35PS +, an ESC-K2 Vespa racing engine is created -PART2-

Vespa racing engine with 35HP + part 2

Today the first part of the innards of the Vespa racing engine is on.

Special requirements call for special solutions.

The crankshaft is subject to very high loads. It has to transmit the pressure generated by the combustion in the cylinder to the drive in a translatory manner and is subject to rapid jumps in engine speed during racing. Our special shaft weighs almost 2000 grams. and is therefore a lot more massive than an already quite officially balanced Polini rotary valve crankshaft with 1400gr.

In direct comparison, a V50 crankshaft weighs just 900 grams. a real flyweight.

The high mass of the crankshaft allows the engine to run very smoothly and is less likely to be disturbed by a rather heavy piston.

However, the rotating heavyweight requires proper storage, after all, with increasing speed, the loads and forces acting on the bearings increase exponentially.

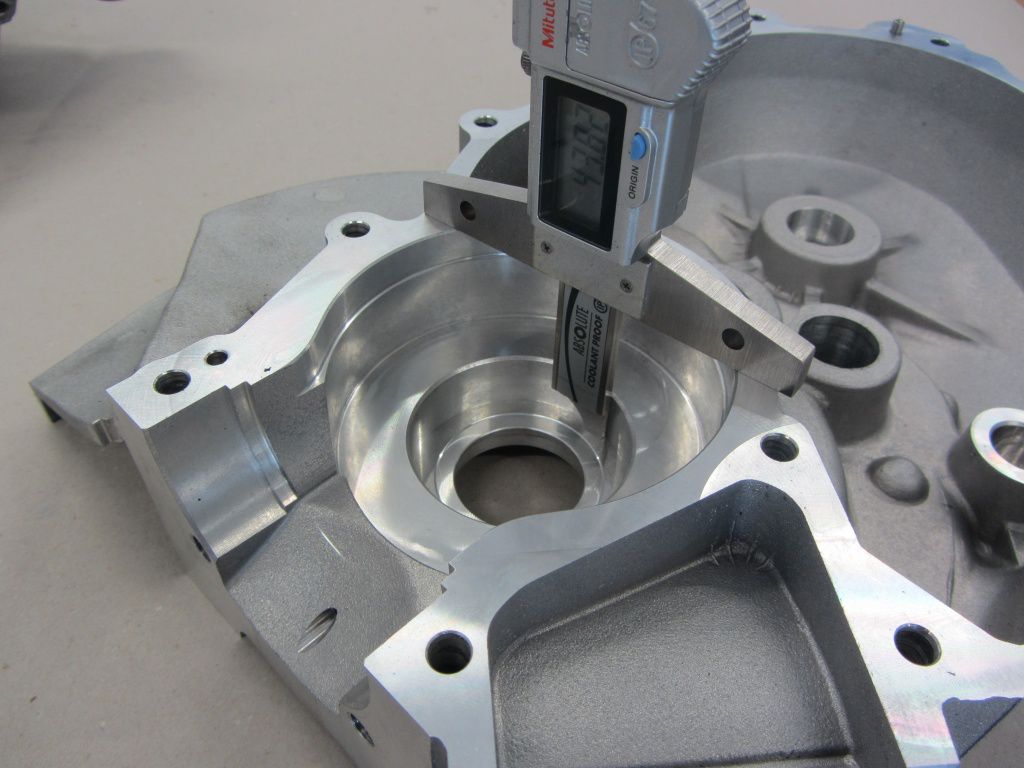

The inner ring of the bearing is used for lateral guidance in the housing. Therefore, the axial play in the housing must be measured in advance for installation.

With a depth gauge, measuring is very easy and accurate. For self-control, we carry out several measurements at different positions in order to avoid a measurement error.

The dimensions of both housing halves add up to an installation width of 78,05mm. We do not need to consider the strength of a housing seal. As is customary with modern assemblies, the Quattrini housing is made without a solid seal and only with Sealant put together.

In order to know before installing the bearing with which thickness of shim rings we need to insert the bearings in the housing, we need the installation dimension of the crankshaft.

The inner rings are shrunk onto the stub shaft. To be on the safe side, if an inner ring should jam during assembly, we fix the crank webs with one more to the crank pin Directional wedge and put one Recoil-free plastic hammer ready.

The crankshaft is with Cooler spray cooled down ...

and which heats the inner rings in the assembly tool.

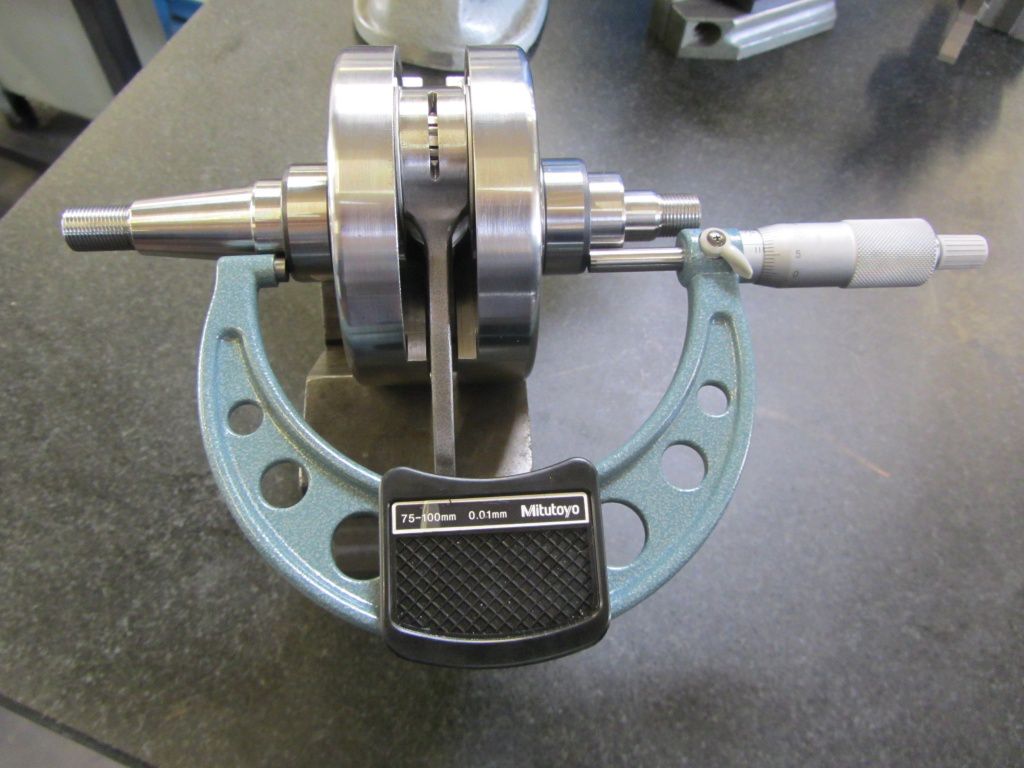

As expected, the heated inner rings fell onto the crankshaft stubs without any problems and we can measure the installation width of the shaft.

The micrometer gives us a dimension of 77,58mm. With a desired installation clearance of 0,20mm - 0,40mm, we need a shim of 0,20mm. With that we end up in the middle of the tolerance field.

In our case we only need to compensate 0,20mm. If the dimension is larger, it is advisable to compensate for the axial play on both sides, as otherwise one-sided pressure load can occur on the connecting rod and connecting rod bearing. In the performance and speed category we strive for, the cornerstone for a reasonable defect ...

All other bearings are also used by shrinking.

At the primary bearing, the 16005 , we consciously choose a bearing with increased internal clearance “C3”.

The bearing fit in the Quattrini housing is in the lower tolerance range, so it is rather tight.

After shrinking, the housing moves back in and increases the pressure on the bearing outer ring. By installing the primary, the inner ring of the bearing is also expanded, which further reduces the bearing clearance. If the bearing clearance is too small, the bearing would run too tight and thus be damaged in a relatively short time.

At the camp for the Main shaft on the wheel side, we use a 6204RSH, i.e. with a one-sided seal.

This means that the brake anchor plate can be removed without losing oil when changing the primary or working on the clutch.

Before the auxiliary shaft and auxiliary shaft bearings go into the engine, we check the installation clearance of the crankshaft.

The simplest method is to control via Feeler gauge.

The crankshaft is simply inserted into the housing and the housing is screwed into the stator housing. Then the shaft is pulled once to the stop on the gear side and measured between the cheek and the flat surface in the housing. The crankshaft is then pulled to the alternator side and the gap is measured again. The resulting difference in dimensions is therefore our installation clearance. In our case the values are 0.70mm and 0,50mm, so the installation clearance is in a healthy range of 0,20mm.

Next we check the seat of the clutch spider on the auxiliary shaft. The cons must fit perfectly so that the force can also be transmitted on this tiny surface.

The contact pattern can be determined very well with valve grinding paste. When the cone is flat, the auxiliary shaft is ready for installation.

The spurious and 6200 we use it together because the installation position is deep in the housing and the small bearing is difficult to handle when loose.

Once the auxiliary shaft has taken place, we can start measuring the clutch.

by Bengt Lange

by Bengt Lange

Leave a Reply

Want to join the discussion?Feel free to Contribute!