Polini 210, BGM 60mm, Dellorto SI26 - test engine part 5

Only a few more steps separate us from hooking the engine into a test vehicle.

As a test victim for our Polini engine, we use the familiar one Silver Fern .

When assembling the pole wheel, make sure that the groove is the Crescent wedge hits exactly.

Then the Flywheel nut tightened with 65Nm. washer do not forget !

The rear one brake drum is initially only attached and fixed with the nut.

As soon as the rear brake is functional, the brake drum can be attached with 110Nm. Fuse cage and split pin must of course not be missing.

We still connect the controls on the handlebars to the engine, that is Gas-, switching and Clutch will attached and adjusted.

The security game on clutch lever should be between 1,5mm and 2mm in order to avoid the clutch cable being actuated when shifting into higher gears and thus the Pressure mushroom on the pressure plate works and the Clutch possibly even actuated.

Olive oil and fuel hose follow. The air bubble in the oil hose is intentional. When connecting for the first time, you can check whether the oil is being pumped into the carburettor.

However, the air bubble should not be larger than shown here, otherwise there is a risk that the pump will run empty and no more oil will be transported towards the carburetor.

For the “first firing” we fill the tank with 1 liter of super in a mixture of 1:50. This amount of fuel should be enough to bridge the gap until the oil pump delivers the valuable lubricant.

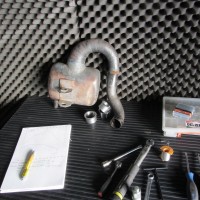

The last missing parts are the Flywheel and the Cylinder hood.

Then it's fire free!

After warming up for a few minutes, we first shift through all gears once and test whether all gears hold and the clutch disengages properly.

A quick look at the oil hose reveals - the pump is running.

So then, first attempt on the test bench with the following setup:

- Polini 210, Outlet, piston and overflow channels are not machined, Spacer cylinder base 1mm.

-YES 26, Cosa float chamber ceilingl with additional bore, nozzle holder also with additional bore

- Nozzles 48/160 - 160-BE3-a set Main jets to play around

-Inlet area freed from the disturbing edges, the seals adapted to the new contour. Polini velocity stacks with adapter and Polini air filter.

To be on the safe side, we check them Ignition adjustment by reversal measurement. If the tolerances on the crankshaft, pole wheel and base plate are correct, the markings should be on top of each other when flashing. This time we made the 18 ° marking on the pole wheel.

Ok, the ignition is correct - then nothing stands in the way of the first test run ...

Leave a Reply

Want to join the discussion?Feel free to Contribute!