the last chance to get the classic retro mirror for left side mounting

In your Scooter Center Shop you will find a large selection Spiegel and Auch Clamp mirror for the leg shield!

But do the mirrors fit your scooter? What is the size how does the color fit? What shape do the clamp mirrors have and what are the proportions in relation to the leg shield?

We have now installed all clip-on mirrors, also photographed from different perspectives! Now find your leg shield clamp mirror from a large one Selection in our shop.

All legshield clamp mirrors at a glance

Mirror BUMM chrome, stainless steel, leg shield clamp mirror small

The classic clip-on mirror in kidney shape from BUMM for Vespa and Lambretta with a small mirror glass.

Trapezoidal shape. Visually very discreet and easy to adjust thanks to the universal mounting option on the leg shield.

This classic is available for:

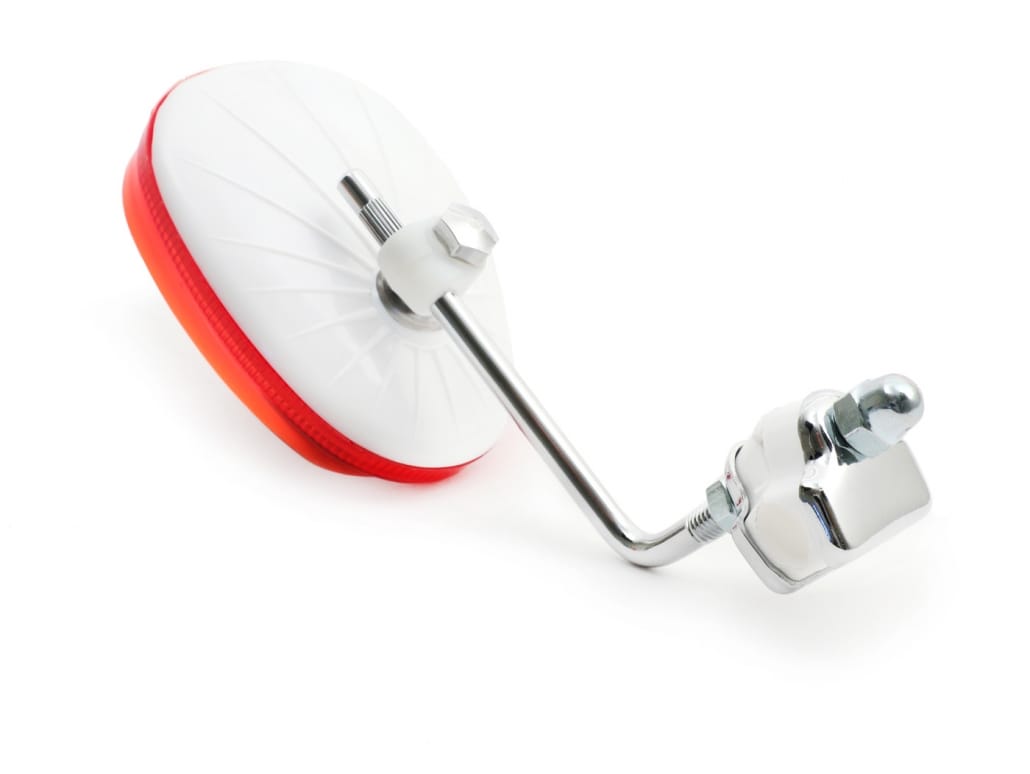

Mirror BUMM retro leg shield clip-on mirror, colored plastic housing

Universal fitting retro clip-on mirror for classic scooters, mopeds, mopeds. The kidney mirror is Made in Germany by BUMM. Neatly processed mirror in trapezoidal shape with white plastic housing and colored, transparent edge.

Has a plastic housing with a ball head. The clamp is suitable for both round slotted tubes and bead profiles (standard on Vespa).

| Article no.: | Design |

|---|---|

| 1050138 | White, blue, left |

| 1050141 | White, blue, right |

| 1050139 | White, orange, left |

| 1050142 | White, orange, right |

| 1050137 | White, red, left |

| 1050140 | White, red, right |

Mirror FAR leg shield clamp mirror round Ø = 105mm - E3 (E-mark)

Beautiful mirror from FAR in a circular shape and a diameter of 105mm. Available in chrome and black. The leg shield mirror has an E-mark (E3).

This round FAR mirror is available in:

Mirror FAR leg shield clamp mirror trapezoidal

This is a nice alternative to the round mirror from FAR. The trapezoidal FAR chrome mirrors are attached to the leg shield with a screw clamp.

Small grub screws also fix the mirror securely to the edge protection of the leg shield or a slotted tube. The mirror rod is adjustable, the mirror itself can also be slid on the rod and tilted. by means of a ball head.

The mirror is available for the left or right side as well as chrome-plated or in black!

Mirror SKY leg shield clamp mirror chrome round Ø = 105mm

Beautiful, classic round mirror to clamp on the leg shield.

The chrome-plated mirror is fixed with two clamps.

The solid aluminum clamp is ideal for attaching the mirror to the slotted tube of the leg shield. Thanks to the multiple alignment options, the mirror is always quickly brought into the correct position. The stylish cap nuts always clamp the mirror securely and tightly, while the clamp on the mirror body is cushioned in a rubber. The mirror diameter is approx. 10cm, the mirror surface is convex (curved outwards) and thus creates a wide angle. Thus, despite the relatively small mirror surface, a large field of vision can be covered.

Mirror SKY leg shield clamp mirror chrome rectangular 105 x 70mm

The SKY mirror is also available in the angular version: A very beautiful, classic rectangular mirror that can be clamped to the leg shield.

The chrome-plated clamp mirror is fixed with two clamps.

The massive aluminum clamp is ideal for attaching the mirror to the slit tube of the leg shield. Thanks to the multiple alignment options, the mirror is always quickly brought into the correct position. The pretty cap nuts always clamp the mirror securely and tightly, while the clamp is cushioned in a rubber on the mirror body. The mirror dimensions are about 10 x 6 cm, the mirror surface is not so convex compared to our SKY round mirror.

Mirror STADIUM leg shield clip-on mirror, chrome, rectangular

STADIUM mirror MADE IN ENGLAND direct from Caerphilly, Wales, UK.

A real British classic with a long tradition. These legendary clip-on mirrors are made of high-gloss polished stainless steel in top quality and heavy duty. The customers who have consistently rated the mirror at our sim shop top so far, praise the quality and stability of this mirror. Below you can also find a round version of the stadium mirror.

| Article no.: | Position |

|---|---|

| 7675864 | right-wing |

| 7675863 | left-wing |

Mirror STADIUM leg shield clip-on mirror, chrome, round

Round version of the stadium mirror approx. 100mm in diameter. A real British classic with a long tradition. These legendary clip-on mirrors are made of high-gloss polished stainless steel in top quality and heavy duty. Our customers have so far only rated this mirror positively and love the good adjustability, the optics and the quality of the mirror. Angular version like this

| Article no.: | Position |

|---|---|

| 7675940 | right-wing |

| 7675939 | left-wing |

Mirror -VICMA leg shield clip-on mirror- chrome

This inexpensive mirror with a top price-performance ratio from VICMA is available from us in 2 sizes and for left and right: 80mm and 105mm, the large 105mm version also has an E-mark.

| Article no.: | PAGE & SIZE |

|---|---|

| 7676653 | right Ø = 80mm |

| 7676656 | right Ø = 105m |

| 7675853 | left Ø = 80mm |

| 7675854 | left Ø = 105mm |

Information about Spiegel and the StVZO in Germany

Do i need a mirror on my scooter?

According to StVZO §56, every motor vehicle in Germany, which also includes mopeds, needs at least one mirror attached to the left side of the vehicle.

How many mirrors do I need on my scooter?

The number of mirrors depends on the first registration (EZ):

- EZ before 01.01.1990 1 mirror on the left

- Single room from 01.01.1990 up to 100 km / h 1 mirror on the left

- Single from 01.01.1990 over 100 km / h 2 mirrors

How big does the mirror on my scooter have to be?

The size of the reflective surface must be

- before EZ 17.06.2003 at least 60cm² (with round mirrors the diameter greater than or equal to 88 mm)

- according to EZ 17.6.2003 at least 69cm² (with round mirrors the diameter greater than or equal to 94 mm)

be.

Do mirrors on my scooter require a certification mark?

Marked mirrors automatically meet all of the above conditions.

- For vehicles that are approved according to EC law (from October 01.10.2005st, XNUMX) mirrors with certification marks must be installed.

- Vehicles with ABE approval (before October 01.10.2005st, XNUMX) only have to use mirrors that meet the above criteria.