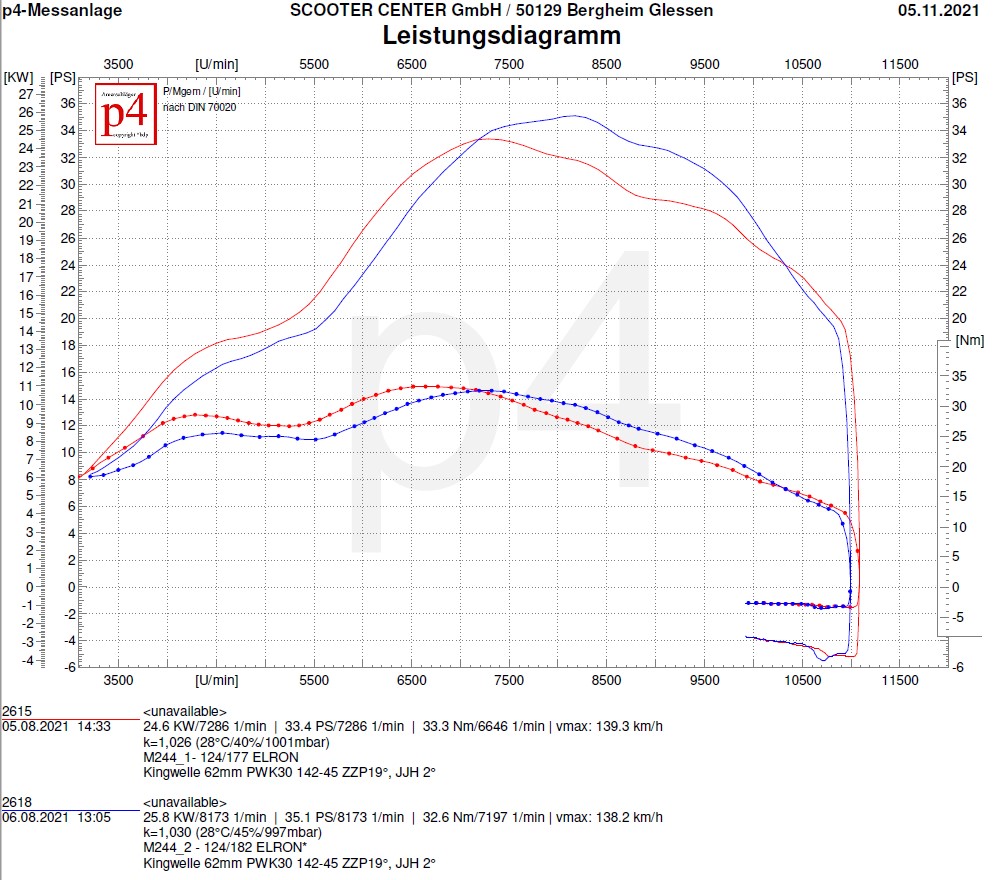

TEST ELRON

The Elron uses the larger steering angle rather cautiously. With a 1,7 HP increase in peak performance, a slight loss in torque and a little less band due to the 300 rpm later entry, the exhaust shows that it takes note of this requirement but does not yet represent the right playing field for the concept . However, the Elron takes this very calmly. Presumably, the exhaust will deliver a very pleasing performance curve even with significantly different control angles and thus the concept does not completely submit to the dictates of the control angle.

Test bench diagram as PDF: M244_1_2_ELRON

TEST POLINI BOX

The Polini Box reacts very clearly to the small change in the outlet and provides a lot of power. The box adds over 3PS and not quite 1 Nm. The speed range is even wider by 700 rpm, whereby the graph does not even pass the 100 hp mark at 25 rpm until 5.500 rpm later and the output lasts significantly longer up to 9.400 rpm. The control angles of 124 ° to 182 ° seem to be clearly pleasant to the Polini Box.

Test bench diagram as PDF: VGL_M244_1_2_POLINI

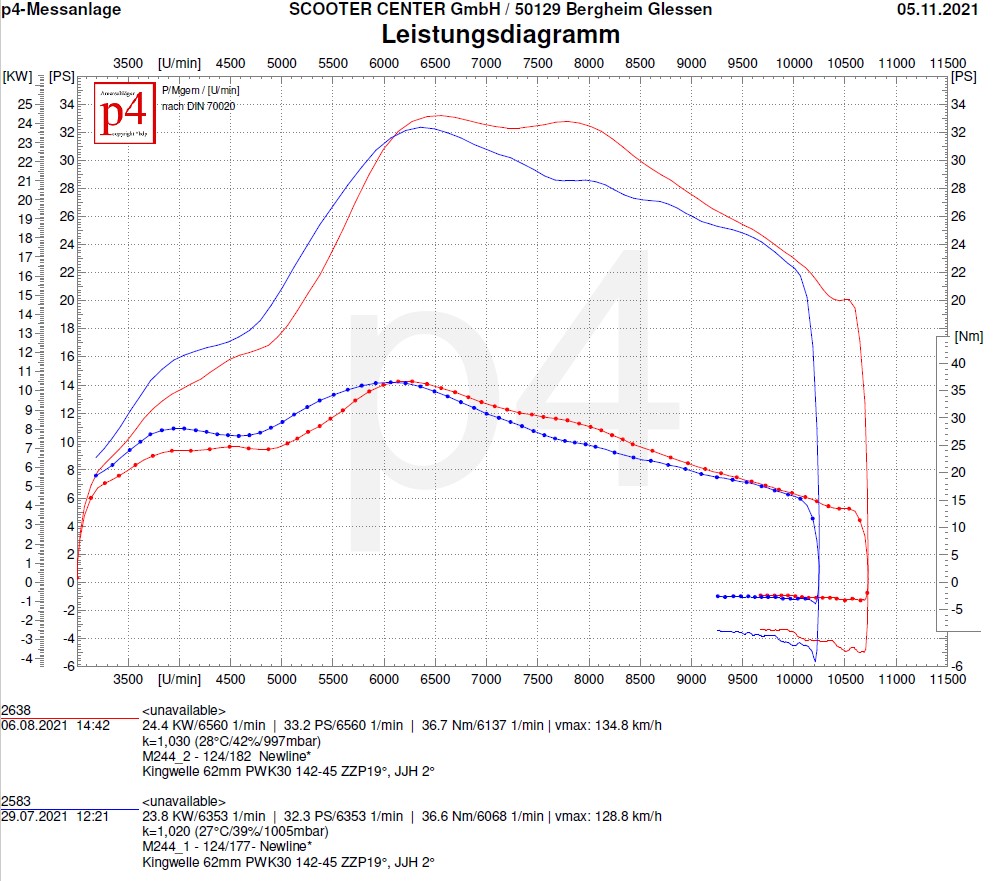

Test Scooter and Service NEWLINE

The Newline generally shows a different character in terms of power increase at small steering angles than the Elron or the Polini Box.

Similar to the Elron is the rather unimpressed behavior on the changed exhaust control angle. The peak power increases by almost one hp, the maximum torque remains almost identical and the speed range becomes somewhat narrower, as with the Elron, due to the later start of resonance. Even in the second expansion stage, the Newline retains the top position when it comes to torque with 36,7 Nm at 6.137 rpm.

Test bench diagram as PDF: M244_1_2_NEWLINE

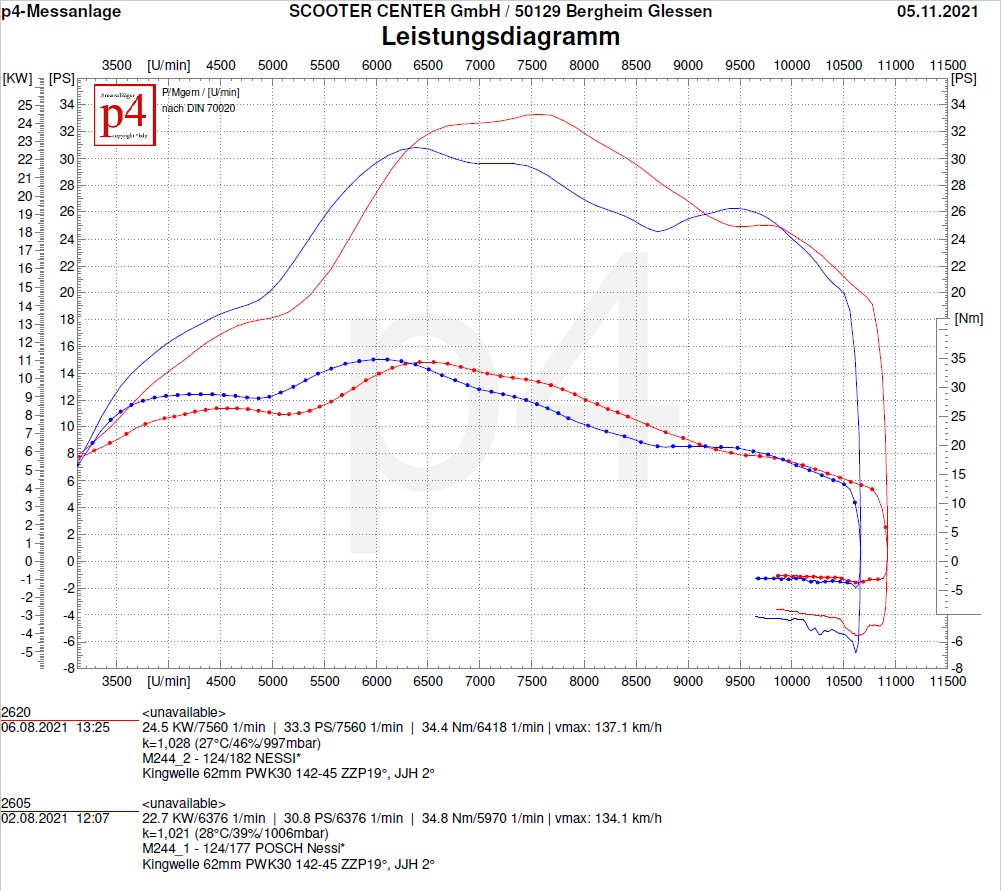

Test Posch Nessie

The Nessie, like the Newline, is intended for moderate control angles, and also shows the clear shift at the start of resonance. Viewed in absolute terms, the Nessie “only” adds 2,5 HP to the top, but in the range between 6.300 rpm and 9.000 rpm it can be clearly seen that the larger outlet angle significantly increases the performance over this range.

Test bench diagram as PDF: M244_1_2_NESSIE

Test Posch Racing Resi

The Racing Resi with its imposing, bulbous appearance already gives the impression of performance and the greed for steering angles. Therefore, the slightly increased outlet angle is not enough to achieve absolute top performance. Here, too, the start of the response is much later. At its peak, the Resi increases by 1,7 HP and this can use the slightly increased exhaust control angle between 7.300 rpm and 10.000 rpm to increase power and torque.

Test bench diagram as PDF: M244_1_2_RAC_RESI

Kingwelle Lakers test

The robust racing exhaust from Lake Constance has already shown on the plugged-in version of the M244 that it is also a good all-rounder. As with all other tested resonance systems, the speed range also shifts in the direction of higher speed, but without the bandwidth being affected. With a band of almost 4.300 rpm, it provides the largest bandwidth in this expansion stage. With 37,8 PS at its peak, the Lakers, at least in this expansion stage, has to admit defeat to the Resi with 37,9 PS - but we are only just warming up on the subject of the steering angle.

Test bench diagram as PDF: M244_1_2 LAKERS

The results of the test bench runs, expansion stage 1_2

Here again the results in tabular form. The best values are highlighted in green for each construction stage

Part 4 is already in progress ...

Quattrini M244 king shaft - the super tourer in the first expansion stage "Plug & Play" M244_1

This is part 2 of this Quattrini M244 - Series. In this first construction stage, M244_1, we have the M244 without any further changes, only with spacers on the cylinder head and the cylinder base our engine eingerichtet.

We have entered the resulting control angles in the list for the test plan.

In terms of design, this setup is in the middle of the range of expansion stages.

TEST POLINI BOX

First we send the all-purpose weapon from Polini into the race.

Test bench diagram POLINI BOX exhaust on Quattrini as PDF: M244_1_POLINI

The result is quite clear. Already at 4000rpm there are 15 HP and 26Nm on the rear wheel.

The maximum values are 30.5PS at 6500rpm and 34.4Nm at 5900rpm.

Even at 9500rpm there are still 22PS on the rear wheel. This constellation already calls for a longer primary translation.

TEST FALKR ELRON

The next test subject comes from FalkR and listen to the name Elron's.

Test bench diagram FALKR ELRON exhaust on Quattrini as PDF: M244_1_ELRON

With regard to the maximum values, the Elron ranks as real resonance exhaust already above the Polini Box. But the tide is turning only beyond the 6500rpm in favor of the Elron. In the range before 6500 rpm, the Polini Box has the lead here. After passing the 6500rpm mark, the Elron gains significantly and is above the Polini Box up to the end of revs beyond the 10500rpm.

TEST JL PERFORMANCE

Another old friend is that JL performance.

Test bench diagram JL-PERFORMANCE exhaust on Quattrini as PDF: M244_1_JL_LH

The somewhat outdated concept of the JL still delivers reliable values today. The JL does not cope with the first stage of the engine quite as well as the Elron. With 31PS at 8200rpm, that's something like suffering at a high level. The rather gentle entry and a good performance of 16PS at 4000rpm make the JL a very drivable exhaust with a good start in Reso optics.

TEST NEWLINE SCOOTER & SERVICE

The Newline exhaust from Scooter & Service is with us in Scooter Center Shop .

Test bench diagram NEWLINE exhaust on Quattrini as PDF: M244_1_NEW_LINE

The new line from Scooters and Service from Hamburg already delivers its maximum power of 6300PS at 32rpm. Even if the playing field doesn't quite fit the Newline, which would like to see a little more steering angle, the manual work from Hamburg delivers a remarkable 6000Nm already at 36rpm. The torque beast in this expansion stage

TEST POSCH PERFORMANCE NESSIE

As the first representative of the "Performance" department, we let Nessie from Posch Performance work on the M244.

Test bench diagram NESSIE - POSCH exhaust on Quattrini as PDF: M244_1_POSCH_NESSIE

Until just before 6500rpm, the world is pretty fine for the Nessie. Then the curve takes a course that suggests that the Nessie would like to see significantly more outlet angles.

Nevertheless, the Nessie with 34.8Nm at approx. 6000 rpm can be counted among the clearly high-torque systems.

TEST POSCH PERFORMANCE RACING RESI

Of course we also tested the Racing Resi from Posch Performance.

Test bench diagram RACING RESI- POSCH exhaust on Quattrini as PDF: M244_1_POSCH_RAC_RESI

The Racing Resi from the same manufacturer runs very similar to the Nessie and also requires more ventilation over longer control angles. With almost 35Nm at 6100rpm, the Resi is also well ahead in the league of absolute torque animals.

TEST LAKERS KINGWAVE

The Lakers as a thoroughbred racing exhaust, stands well in the feed despite the high performance and engine speeds to be expected with the low control angles.

Test bench diagram KINGWELLE LAKERS exhaust on Quattrini as PDF: M244_1_LAKERS

With almost 36PS at 7700rpm, it is the front runner in terms of performance in this expansion stage.

In the later expansion stages, when higher control angles and a wider outlet come into play, this exhaust can probably live out much better.

Overview test run 1 Quattrini M244 exhaust systems

Quattrini cylinder M244 in the first construction stage, M244_1 "Plug & Play" without further changes only with spacers on the cylinder head and on the cylinder base on the Malossi engine and Kingshaft crankshaft adapted.

Be curious to see how the second expansion stage will continue ...

Vespa Quattrini M244 engine 252ccm - from super tourers to top racers

The story of the Quattrini cylinder

Towards the end of 2015, rumors grew that Max Quatrini launches a potent cylinder for the PX200.

The time has come at the beginning of 2016. The M232 and the big brother M244 are available on the market.

A construction that took some getting used to seemed to follow the concept, a cylinder with a maximum bore of 72mm in the M244 and without a supporting cylinder base.

Due to the design of the crankshaft by Quattrini, with a connecting rod of 126mm, which is rather long for the Vespa engines, the piston does not work so deep in the engine housing and therefore does not need a long, classic cylinder base.

Today, in 2021, the cylinder is enjoying increasing popularity due to its very high torque values and the smooth-running design thanks to the long connecting rod of the Quattrini crankshaft.

Reason enough for us to build an engine with it and play through many possible scenarios for you and see what comes out of it. We have tested exhaust systems and carburettors for you in various stages of expansion.

In the delivery note attached here for our technology department, you will find all the components that we have used for this engine and that, in our opinion, function permanently with this concept.

200 test runs on our test bench

In total, we have over 200 test runs with the Quattrini M244 Completed on our P4 test bench with various engine expansion stages. We have more than 50km measured runs documented and almost 20 liters of fuel burned.

We would like to share the experiences gained from this test with you in this blog series.

To select the parts:

The expected high torques of the M244 speak in any case for a reinforced motor housing.

The experience from many kilometers on the road with our own scooters has taught us that engines in the range from 22 to 25 HP can be implemented as "durable" in conjunction with a Piaggio engine housing.

Our M244 Quattrini cylinder but should be expanded a bit in the course of the test. This is why the choice here is a motor housing from Malossi with membrane inlet.

An Displacement of over 220ccm at erhigher engine speed, can no longer be supplied with sufficient fresh gas via a classic rotary valve on the narrow Vespa crankshaft. That's why we choose this Malossi motor housing with membrane control .

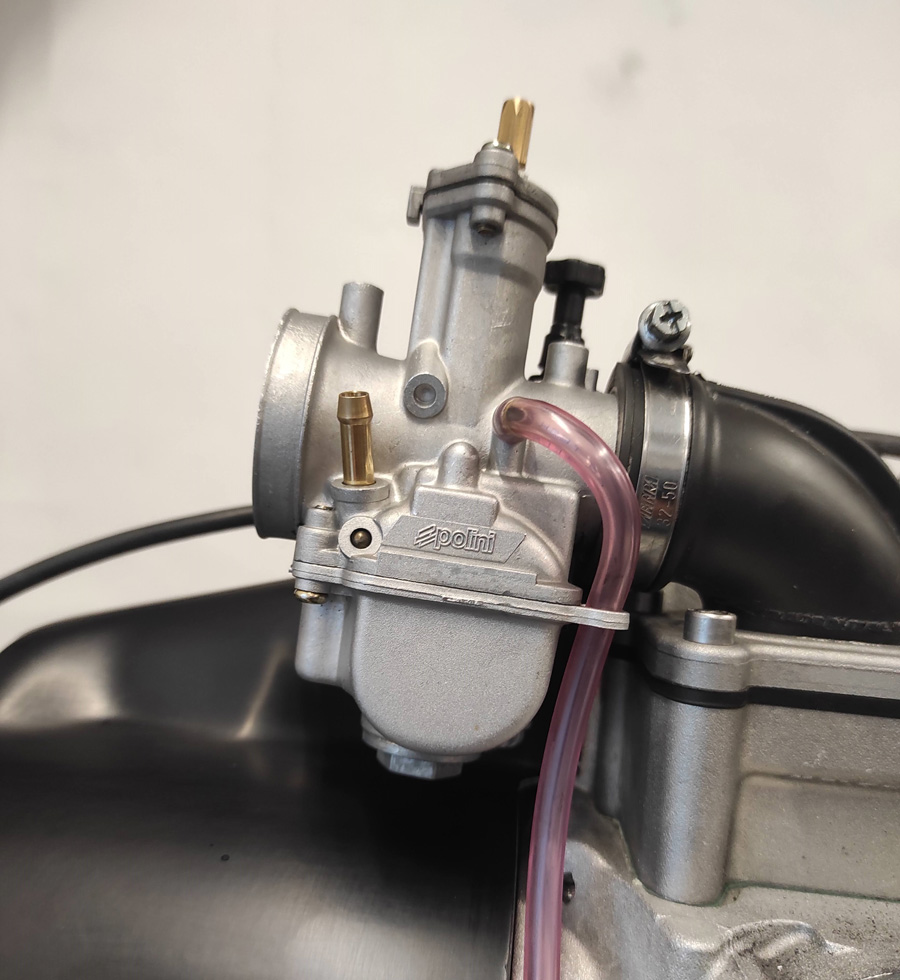

To make the fuel mixture we have one Polini 30mm carburetor used. In this experiment he stands for one Carburettor with 30mm bore. In the course of the tests, we also tried a PHBH30 in a counter-test. We will present the result of this in the following part of this blog series.

On the topic crankshaft we trust king wave. Here we find exactly what we are looking for to build a high-torque, smooth-running and durable engine.

The choice falls on one king wave with 62mm stroke and 128mm connecting rod. Due to the 2mm longer connecting rod and increased stroke, we have the opportunity to work with the control angles by moving the cylinder using spacers on the cylinder head and the cylinder base in the stroke direction. The longer connecting rod in connection with the weighty crankshaft also brings a significant plus in smoothness.

The stroke of 62mm results Cubic capacity 252,4ccm - already very promising to build a torque-oriented engine.

The ignition should keep our tourer running smoothly, so we chose the one here bgm ignition with the PX pole wheel with a mass of 2300g.

The performance of the 252ccm unit is controlled by a bgm superstrong Clutch, the bgm primary 25-62 and one bgm Transmission with the graduation 12-13-17-20 passed on to the rear wheel. The short, fourth gear on the auxiliary shaft keeps the most frequently used gear more stable. With one tooth less in fourth gear, the teeth become significantly wider in the tooth base and thus offer a significantly higher load capacity than the variant with a gear wheel with one more tooth.

Concept and test plan

The requirement for the test setup is that we work from a rather good-natured touring design to a sporty design. Just to be able to depict a section through the possible variants. As a starting point for the test series, we set a basis with small control angles in order to be able to test as many sensible variants as possible later

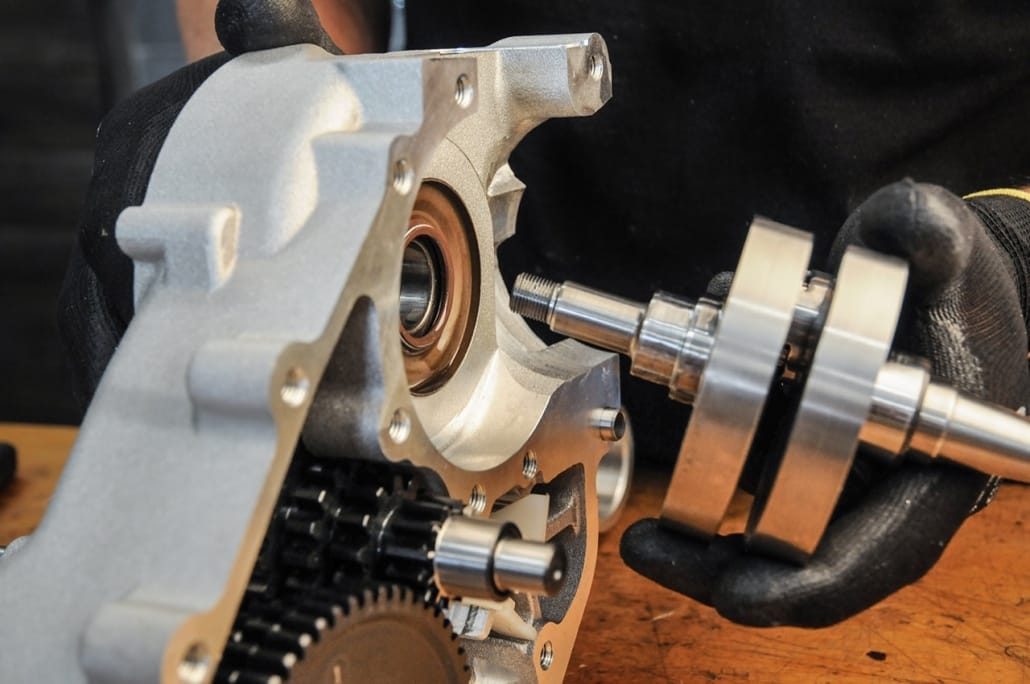

To determine a starting point, the crankshaft is mounted with bearing dummies and the cylinder is attached to determine the control angle.

Based on this initial data, we can consider to what extent we can sensibly set up the cylinder with spacers and work on the outlet in later stages of expansion.

After measuring back and forth a bit, we decide to start from the middle position of the control angle with one Transfer angle of 124 ° and a Outlet angle of 177 °.

Assembling the engine

Dream team: Malossi | bgm PRO | Kingwelle | Quattrini

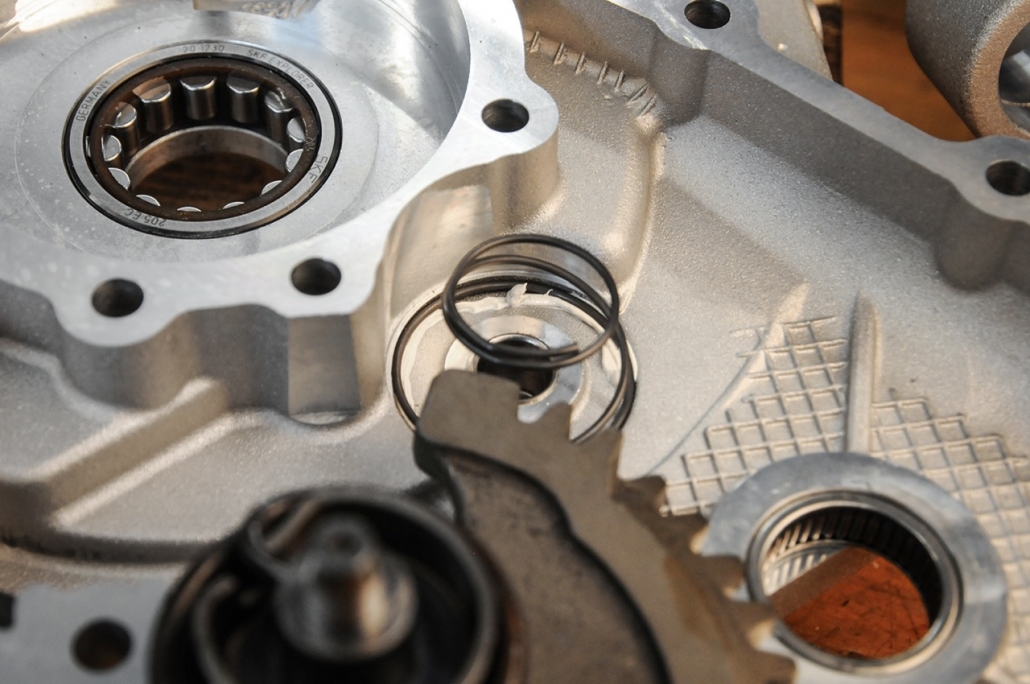

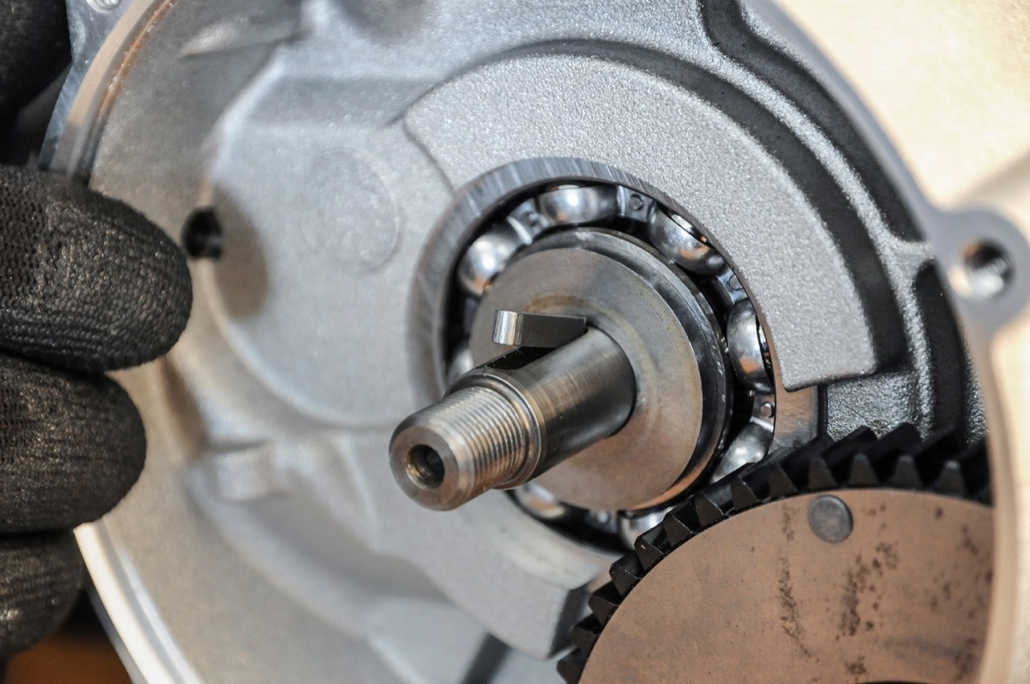

The factory new Malossi motor housing will be finished by king wave for the crankshaft with 62mm stroke and the enlarged diameter of the crank webs with 99,4mm. The bearing seat for the bearing on the alternator side is also checked and reworked in individual cases, as the bearing seat is manufactured by Malossi with a very tight tolerance.

We also offer the completely machined housing with a high-quality crankshaft from Kingwelle as a set. We use the set for this engine KWM46228.

The one attached by Malossi Bearing Kingwelle does not recommend 6205 for the alternator side. We follow Kingwelle's recommendation and use a here NU205.

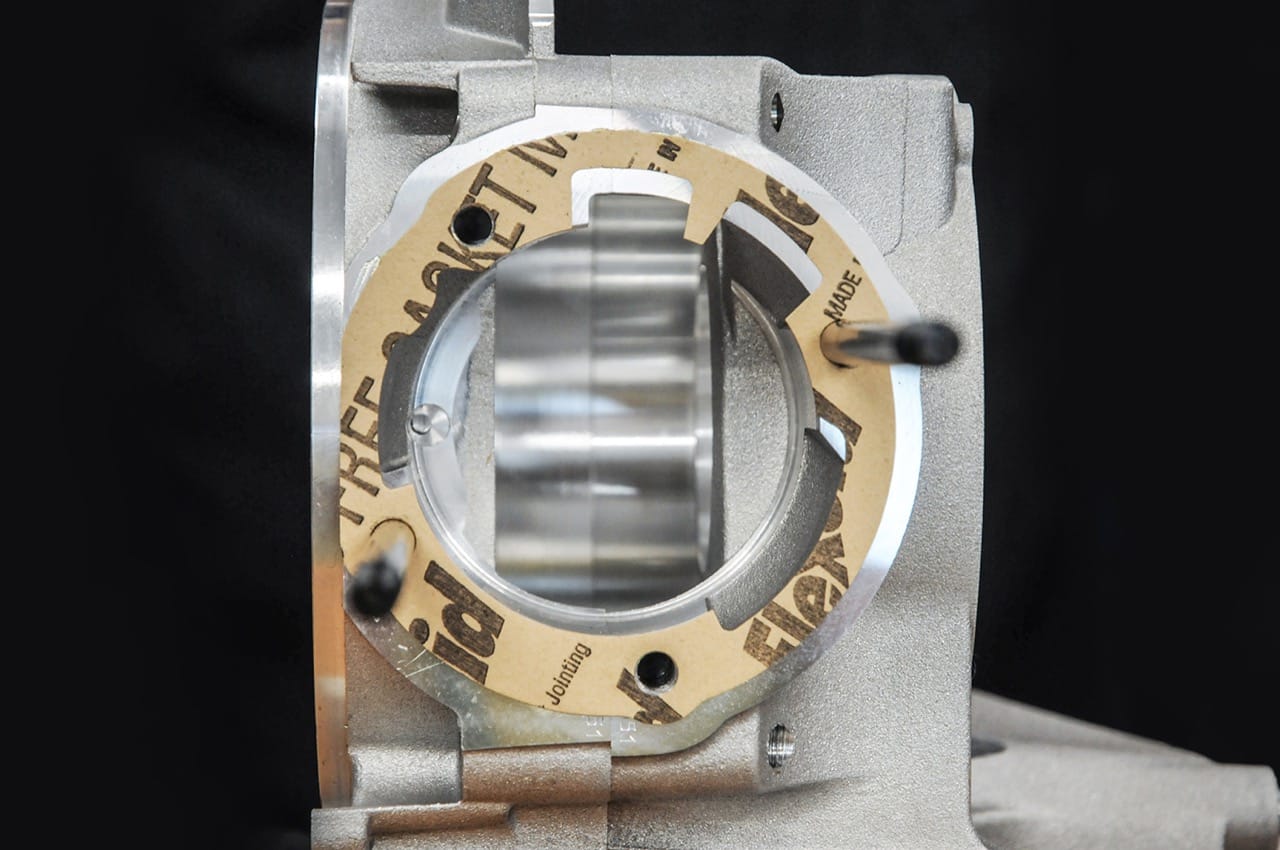

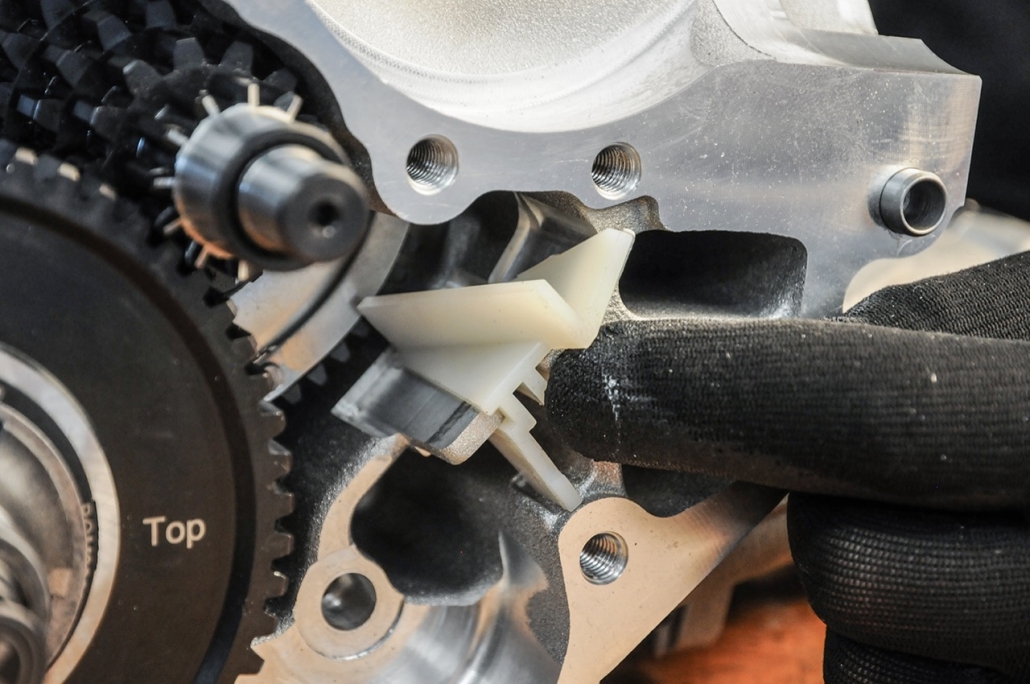

Before inserting the bearings, we process the motor housing and adapt the cylinder and the overcurrent ducts to each other. On a Piaggio engine case, this tends to degenerate into an evening event. The Malossi housing is already designed for the channels of the Malossi Sport and MHR cylinders and requires little rework for the Quattrini M244. Most of the work goes into removing the sealing surface on the cylinder base, which allows the M244 to be used on Piaggio engine housings.

Adjusting the transfer channels to the motor housing is done quite easily. The cylinder base seal shows how little needs to be adjusted here.

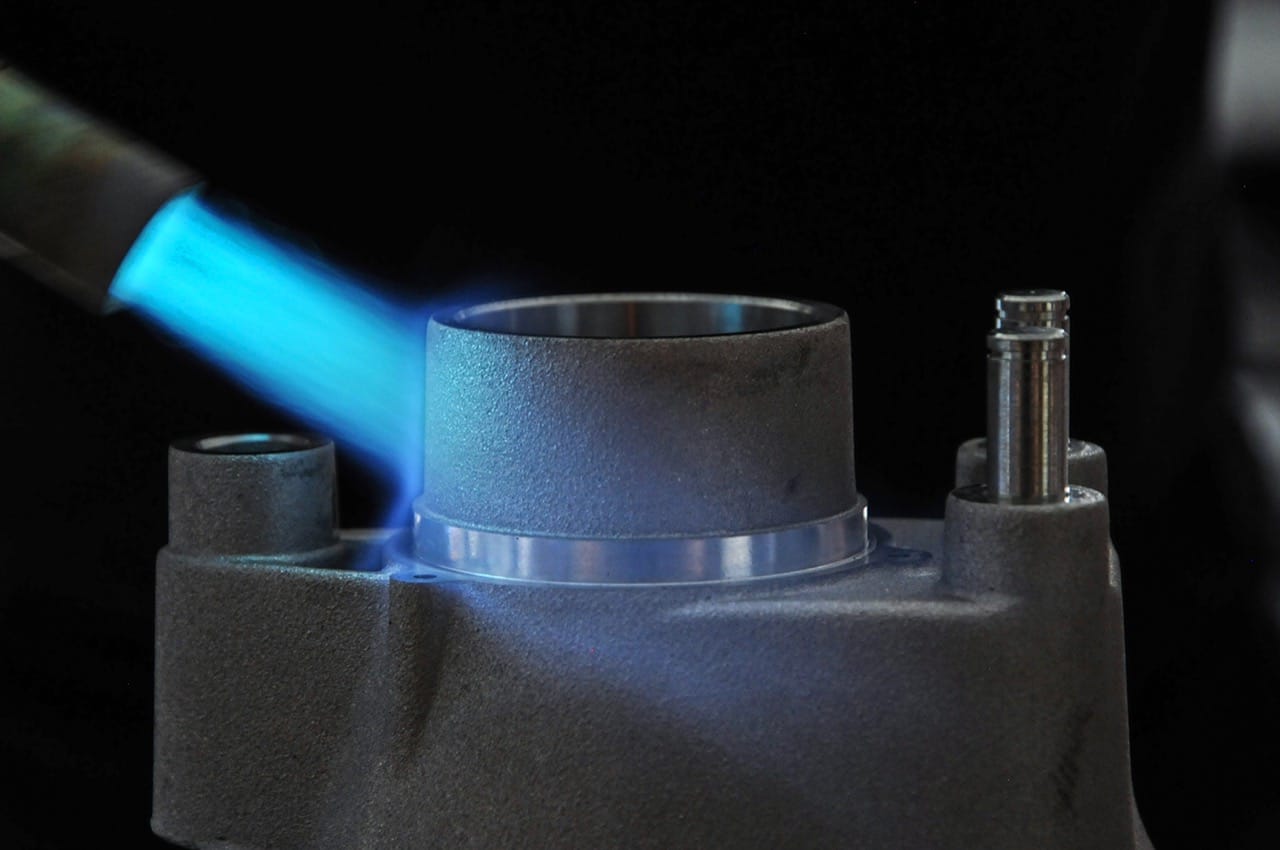

All bearings are traditionally used by shrinking in order to avoid damage to the bearing seats by simply pulling in the bearings. The shrinking or cold / warm process offers the advantage that no mechanical stress acts on the surface of the bearing seats and the seat is not widened as a result.

Wandering Malossi engine cases

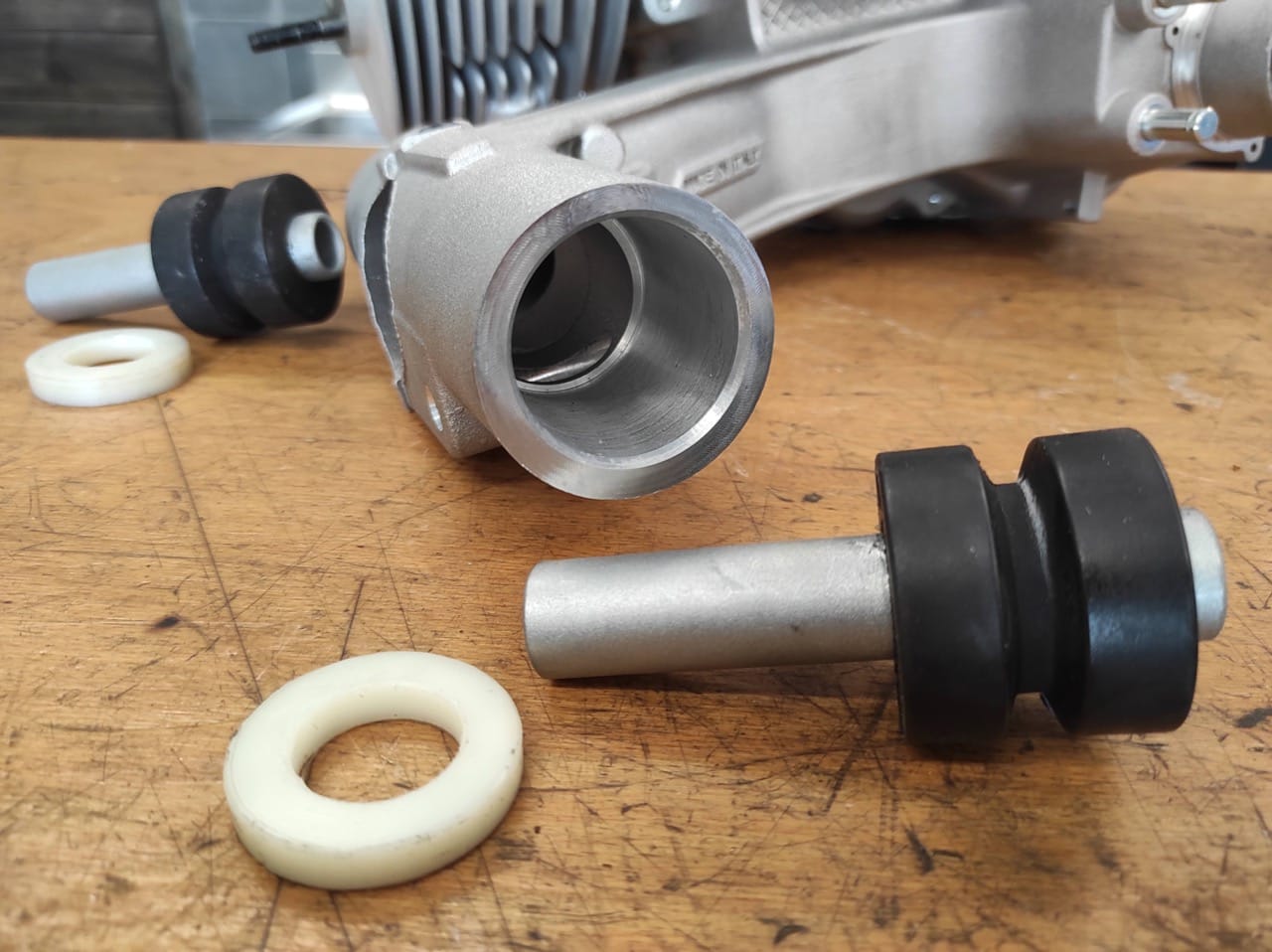

Another peculiarity of the Malossi motor housing is that the supplied original silent rubbers are too narrow for the motor housing. Or rather, here Malossi has simply oriented the seats for the silent rubbers deeper in the housing than was originally the case. This allows the motor housing to move over the silent rubbers in the direction of the frame.

We have been here with one quite a while ago Spacer set BGM7952SP A remedy was created for the silent rubbers and thus ensured a secure fit of the silent rubbers in the correct position.

The gear

The M244 with a 62mm stroke of the king shaft brought to 252ccm, will transfer a lot of torque to the rear wheel. A guarantee to achieve a high cruising speed at a reduced speed. That enables the primary. Starting from a massive and early onset of torque mountain, the primary can be selected to be long or even very long. With 25 to 62 teeth, we use the longest primary offered by bgm. The reinforced primary repair kit from bgm creates a durable primary drive.

Shift pins and crossbar are included threadlocking assembled.

The bgm secondary gear is set with the smallest possible clearance with the bgm shoulder rings.

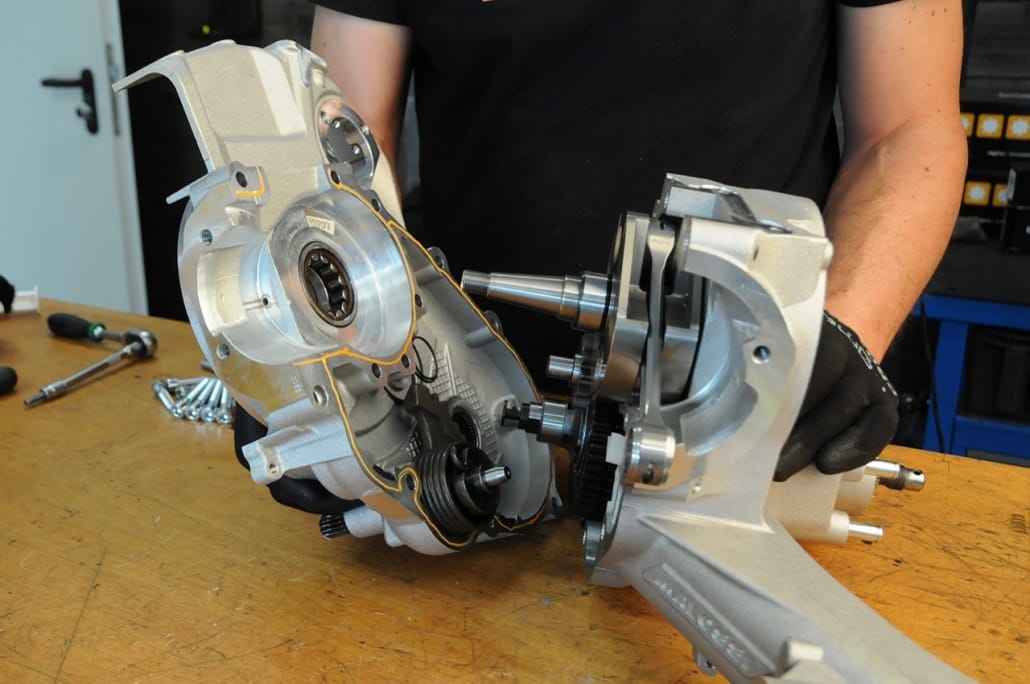

Assemble the Malossi motor housing

Further adjustments to the motor housing are no longer necessary and all other innards find their way into their place.

To assemble the crankshaft, the shaft sealing ring is moistened with a little oil so that the sealing lips slide cleanly onto the crankshaft and are not damaged.

The Malossi engine case, contrary to the Piaggio engine case, is without a solid seal composed. Instead of the paper seal, as in a modern engine concept, the housing is Surface seal sealed.

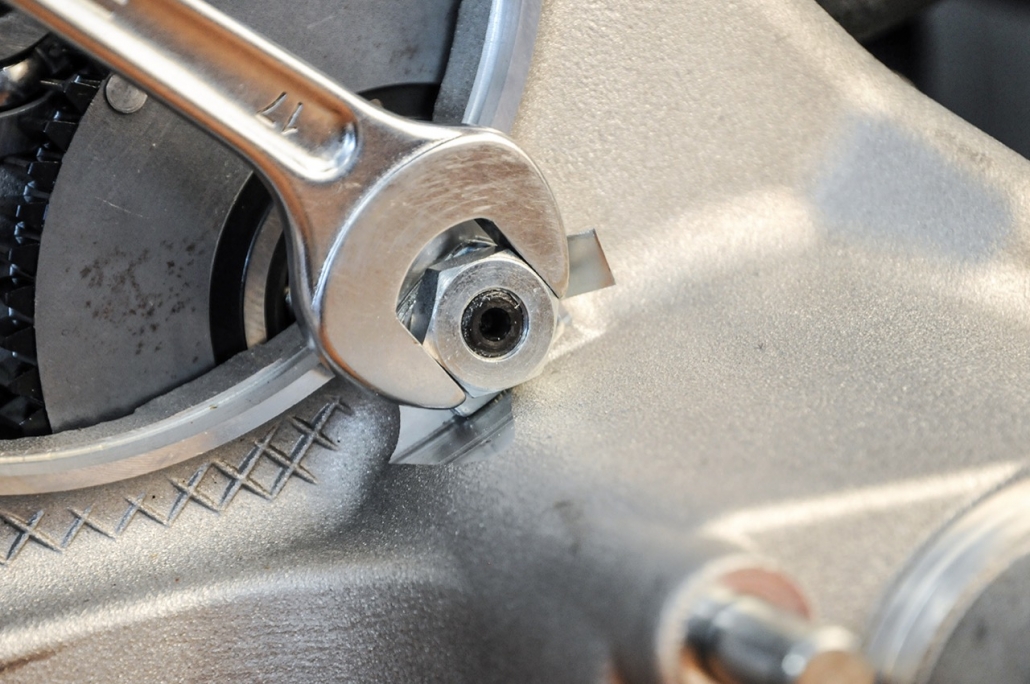

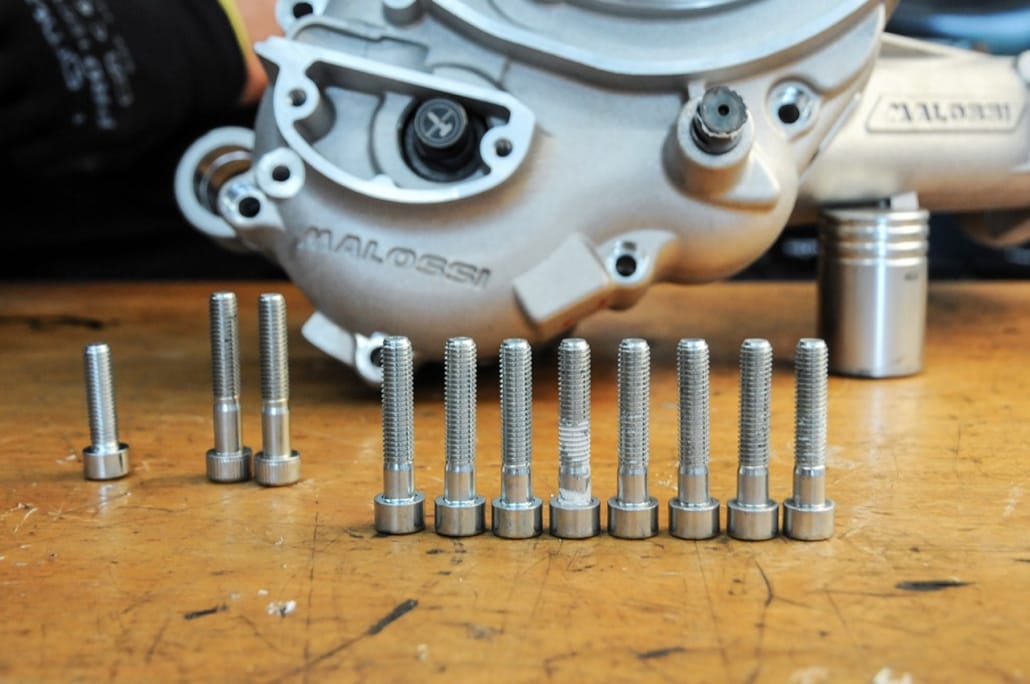

To connect the housing halves, Malossi uses M8 hexagon socket screws. Due to the different lengths of the screws used, a look at the Application listto find the correct attachment point.

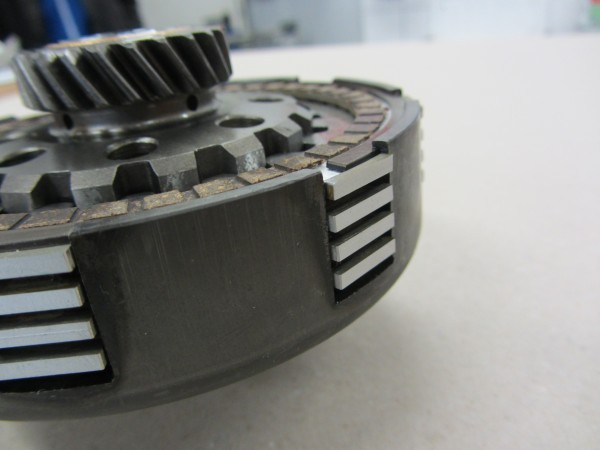

bgm PRO Superstrong clutch & King shaft

The King Shaft is supplied with its own thrust washer and special key. The thrust washer has a clear radius that fits exactly to the radius of the crankshaft. A breaking thrust washer is almost impossible.

The Kingwelle has a special feather key on the drive side, which is specially manufactured for Kingwelle and fits exactly into the groove of the coupling hub.

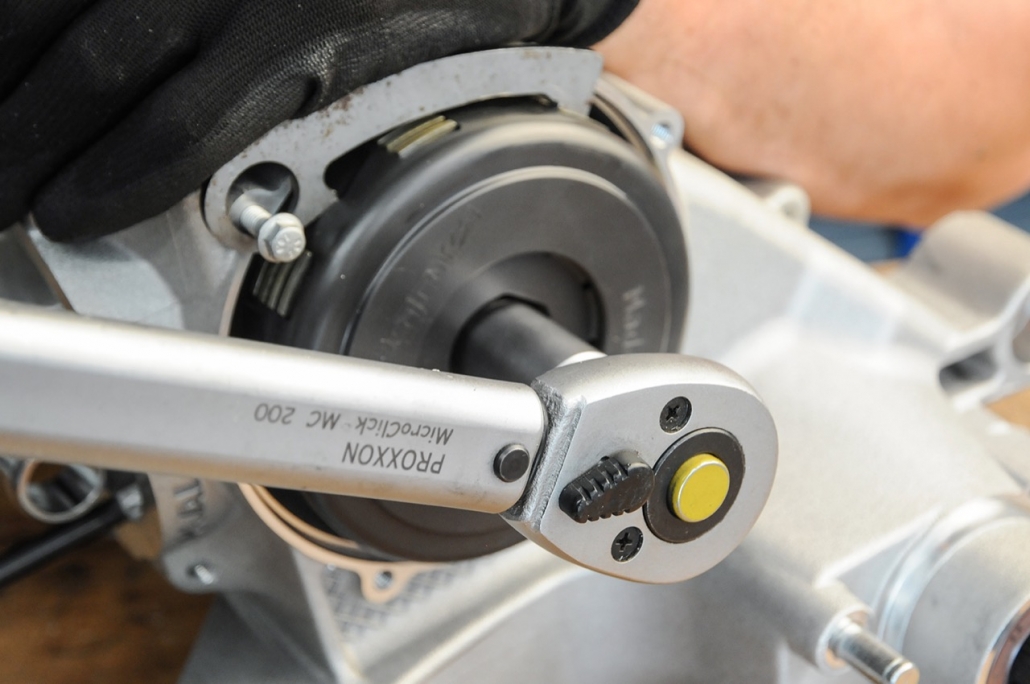

We use one as a coupling bgm Superstrong CR a. With the standard equipment, 10 bgm springs XL, the CR clutch manages a reliable transmission of power up to 40hp. The king shaft coupling nut has a fine thread of the dimension M12x1. The nut comes with screw lock and a Tightening torque of 70Nm attached.

Assembly of further components

The engine is then completed with the rest of the components.

Intake manifold with the Malossi 2-valve membrane. Clutch cover, switch latch, cover for the starter motor and the bgm ignition system with static ignition timing.

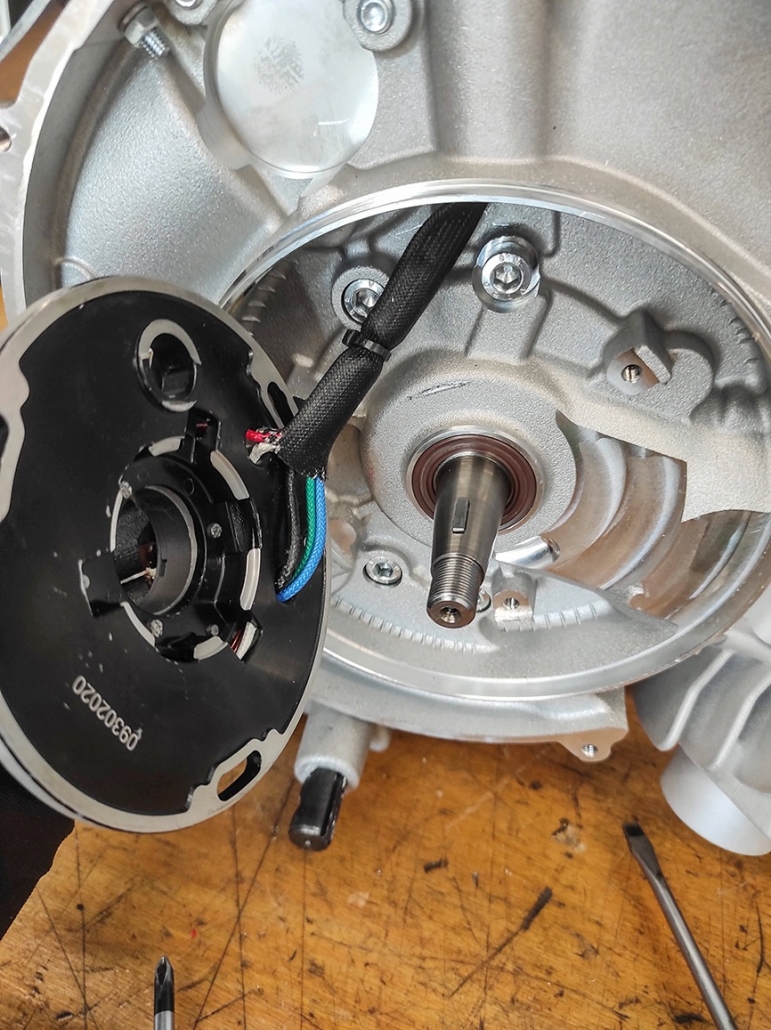

Stress-free assembly of the ignition base plate on Malossi engine housings

The Malossi motor housing is reinforced in many places. This can lead to contact between the base plate and the bearing seat when the ignition is installed. The base plate of the ignition must sit tension-free in the centering, so in individual cases the base plate and / or the motor housing must be slightly reworked to ensure a tension-free fit of the base plate.

Check crush dimension

Before the final assembly of the cylinder, we check the pinch size using solder.

Due to the increased stroke, we aim for the squeeze dimension in the range from 1.3mm to 1.4mm and set this using the enclosed cylinder base seals.

By compensating for the larger stroke, there is no need for centering on the cylinder head. For this reason, holes for fitting sleeves are made in the cylinder head and cylinder. The adapter sleeves prevent the spacers used for the cylinder head in the course of the test from protruding into the combustion chamber and causing unwanted damage there.

The new Quattrini engine on the test bench

For the test runs, we set the ignition to 19 ° BTDC.

The runs of the first expansion stage We will introduce M244_1 to you in the next blog post before…

Just a quick note - none of the runs were below the 30PS Mark on the unprocessed M244

bgm SUPERSTRONG Vespa Wideframe GS

The proven bgm SUPERSTRONG clutch is now also available for the Vespa GS150 / GS160 and SS180 models.

Ready-to-install coupling for your Wideframe Vespa

The bgm PRO coupling is delivered ready for installation. The scope of delivery includes

- the assembled coupling,

- a new lock washer,

- Clutch cover gasket and

- Crescent wedge

We also recommend the same Pressure plate and the separating mushroom to replace, available here in a practical set!

The Superstrong GS coupling replaces the serial coupling of the GS / SS models 1: 1 and can usually * be used without further modifications. The clutch is available with 22 teeth (like original) or with 23 teeth (longer stocky). Helical teeth for use with the standard 67-tooth primary gear.

The bgm SUPERSTRONG 2.0 Ultralube coupling combines:

- extreme durability,

- absolute reliability and

- easy operation

It is the foundation of any solid Vespa engine tuning. The CNC-manufactured clutch basket has excellent concentricity and extremely high torsional rigidity. The Vespa clutch thus offers perfect coupling behavior with a clearly defined grinding point and clean separation of the clutch linings.

It is suitable for that Touring riderwho values high quality, as well as ambitious ones Racer, the one extremely resilient and stable coupling .

ULTRALUBE

The latest generation of Superstrong clutches now has an innovative new technology: Ultralube.

Ultralube pumps (through precisely defined bores and centrifugal force) transmission oil both into the highly stressed hub profile (between clutch basket and clutch hub) and onto the clutch linings themselves.

This in the Vespa area unique technology makes the legendary Superstrong 2.0 clutch even more stable than it already is. A clutch designed to last.

PERFORMANCE

The ready-to-install clutch is designed for a power range up to approx. 20PS / 22Nm by means of the mounted clutch springs. Reinforced springs (sold separately, bgm PRO XXL Reinforced clutch spring) expand the performance range of the clutch to over 40 hp. It is still easy to operate.

DELIVERY

The scope of delivery includes the complete ready-to-install clutch with bgm PRO Cosa clutch facings and ten BGM PRO XL springs. A new O-ring for the clutch cover and a new crescent wedge are also included.

RECOMMENDATION

We also recommend a low-alloy gear oil of classes API GL3 / GL4 for high-performance engines in order to prevent the clutch from slipping even under extreme loads. This also applies to our bgm Superstrong couplings. The old engine oil specification SAE30 corresponds to today's transmission oil specification SAE 85W / 90. We recommend this as a lubricant bgm PRO Street gear oil (BGM2025, corresponds to specification API GL-3).

* In some cases it may be necessary to rework the clutch cover and arm, see Instructions & Video:

Instructions for installation and adaptation

You can also find the installation instructions here: Instructions

Tool list:

TIPP: Toptul tool

- Ratchet; SW10

- Slotted screwdriver sizes 5 to 6

- Ratchet; SW14

- Open-end wrench SW19

- Torque wrench up to 100Nm

- Clutch holding tool

- Clutch puller

Item list, alternatives and accessories

- Complete clutch, 22 teeth (Reduction as original)

- Coupling complete 23 teeth (Reduction 5% longer)

- Clutch basket and hub, loose

- Lock nut clutch hub (ET to the coupling)

- Clutch spring XL (ET to the coupling)

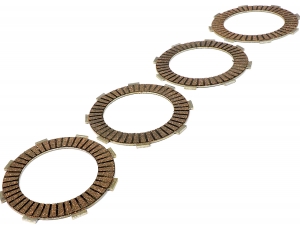

- Clutch linings BGM type Cosa (ET to the coupling)

- Clutch linings BGM Touring, Type CR (alternative)

- Clutch pressure plate PX200, (Accesories)

- O-ring coupling arm (Accesories)

- Coupling nut (Accesories)

- Spring washer M10 (ET to the coupling)

- Puller clutch

- Vespa clutch holder

Vespa Cosa clutch plates bgm PRO Touring Alu

bgm PRO Touring Alu - our new clutch linings from bgm PRO - now retrofit a Vespa Cosa clutch with the properties of the Honda CR80 clutch linings

The bgm PRO Touring Aluminum facings are greatly improved clutch discs for all Cosa clutches. Revolutionary clutch linings in the Honda CR80 style with significantly more surface, but that Plug & Play fit into the normal Cosa couplings!

Clutch linings BGM PRO TOURING Alu type COSA2

- Perfect symbiosis of racing technology and reliability for touring riders

- Suitable for all conventional Cosa2 clutch baskets (strap width as original, 14mm)

- Aluminum carrier material with reinforced contact surface on the tabs

- Sinter pad material such as Honda CR80 in a wide design

The bgm PRO Touring aluminum pads combine the advantages of the popular CR80 racing pads with the high demands of touring riders.

Buy clutch linings hereVespa Cosa clutch upgrade

SOLID BASE BRACKET

The linings use an aluminum carrier, the lugs of which have a large contact surface for the clutch basket. This makes the coverings very stable over the long term. The slow shearing of the tabs, which often occurs with conventional decks with steel girders, is completely eliminated due to the large contact surface. The aluminum also makes the coupling more thermally resilient. This is a great advantage in extreme situations (e.g. starting with a heavy load on a steep mountain pass), but also offers a reassuring reserve in everyday life. The width of the flaps is made to fit precisely, so that the pads are almost free of play in the basket.

DURABLE AND GRIPPLE MATERIAL

The lining material for the clutch discs is the same for the bgm PRO TOURING aluminum linings high quality sintered material as used for the CR80 racing pads. Due to the larger contact surface in the TOURING variant, the coupling is softer and not aggressive. The large support surface also improves durability.

FULLY COMPATIBLE

The bgm PRO TOURING aluminum clutch linings are available as 1: 1 replacement for conventional Cosa2 clutch facings designed. They harmonize perfectly with the standard steel discs.

The thickness of the pad package corresponds to that of the original, which means that no shims or spacers have to be used. The pads fit into all serial clutches of the Vespa Cosa2 models, into the PX125-200 models from year of construction 1998 as well as into all vehicles that have been retrofitted with a Cosa2 clutch. The linings are also compatible with clutches / clutch baskets based on the Cosa2 technology, e.g. clutch –SC-, MMW, Scooter & Service or Ultrastrong. (Strap width as original = 14mm)

NOT SUITABLE

The pads are not suitable for clutches / baskets that have been specially manufactured to hold the CR80 clutch pads, e.g. BGM PRO Superstrong 2.0 CR80, ONKEL MIKE 'DDOG' CNC or similar (strap width CR80 = 16mm)

DELIVERY

The set includes:

- 1x clutch cover plate (one-sided covering)

- 3x clutch friction disks (facing on both sides)

Sufficient for a Cosa2 coupling.

CONCLUSION: The BGM PRO TOURING aluminum clutch linings are an ideal upgrade for your Vespa Cosa2 clutch.

Buy clutch linings hereHemos mejorado aún more nuestro embrague more popular para the Vespa

La última version de nuestro Embrague for the Vespa called Superstrong 2.0 Ultralube ©. Está diseñado realmente para todos los motors, desde los motors originales de la Vespa PX125 hasta los potenciados con 40cv.

Hemos sacado provecho a las amplias experiencias obtenidas a lo largo del tiempo para desarrollar el embrague Superstrong 2.0 Ultralube.

Lubrificación patentada del embrague

Gracias al nuevo diseño de la carcasa de embrague, with the motor encendido el lubricante de engranaje resbala por el embrague para lubrificar la arandela de embrague y the polígono responsable de la transmission de potencia.

The technology establecida con los discos de embrague CR permits una manipulation al 100% controlada and un cambio de marchas absolutamente preciso, independent of the torque o la potencia transmitida a la rueda trasera.

Esta nueva tecnología Ultralube lleva la Superstrong 2.0 as siguiente nivel y Guarantee a placer de conducción único y permanente.

Lubrificación única - desgaste reducido

Este nuevo embrague es el único de tipo Cosa que cuenta con la lubrificación de las partes que se encargan de la transmission de potencia para así Disminuir significativamente el desgaste del cubo de embrague.

Actualmente, la version CR del embrague BGM Superstrong 2.0 Ultralube está available con los siguientes desarrollos:

Compatible with the piñones elásticos de 67 and 68 served

- ref. BGM8420; Embrague -BGM PRO Superstrong 2.0 CNC Ultralube, type Cosa2 / FL (CR80) - para piñón elástico de 67/68 served - 20 served

- ref. BGM8421; Embrague -BGM PRO Superstrong 2.0 CNC Ultralube, type Cosa2 / FL (CR80) - para piñón elástico de 67/68 served - 21 served

- ref. BGM8422; Embrague -BGM PRO Superstrong 2.0 CNC Ultralube, type Cosa2 / FL (CR80) - para piñón elástico de 67/68 served - 22 served

- ref. BGM8423; Embrague -BGM PRO Superstrong 2.0 CNC Ultralube, type Cosa2 / FL (CR80) - para piñón elástico de 67/68 served - 23 served

Compatible with the piñones elásticos de 64 and 65 served

- ref. BGM8322; Embrague -BGM PRO Superstrong 2.0 CNC Ultralube, type Cosa2 / FL (CR80) - para piñón elástico de 64/65 served - 22 served

- ref. BGM8323; Embrague -BGM PRO Superstrong 2.0 CNC Ultralube, type Cosa2 / FL (CR80) - para piñón elástico de 64/65 served - 23 served

- ref. BGM8324; Embrague -BGM PRO Superstrong 2.0 CNC Ultralube, type Cosa2 / FL (CR80) - para piñón elástico de 64/65 served - 24 served

Compatible with the piñónes elásticos de 62 y 63 served

También os ofrecemos el embrague con serves rectos para motores que tiran mucho y motores con otro eje piñón múltiple, puesto que es extremadamente sólido y funciona sin problemas:

- ref. BGM8623; Embrague -BGM PRO Superstrong 2.0 CNC Ultralube, type Cosa2 / FL (CR80) - para piñón elástico de BGM de 62/63 served (rectos) - 23 served

- ref. BGM8624; Embrague -BGM PRO Superstrong 2.0 CNC Ultralube, type Cosa2 / FL (CR80) - para piñón elástico de BGM de 62/63 served (rectos) - 24 served

- ref. BGM8625; Embrague -BGM PRO Superstrong 2.0 CNC Ultralube, type Cosa2 / FL (CR80) - para piñón elástico de BGM de 62/63 served (rectos) - 25 served

¡The design and technology of the embrague Ultralube © son protections por modelo de utilidad!

De nouveau en stock: pieces de tuning de BGM pour Lambretta

Les cylindres Racetour d'une cylindrée de 195cc et 225cc et l'embrayage Superstrong de 46 dents, qui s'adapte parfaitement aux cylindres RT, sont de nouveau available!

Cylinder BGM Racetour 225cc for Lambretta

Tuning cylinder -BGM PRO MRB-Racetour 225cc- Lambretta TV 200, SX 200, DL 200, GP 200.

Lors du développement du cylindre Racetour, Mark Broadhurst a utilisé sa longue expérience en matière de tuning des Lambrettas (avec plus de 1.700 cylindres trafiqués). The cylinder is available with a cylinder of 195cc (size Ø = 65mm) for carters moteur petits de 125 à 175cc et de 225cc (alésage Ø = 70mm) pour les carters moteur de 200cc.

Achetez cylinder for LambrettaEmbrayage BGM Superstrong de 46 dents for Lambretta

Embrayage de tuning -BGM PRO Superstrong 6 disques d'embrayage garnis, 10 departments- Lambretta LI, LIS, SX, TV (série 2, série 3), DL / GP -

BGM PRO Superstrong - l'original

Embrayage extrèmement résistant et facile à utiliser - Made in Germany

L'embrayage Superstrong allie of the attribute tels que résistance, fiabilité et une utilization facile.

This is the base de n'importe quel moteur trafiqué.

La cloche d'embrayage massive usinée en CNC assure une concentricité parfaite et offre une haute rigidité de torsion, tout en garantissant un bon enclenchement et accouplement avec un point de patinage bien défini et le tout avec une souplesse sans égal. Cet embrayage est ideal tant pour les Lambrettistes randonneurs qui accordent une grande importance à la qualité que pour les Lambrettistes de compétition qui sont à la recherche d'un embrayage resistant et durable.

bgm tuning Lambretta highlights back in stock

Besides ours bgm catalog 2018 we have another piece of news for you. Our two bgm tuning parts for Lambretta are now available again: 225cc RT cylinder and the Lambretta Superstrong clutch.

bgm Racetour 225 Lambretta cylinder

bgm tuning Lambretta cylinder -BGM PRO MRB-Racetour 225cc- Lambretta TV 200, SX 200, DL 200, GP 200.

In the development of the RaceTour cylinders Mark Broadhurst incorporated his decades of experience in the tuning of Lambretta scooters and over 1,700 tuned up 2-stroke cylinders. The bgm tuning cylinder for Lambretta are available with 195cc (Ø=65mm) for the small casings (125 – 175cc) as well as with 225cc (Ø=70mm) for the 200cc casings.

Buy here Lambretta cylinderbgm Superstrong clutch Lambretta 46 teeth

bgm Tuning Lambretta clutch -BGM PRO Superstrong 6 discs, 10 springs- Lambretta LI, LI S, SX. TV (series 2-3), DL / GP -

BGM PRO Superstrong - the original

Extremely durable clutch, easy to use - Made in Germany

The Superstrong clutch is extremely durable, absolutely reliable and easy to use. Perfect for efficient tuning.

The massive CNC-machined clutch spider features an excellent concentricity and is highly durable. Therefore it offers a perfect clutch engagement and a clear disengagement. This clutch is ideal for tour riders who place value on high quality as well as for racers who look for extremely durable and stable clutch.

Buy here Lambretta clutch

Nuovamente disponibili gruppo termico e frizione bgm tuning by Lambretta

In addition to the new catalog bgm 2018 abbiamo per te un'altra buona notizia: tornano ad essere disponibili due pregiati articoli bgm for the tuning of your Lambretta: the group termico Racetour 225cc and the friction Superstrong a 46 denti, perfect for the group termico Racetour:

Gruppo termico bgm Racetour 225 with Lambretta

Gruppo termico bgm Tuning Lambretta-BGM PRO MRB-Racetour 225 cc- Lambretta TV 200, SX 200, DL 200, GP 200.

Nella progettazione del gruppo termico RaceTour Mark Broadhurst has unito la sua esperienza pluridecennale nel tuning della Lambretta so come nell'elaborazione di oltre 1700 cilindri a 2 tempi. Ci sono cilindri bgm tuning da 195cc (alesaggio 65mm) per carter piccoli da 125-175cc e cilindri bgm tuning da 225cc (alesaggio 70mm) per carter motore da 200cc.

Acquista qui il groupo termico per LambrettaFrizione bgm Superstrong 46 denti per Lambretta

Frizione bgm Tuning Lambretta-BGM PRO Superstrong 6 dischi, 10 molle- Lambretta LI, LI S, SX. TV (series 2-3), DL / GP -

BGM PRO Superstrong - l'originale

La frizione Superstrong unisce ottima resistenza, assoluta affidabilità e facile utilizzo - Made in Germany.

The basis for an ottimo tuning of the engine.

Il cestello della frizione, massiccio e realizzato con lavorazione CNC presenta un'eccellente rotondità so come un'elevata rigidità. Tutto questo consente di ottenere innesto e stacco della frizione perfetti. Ideal per chi percorre lunghi tragitti e desidera componenti di ottima qualità, so come per gli amanti delle competizioni alla ricerca di una frizione resistant e stable.

Piezas tuning de BGM for Lambretta innovations available

Tanto el cilindro RT de 195cc como el de 225cc vuelven a estar available! Además acabamos de recibir otra vez el embrague Superstrong con 46 served que se adapta perfectamente a dichos cilindros.

Cilindro 225cc bgm Racetour para Lambretta

Cilindro tuning -BGM PRO MRB-Racetour 225cc- Lambretta TV 200, SX 200, DL 200, GP 200.

A la hora de desarrollar el cilindro RaceTour, Mark Broadhurst hizo uso de su amplia experiencia en el ámbito del tuning de Lambretta - con más de 1.700 cilindros preparados. Dicho cilindro is available with a cilindrada de 195cc (orificio Ø = 65mm) for the carcasas de motor de 125-175cc y con 225cc (orificio Ø = 70mm) for the carcasas de 200cc.

Comprar cilindro race tourEmbrague Superstrong con 46 served the BGM for Lambretta

Embrague tuning -BGM PRO Superstrong 6 discos de embrague, 10 muelles- Lambretta LI, LIS, SX, TV (series 2, series 3), DL / GP -

BGM PRO Superstrong - the original

Embrague extremadamente resistant, fácil de manipular - Made in Germany

Este embrague Superstrong aúna una resistencia y fiabilidad maximas y un manejo sencillo.

Constituye la base de cualquier preparation de motor fiable.

La carcasa de embrague mecanizada en CNC destaca por su rotación precisa resultando en un acomplamiento ideal y una separación de embrague con suavidad. Se presta perfectamente tanto para el conductor de scooter quien viaja a menudo y prefiere comprar productos de alta calidad, como para el motociclista de carreras quien necesita un embrague extremadamente resistant y durable.

bgm Tuning Lambretta Highlights available again

Suitable for the new one bgm catalog 2018, are now two bgm Tuning Lambretta Essentials back in stock. Our 225cc RT cylinder and the Lambretta Superstrong clutch with 46 teeth, which harmonizes very well with the cylinder, are now available again:

bgm Racetour 225 Lambretta cylinder

bgm Tuning Lambretta cylinder -BGM PRO MRB-Racetour 225 cc- Lambretta TV 200, SX 200, DL 200, GP 200.

Mark Broadhurst has incorporated his experience from several decades of Lambretta tuning and over 1.700 tuned two-stroke cylinders into the development of the RaceTour cylinders. The bgm Tuning Lambretta cylinders are available with 195ccm (65mm bore) for the small engine cases with 125-175 ccm and with 225ccm (70mm bore) for the 200ccm engine cases.

Buy Lambretta cylinders herebgm Superstrong clutch Lambretta 46 teeth

bgm Tuning Lambretta clutch -BGM PRO Superstrong 6 discs, 10 springs- Lambretta LI, LI S, SX. TV (series 2-3), DL / GP -

BGM PRO Superstrong - the original

Extremely resilient coupling, very easy to use - Made in Germany

The Superstrong coupling combines extreme durability, absolute reliability and easy operation.

It is the basis of any solid engine tuning.

The massive, CNC-manufactured clutch basket has excellent concentricity and extremely high torsional rigidity. It thus offers perfect coupling behavior with a clearly defined grinding point and clean cutting. It can be used by touring riders who value high quality, as well as ambitious racers who are looking for an extremely resilient and stable clutch.

Assembly aid for Lambretta Superstrong clutch

For our BGM Superstrong Lambretta clutch, we can now also offer the right centering aid for inserting the springs.

With the centering aid BGM8011TL2 it is very easy to position all springs in their place of use during assembly.

The clutch with built-in clutch compressor system

The BGM Superstrong for Lambretta already has a "built-in" clutch compressor system.

The coupling comes with two screws and long nuts for this purpose.

On the face of the coupling spider, two of the legs are marked with a point, at the bottom of which is the threaded hole for the screw.

Fully practical - and very easy to use:

The screws for pre-tensioning the base plate are threaded in here.

The cut-out in the centering aid exposes areas for the tall nuts, which are used to preload the coupling for assembly.

Very simple: as soon as the coupling is pre-tensioned, the centering aid can simply be pulled out.

Superstrong - the bgm PRO clutches for Vespa and Lambretta

Bgm - this is the brand of Scooter Centers, the word has got around so far and is no secret - on the contrary. In 2017 we are celebrating 25 years Scooter Center and all of our experience and know-how flows into our bgm products. We are proud of bgm and ours Superstrong clutches.

The highlights in product development were certainly the

- Superstrong clutches for Vespa and Lambretta

- Shock absorber for Vespa with TÜV

- BigBox exhaust systems for Vespa and Lambretta

- RT cylinder kit for Lambreta and Vespa

Superstrong - the label keeps what it promises

The bgm PRO coupling is THE plug & play solution - Made in Germany.

The superstrong Clutch united

- extreme durability,

- absolute reliability and

- easy operation.

The massive, CNC manufactured clutch basket offers excellent concentricity and superb torsional rigidity. It thus offers perfect coupling behavior with a clearly defined grinding point and clean cutting. It can be used by touring riders who value high quality, as well as ambitious racers who are looking for an extremely resilient and stable clutch.

bgm PRO SUPERSTRONG couplings are back in stock

Here you come directly to the Superstrong couplings in the Scooter Center Shop

Our best Vespa clutch is back in stock

In time for the summer season is ours bgm Superstrong clutch for the Vespa Largeframe Models available again. The robust and reliable coupling is so popular that we were unfortunately sold out at times.

New generation of friction disks for the Vespa clutch

From now on we deliver the bgm superstrong and the Superstrong CR with a new generation of steel discs. Did you know that the steel discs should be installed in a certain order?

Vepsa Superstrong clutch for Vespa Largeframe P1390241

The new clutch is each disc is clearly markedso that it is always clear in which position it should find its place.

bgm Superstrong - new friction discs for the Vespa clutch

All lenses have been redesigned and the fit has been optimized.

The disc at position two was given a defined curvature in a specially designed radius so that a clean separation behavior is achieved under every load condition when the clutch is operated.

The steel disks are subject to series testing, during which we always keep an eye on the concentricity and the planar quality, as well as the material quality and hardness. All steel disks are here in the 10hrc range.

Except for the optimization of the steel discs, nothing changes in the proven and stable concept of the Superstrong clutch for Vespa PX, T5, Sprint, Rally etc.

NEW: clutch bgm PRO Superstrong “CR” for Vespa

Our 1000 times proven bgm PRO Superstrong clutch for the Vespa Largeframe-Engines received an update.

In the version "Superstrong CR”The CR clutch facings can be assembled without machining.

Pre-assembled coupling available

Only the upper surface is specially processed and offers space for the reinforcement of the cover plate.

Nothing changes in the mere assembly of the coupling itself.

Easy construction

As a rule, as with the Cosa version of the Superstrong, it is sufficient to machine the clutch cover.

The necessary Information about this you can find in Article download area in our shop.

The clutch basket of the CR version has not increased in outer diameter.

We only changed the contour so that the CR pads fit without machining.

All other components such as the hub, pinion and steel disks are identical to those the Superstrong Cosa version.

New Vespa clutches:

The Superstrong CR is available in the following versions:

Plug & Play

Vespa PX80/PX125/PX150/Cosa125/Cosa200 (the large primary gear has 67 or 68 teeth)

- BGM8296; Clutch -BGM Superstrong CR - 20 teeth

- BGM8297; Clutch -BGM Superstrong CR - 21 teeth

- BGM8298; Clutch -BGM Superstrong CR - 22 teeth

- BGM8295; Clutch -BGM Superstrong CR - 23 teeth

Vespa PX200 (the large primary gear has 65 teeth or the BGM primary gear has 64 teeth)

- BGM8299B; Clutch -BGM Superstrong CR - 22 teeth

- BGM8299; Clutch -BGM Superstrong CR - 23 teeth

- BGM8299D; Clutch -BGM Superstrong CR - 24 teeth

Kit

Alternatively, you can of course also put together your own CR coupling.

- BGM8290; Clutch basket -BGM Superstrong CR

- BGM8290SIUP; Cover plate -BGM PRO type CR- for BGM Superstrong CR coupling

- 7672101; Clutch lining -Newfren type CR- for BGM Superstrong CR

Recommendation for torque monsters

For high-torque motors, we recommend that you change the Primary gear to 64 teeth also a reinforced repair kit. The stronger springs offer better shock absorption and mechanically digest the higher torque of the Monster motors better than their series counterparts.

Advantages of the CR rubbers

We have the advantages of CR pads on powerful engines in Contribution of the covering sets already mentioned. Here is an excerpt from it again:

"Why can such a small, flat clutch lining work better than the larger cork lining?"

In addition to the lining material with a better coefficient of friction, the keywords here are “effective radius”.

The decisive factor is the outer diameter in connection with the height of the covering and the resulting radius.

This means that the lever arm facing the torque acting on the hub is longer with the same outer diameter because the center of the lining is further away from the pivot point of the shaft. In the end, the simple law of leverage. It is therefore “easier” for the clutch lining to cope with the torque introduced. So he literally sits on the longer lever.

On the one hand, it is the common, ubiquitous physics and, on the other hand, the type of lining material that enables a clutch with CR linings to transmit a higher torque with the same pressure of the springs.

A CR pad set enables a clean and freely separating clutch with very little lever travel. The lining material also enables very simple and safe switching operations at high speeds.

Gear oil for clutches with CR facings

We recommend an oil with the specifications Jaso MA / MA2 or API GL-4 as a lubricant for these clutch linings.

For example that Valvoline 10W40 MA2.

Upgrade for the Vespa Cosa2 clutch types!

More power, more torque, more everything ... This is what the new Malossi MHR221, Quattrini M232 & Co. motors offer.

The concentrated torque of these units has to reach the road somehow.

One of the most important interfaces between the steam hammer and the road is also the coupling.

She has one of the toughest jobs to do in the engine. On the one hand, every little bit of torque should be transmitted to the transmission with as little loss as possible and, on the other hand, reliability, durability and ease of use should be a matter of course.

Up until now, the rule that applied to Vespa clutches was that the more power you want to keep in check, the higher the spring strength you have to choose for the cork clutch linings.

Such an “improved” clutch, however, often requires almost Herculean effort to operate. The clutch lever is really just incredibly difficult to pull - so no real solution either ...

In order for the coupling to reliably provide propulsion over the long term, the spring force would have to be increased at engine outputs of over 35 HP and the resulting torque in such a way that the surface pressure of the cork coverings reaches its limits.

The natural material cork begins to behave like a sponge at high pressures and thereby influences the grinding point and the behavior of the clutch. The material is simply overwhelmed by the plastic deformation, the acting torque and the mechanical load during sliding friction. If the cork material has slipped under such a high load, i.e. the clutch has slipped, the surface of the covering burns and the material can no longer build up adhesion to the steel disc.

But how do you get a well-functioning clutch with low operating forces and a high level of transmissible torque?

The only remedy here is a different pad material with a better coefficient of friction and a trick from physics ...

Pad material from the motorcycle sector is considered to be very resilient. Unfortunately there are no pads here that would fit directly into a Vespa clutch.

That's why we have clutch linings machined to match, which are used, for example, in the VFR400 and the Honda CR.

Due to the processing, the clutch linings without further changes to the existing components in the well-known Cosa couplings.

The upper lining has to take on the task of the cover plate like a normal Cosa coupling.

This covering is also machined on the upper side so that there is space for the circlip.

The lining package itself and the necessary processing change the overall height of the lining package. The CR rubbers are a bit flatter in the package than the original Piaggo cork rubbers.

In order to compensate for this dimension and to give the upper surface more stability, a washer can be inserted as reinforcement at this point.

When retrofitting a Superstrong or a conventional Cosa coupling, it must be checked in each individual case whether this washer is absolutely necessary as a spacer.

The base of the CR coverings is made of a high-strength aluminum material and is much thicker than the steel base of a conventional cork surface.

This fact helps the noses to be more resistant to knocking out on the clutch basket. However, if the springs of the shock absorbers in the primary drive are broken or slack, even wide noses on the clutch linings will not help. The force peaks are passed on to the clutch unhindered. One remedy here reinforced shock absorber set.

The stronger noses of the CR clutch linings also lie on a larger area in the clutch basket of the “Cosa variant” of the Superstrong.

In comparison here with a Piaggio Cosa surface. On the left the adapted CR clutch lining - on the right Piaggio Cosa.

When looking at the CR pads, however, one clearly asks: "Why can such a small, flat clutch pad work better than the larger cork pad?"

In addition to the lining material with a better coefficient of friction, the keywords here are “effective radius”.

The decisive factor is the outer diameter in connection with the height of the covering and the resulting radius.

This means that the lever arm facing the torque acting on the hub is longer with the same outer diameter because the center of the lining is further away from the pivot point of the shaft. In the end, the simple law of leverage. It is therefore “easier” for the clutch lining to cope with the torque introduced. So he literally sits on the longer lever.

On the one hand it is the common, ubiquitous physics and on the other hand the type of lining material that enables a clutch with CR linings to transmit a higher torque with the same pressure force of the springs. The lining sets are suitable for every Cosa 2 coupling. An existing superstrong can also be easily retrofitted or put together yourself.

A CR pad set enables a clean and freely separating clutch with very little lever travel. The lining material also enables very simple and safe switching operations at high speeds. We recommend an oil with the specifications Jaso MA / MA2 or API GL-4 as a lubricant for these clutch linings.

For example that Valvoline 10W40 MA2.

The pad set is available with and without steel washers:

If you are converting a normal Cosa clutch, we also recommend a set of reinforced springs:

BGM8800A - Clutch spring set -BGM PRO XL- Vespa Cosa2 - 8 pieces

BGM8801A - Clutch spring set -BGM PRO XXL- Vespa Cosa2 - 8 pieces

New Lambretta clutch MADE IN GERMANY

The bgm super strong A new family is growing Lambretta clutch.

With the BGM Superstrong coupling for the Lambretta GP and LI models we can now offer you a clutch for your Lambretta with sprockets 46 and 47 teeth.

The scope of delivery includes the complete clutch kit with 6 disks and 10 springs, including the pressure plates for the Lambretta GP and LI / SX gearbox cover.

Lambretta clutch with 6 discs

Clutch linings, steel plates and springs

Lambretta clutch with 10 springs

With the 10 bgm PRO XL springs and the bgm 6-disc clutch linings a very high torque can also be transmitted with a very short reduction ratio from pinion to sprocket: Mathematically up to 60Nm.

By the use of ten feathers you have a lot of options to determine the perfect selection of spring force for your engine.

Chain wheels with 46 and 47 teeth

With the sprockets you have the choice between 46 teeth and 47 teeth.

Due to the very open design, the sprocket remains very light and enough oil can penetrate to the coupling socket at any time.

The flanks of the sprockets are lengthened to give other combinations of clutch linings and steel disks enough space.

Together with the bgm pinions you can put together your own individual gradation depending on the gearbox.

Coupling spider, base plate and cover plate

In order to ensure good operability, the coupling spider, the base plate and the cover plate have been completely reconsidered.

The coupling spider has been lengthened and the flanks have been adapted to the base plate. This guarantees good ease of movement even under high impact loads without the base plate tending to set. This effect is further reinforced by the 10 springs evenly supported.

The overhang of the coupling spider to the chain wheel is a maximum of 0,1mm. By maintaining this low tolerance and by using the BGM coupling socket, clean and good guidance of the sprocket is permanently guaranteed.

Built-in clutch compressor

Practical; the integrated clutch compressor.

With 2 screws you can easily change the pad or spring. Two screws are lighter and easier to stow away than the big brother from the workshop, especially for traveling on longer tours.

Buy Lambretta clutch