A continuación mostramos el correcto montaje de los neumaticos, como ejemplo usaremos el Neumatico bgm Classic

1. Disminucion of the friction

La cámara interna está expuesta a la fricción al rodar el neumático, por lo que tiene sentido reducir this fricción con Talc. Esto reduce su desgaste.

It distributes a pequeña cantidad de talco dentro del neumático y la recámara se infla un poco, espolvoreándola también un poco.

2. Compare the direction

Antes del montaje de la cámara compruebe si el neumático tiene una dirección de rotación especificada por el fabricante. En nuestros Neumaticos bgm Classic It must be with a flecha that apunta the direction of rodamiento cuando se conduce.

Luego se inserta la camera para que coincida con lado de rotación del neumático, de modo que la válvula típica de Vespa apunte hacia el lado izquierdo en la dorección de desplazamiento.

3. Assembly

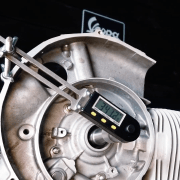

Para el montaje de los neumáticos en los rines / llantas, la Pasta de Montaje será de gran ayuda. Esto permite que el neumático se desplace sobre la llanta / rin, logrando que atornillar las dos piezas sea mucho más fácil

Primero se inserta la válvula a través de la mitad de la llanta / rin ancho y luego se empuja dentro del neumático. La mitad del delgada, también tiene un espacio libre a través del cual se puede acceder a la válvula, al insertarla, asegúrese de que el espacio libre para la válvula sea congruente con el de la mitad ancha ..

Our Llanta / rin bgm tienen pernos intercambiables, los cuadrados seran los que le indicaran donde atornillar, evitando la rotación del tornillo.

Las 5 tuercas de la llanta / rin se atornillan en cruz con un torque de 16-18 Nm. Al fijar, asegurese de que la Camera no question of atrapada between the mitades del border.

Finalmente infle el neumático a 2 bar y verifique que el neumático y la válvula estén correctamente asentados en la llanta / rin.

and ready!

Music: Rene Winkler from SC / NXT Level Amount: First one dub 4