35PS +, an ESC-K2 Vespa racing engine is created

Vespa racing engine with 35HP +

The racing season is approaching with giant strides. Only a few weeks until the first ESC race begin.

You can find information about all classes and the ESC racing series at www.eurochallenge.de

Our Vespa racing engine is used in class 2, the premier class of the Euro Scooter Challenge.

In this class there is practically only a displacement limitation of <150ccm as a regulation.

The top units in this class produce between 35HP and 38HP

Therefore, in most cases you will find a stroke / bore combination of 53/60, which results in 149,85ccm.

In our case, too, we pay for our Vespa engine Falc cylinder with 60 mm bore and a special crankshaft with 53mm stroke, suitable for the Quattrini motor housing, for use.

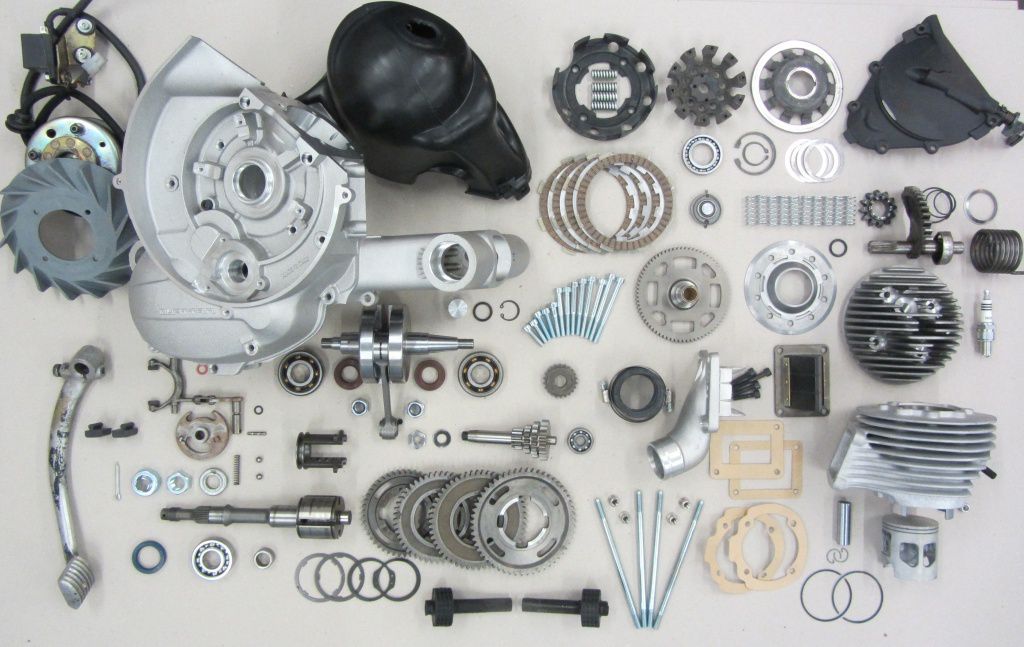

So that you can get an overview of which parts can be used in such an engine, we first laid everything out nicely ...

... and wrote you a shopping list on which you can find all the items you usually need.

This CSV file you can simply upload it to our online shop and then take a close look at all the items in your shopping cart.

We are only now taking a closer look at the motor housing. In the performance range we strive for, even small mistakes can have devastating effects. Therefore, each individual part should be carefully checked before assembly. Especially when partially used parts are used, as in our case, because proven ones can of course be used again as long as the parts are in good condition.

In the case of the motor housing, we first check all sealing surfaces and bearing seats.

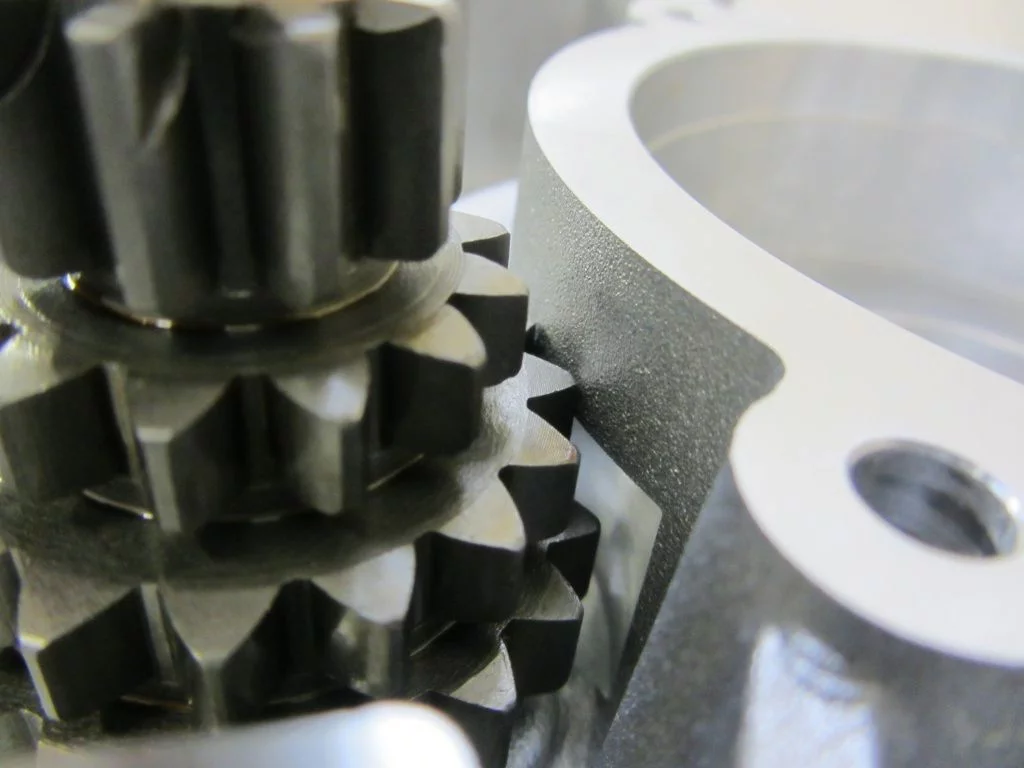

In the area of action the spurious if a franking is noticed ...

Here it would be included in the later installation Warehouse get into trouble. Later on, on the racetrack, this can lead to further problems if a different gear ratio should be necessary due to the route profile.

So we have to rework the undercut so that the auxiliary shaft can simply be pulled out of the bearing and against a longer translated version lets swap.

Furthermore, there are no more special features in the transmission.

The “small” half of the case, however, still has a problem.

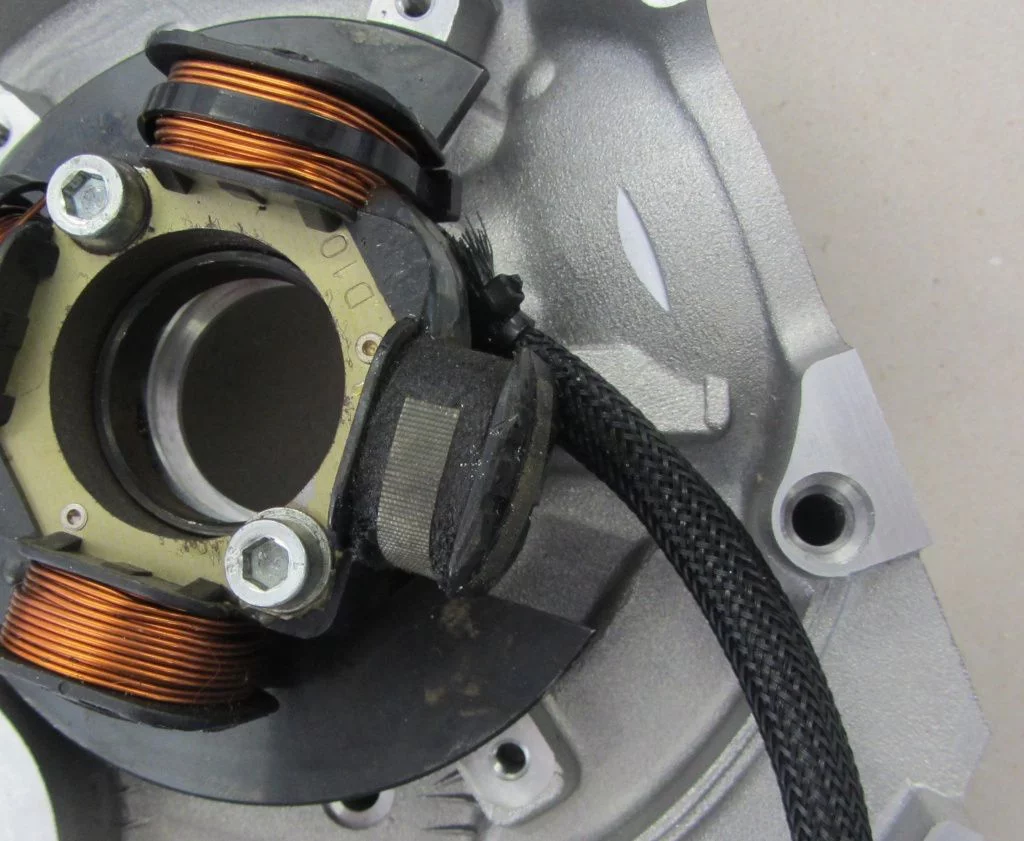

Normally you simply screw the stator the ignition tight, fumble the cables and ... uh ..

you definitely don't get one here Cable branch of the stator out of the danger area of the rotor.

Since we unfortunately cannot provide a WiFi ignition in the short time, a suitable outlet must be created.

It is important that you do not drill randomly anywhere into the housing and create additional, unsuitable ventilation holes.

You should also make sure that the cable branch is still held down by the stator plate in order to avoid really abrasive contact with the rotor.

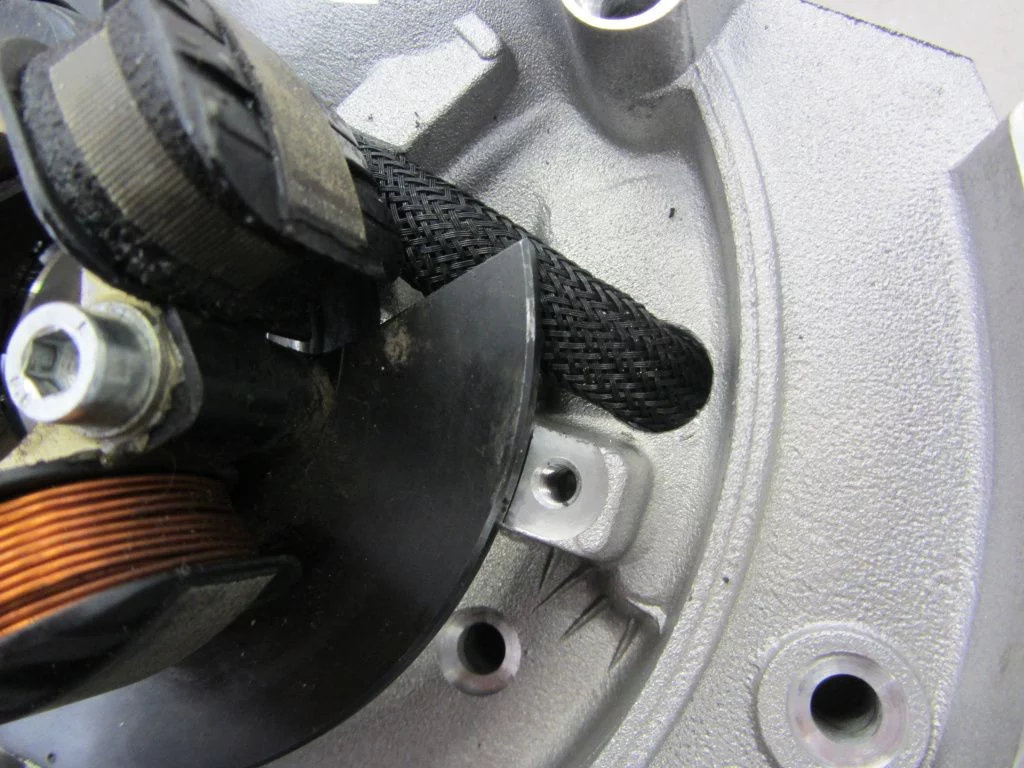

For the sake of simplicity, we use one as protection in the implementation Rubber grommet of the V50.

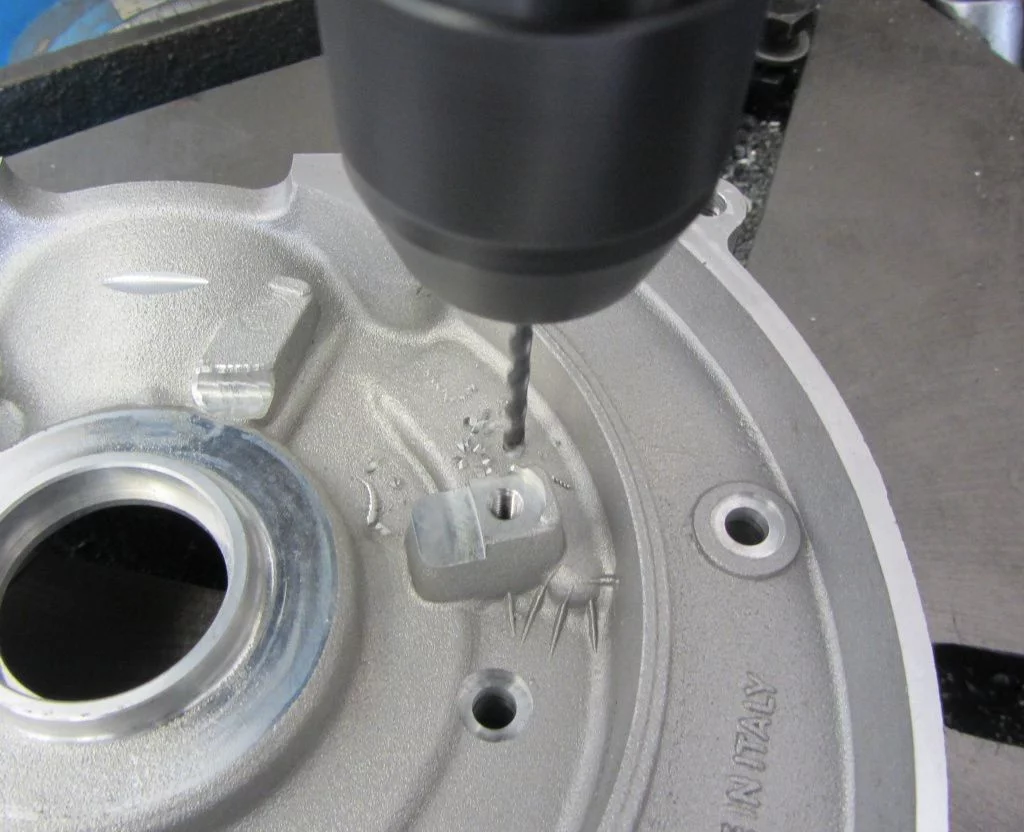

The appropriate hole for this is 12,5mm.

Holes over a diameter of 10mm should always be pre-drilled smaller.

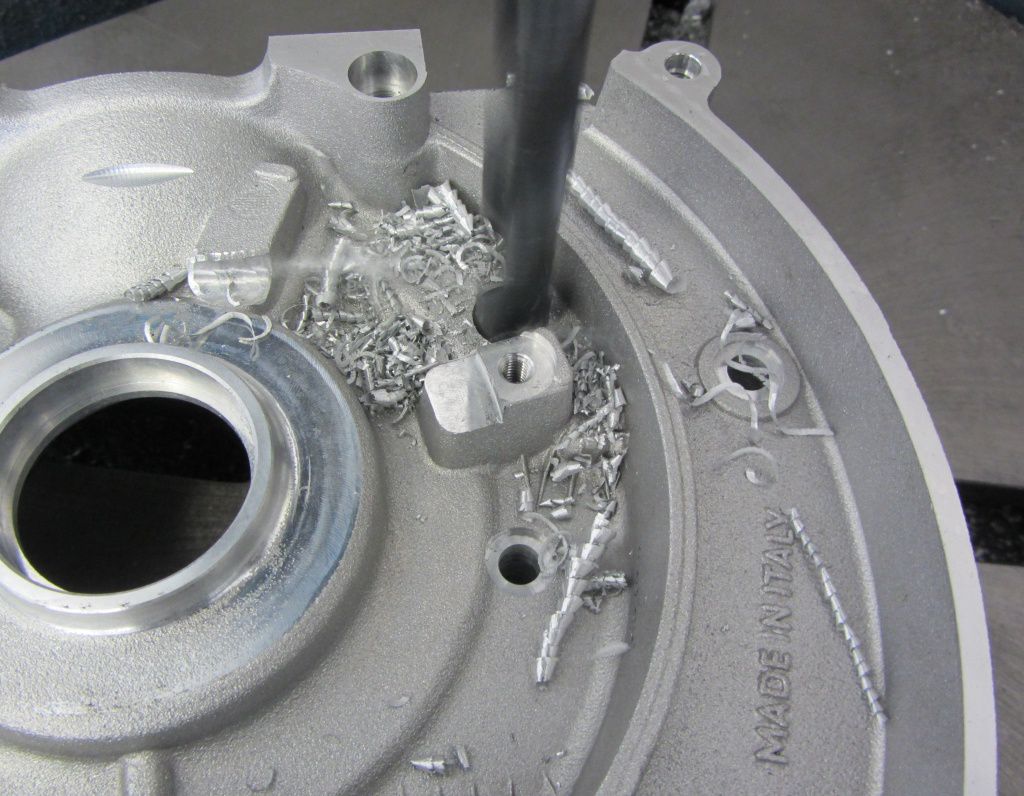

... and then bring it to the desired level.

Deburr the hole and try it on briefly.

All fine. The small half of the case is done with the rough adjustments.

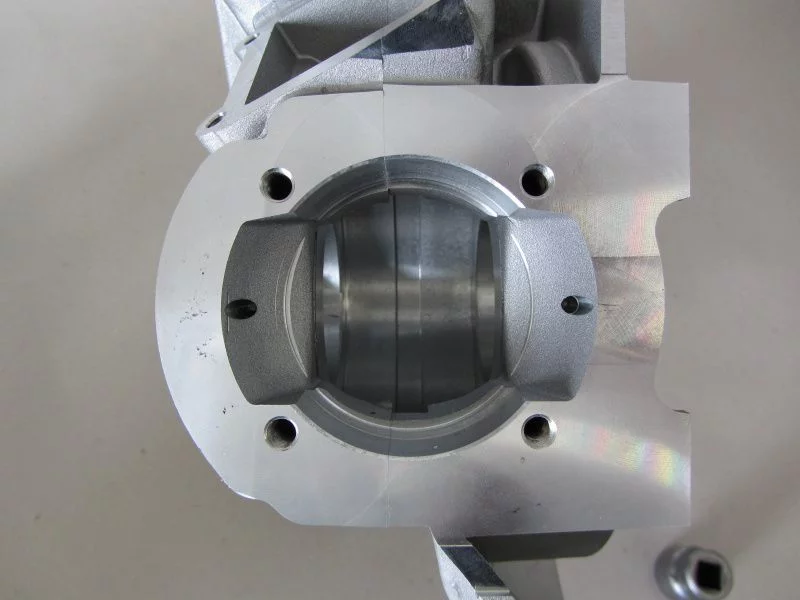

Next, the area of the cylinder base comes into the focus of our assessment.

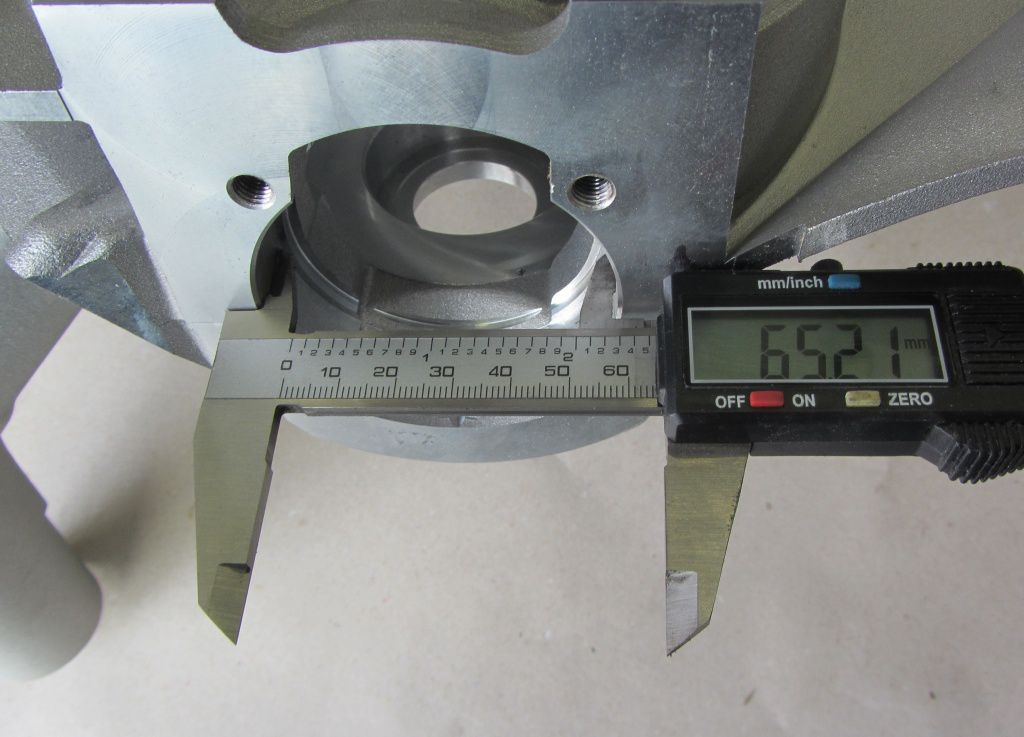

The Falc cylinders are manufactured with a cylinder base diameter of 66,5mm. Of course, Mr. Quattrini designed his motor housing for a diameter of 65,2mm, just to match his cylinders.

This results in two possible options:

1. The motor housing can be spindled to the appropriate cylinder base diameter

2. The cylinder base of the Falcen is given a new outer diameter

We choose option number two.

So if you wanted to go back to one at some point other cylinder turn around, all options remain open. The wall thickness of the cylinder base is completely sufficient for this step.

Turned off briefly, the cylinder can be held in the housing for a test to determine the extent to which the processing of the overflow channels still requires.

Almost perfect, we only have to rework the outer edges of the channel in the cylinder. The case remains untouched at this point. We make the necessary changes after determining the control angle on the cylinder.

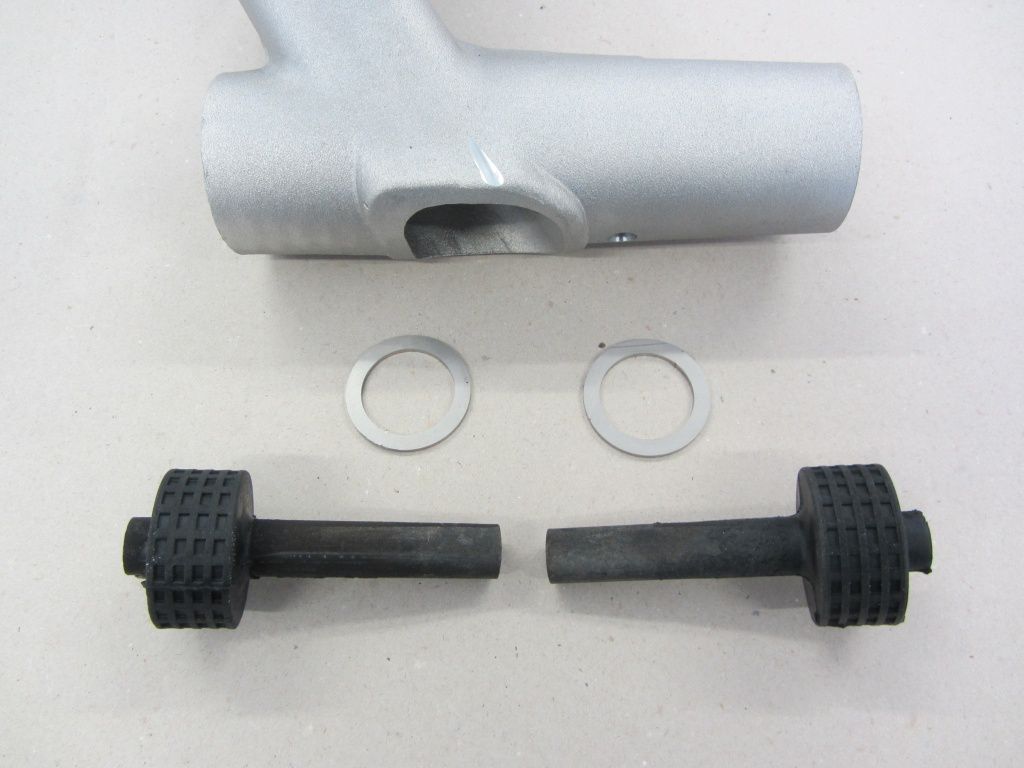

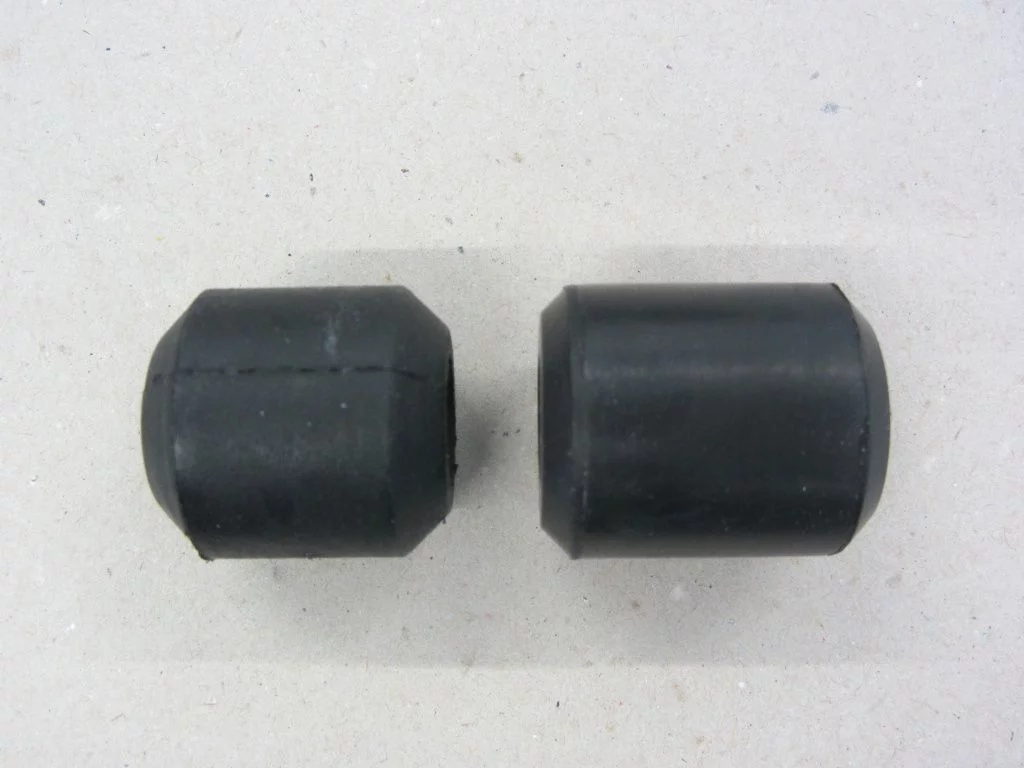

The motor housing is delivered without silent rubbers. There are some more or less sensible solutions for the traverse available on the market. Personal preferences also play a role in racing. The rubbers shouldn't be too hard. “Blocks” with more than 70 Shore hardness are certainly justifiable for fast straight-ahead driving, but as soon as you start doing gymnastics exercises on the scooter to quickly circle the bullet around the curves on a kart track, the requirements are more like the rest of the chassis: “as hard as necessary, as soft as possible ”.

Therefore, in our case, we use the Silent rubbers of the V50 / Primavera Models with approx. 50 Shore hardness.

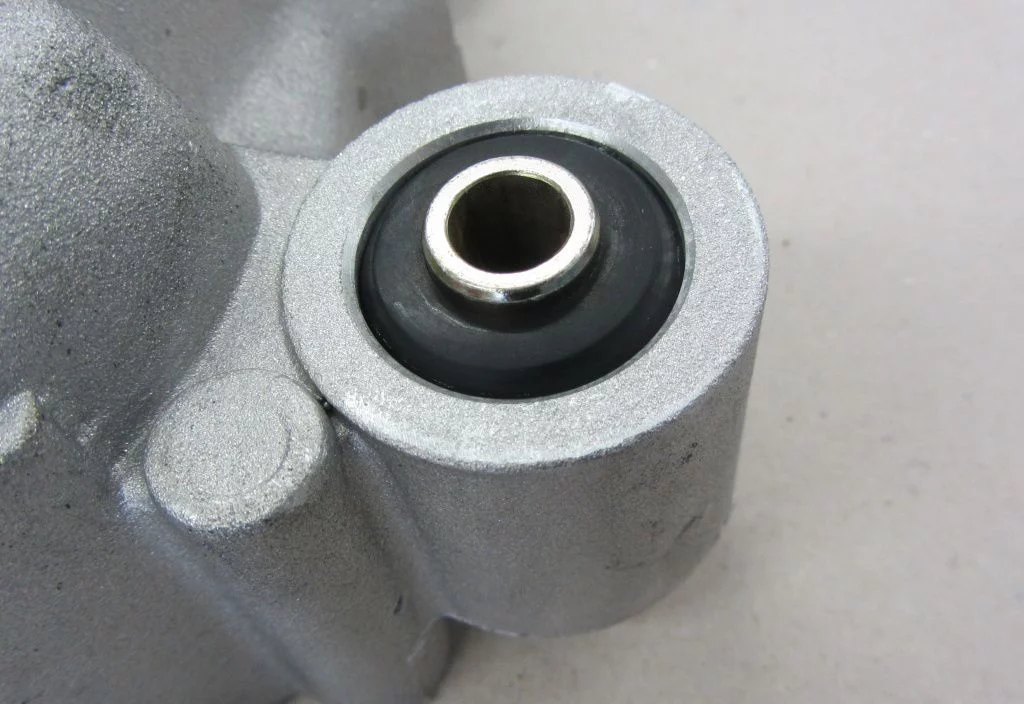

On closer inspection of the traverse holes, it is noticeable that the stops for the silent rubbers turn out to be rather small. In order to avoid that the rubbers slowly walk into the bore with the high lateral forces and the housing can begin to move sideways, we use the additional stops from the PK models.

Here is the small stop surface ...

The stop ring of the PK is simply inserted and afterwards, when installed, is fixed by the silent rubbers.

The soft truss rubbers can be moved relatively easily with talc or a little Montagepaste used.

“He who is lazy is also clever”; therefore we leave the slightly strenuous work to the workshop press. In an emergency, the two-part silent rubbers can also be easily replaced by hand.

For the rear mount for the shock absorber, we use our own silent rubbers with the original case.

Compared to the Piaggio rubbers make our silent rubbers laid out a little wider ...

and in the assembled state they are flush with the shock absorber eye on both sides. This gives you better lateral support.

The next post is about installing the ball bearings and calibrating the crankshaft ...

by Bengt Lange

by Bengt Lange

Nice documentary!

Does the depth for the silent rubbers on your Quattrini case fit?

Hello Stefan, Quattrini typically leaves a small gap of approx. 2mm at the joint of the two silent rubbers. The housing can be installed in the frame without any problems.

Hello Alex!

When will you go on with the engine?

I'm really excited ...

gruß

Jens

when will you continue?