Our test engine ran warm and the spraying with a secondary nozzle 48/160, air correction nozzle 160, mixing tube BE3 and a main nozzle of 140 seems to work for now. Now we can do the first runs to measure performance.

To do this, the overall ratio in 3rd gear is measured 2-3 times on the P4. In our case, the overall ratio is 3,21. We can re-enter this value manually in later runs in order to eliminate errors when measuring and to obtain consistent, reproducible results.

So we do the first 3 runs. If all runs are almost congruent, we can assume that the experiment worked well and that we “experienced” a comparable result.

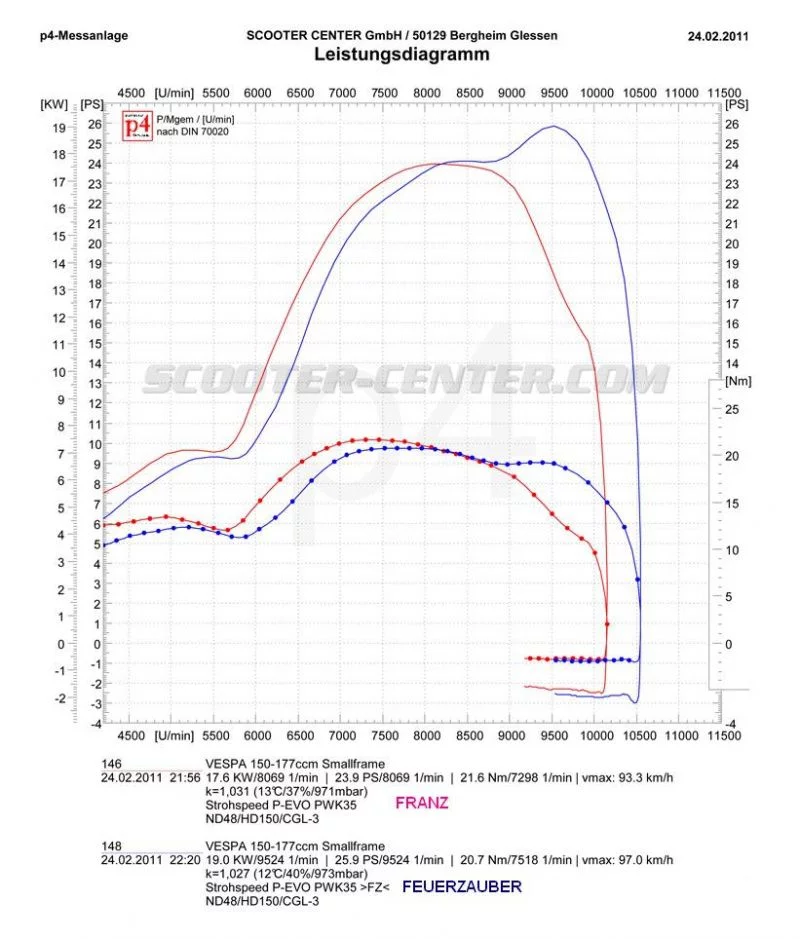

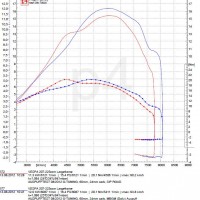

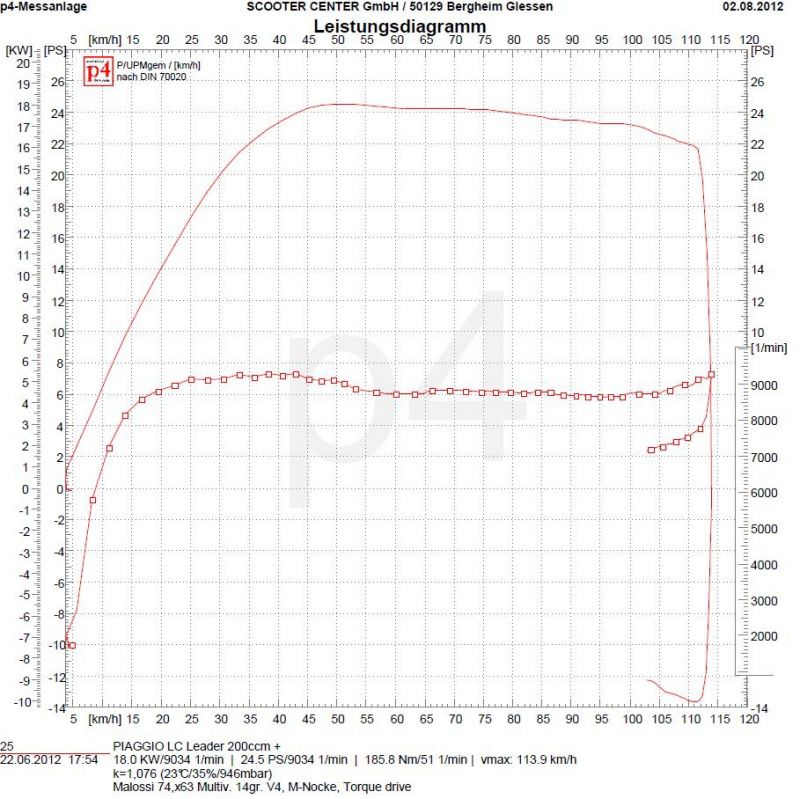

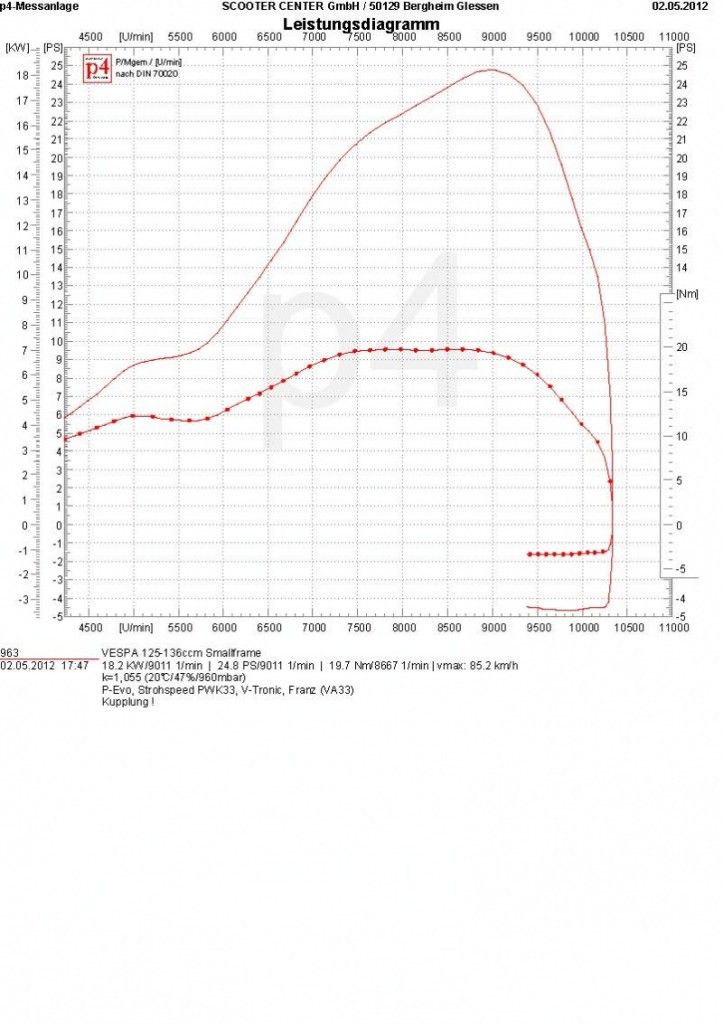

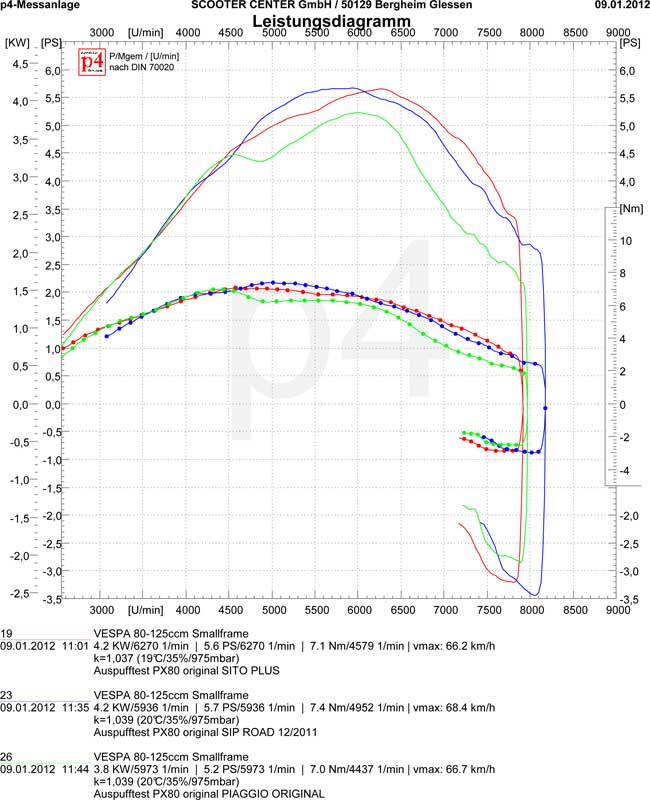

Here is the first result.

It's nice to see that, as expected, the engine makes a lot of torque available very early on. This impression is also confirmed during a test drive on the road. In terms of the tractor, the engine pushes off very nicely at 3500 rpm, i.e. practically at increased idling speed, with 17 Nm.

Besides, the unobtrusive suction noise of the Polini solution is pleasing. With the adapter, Polini has incorporated a small but important trick. The sound waves break effectively on the inner edge of the adapter and thus become a sonorous, inconspicuous suction noise.

Back on the test bench, we mount the MMW cylinder head on our 210 Polini.

For the tests on the test bench, we put a 0,5mm and 0,2mm thick Polini cylinder head gasket under it so that we get a comparable squeeze dimension of 1,70mm. It is absolutely advisable not to underlay an O-ring sealed cylinder head with an additional gasket. The material of the solid seal could be pressed into the O-ring groove by the surface pressure in connection with the thermal load on the cylinder head, damage it and thus render it unusable.

For test purposes, however, this is possible without any problems, after all we are not planning a circumnavigation of the world but a series of tests. Should the shape of the combustion chamber of the MMW cylinder head prove to be useful, we can think about a necessary change at this point.

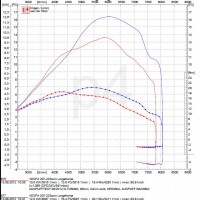

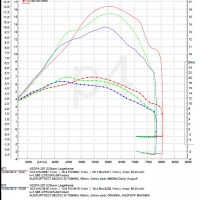

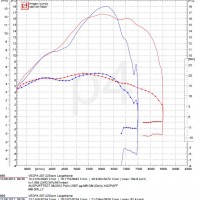

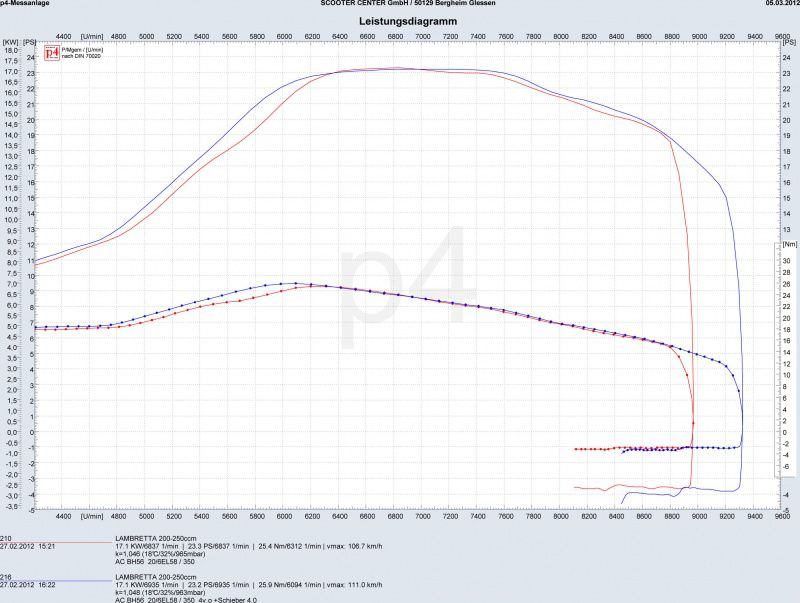

After 3 more runs we get the following nice, colorful mountain range in direct comparison.

RED: MMW

BLUE: Worb5

The extra power of the MMW cylinder head results on the one hand from the slightly higher compression and most likely from the different combustion chamber geometry compared to the Worb5 cylinder head. Since we both brought the cylinder heads designed for a 57mm stroke to the same crush dimension of 1,7mm, one can speak of a fair comparison here.

The maximum torque is as usual at 4700rpm and increases with the MMW cylinder head to a whopping 22Nm.

At 7000rpm there are still 17PS and 17Nm. Certainly good to achieve an average high travel speed.

We save ourselves the experiment with the MMW cylinder head for 60mm stroke. Not out of laziness, but because we already know that the engine responds positively to a little more compression.

Because with the same combustion chamber geometry, but with the compression reduced due to the larger crush dimension, no increase in output or torque is to be expected.

A little more band with higher torque and more power in the higher speed range would be desirable. This would enable us to better overcome the exponentially growing driving resistance with increasing speed.

Mmmmh, what else could you try now? Actually already suffering at a high level? After all, we are talking about an engine which, thanks to its well-considered selection of components and its assembly, provides quite a remarkable performance.

With a look through the test stand room, we discover our test prototype of the bgm bigbox -

we should still try that.

Tomorrow… (: