Posts

Before the Lambretta BARRACUDA was Vespa EL-SIDNEY

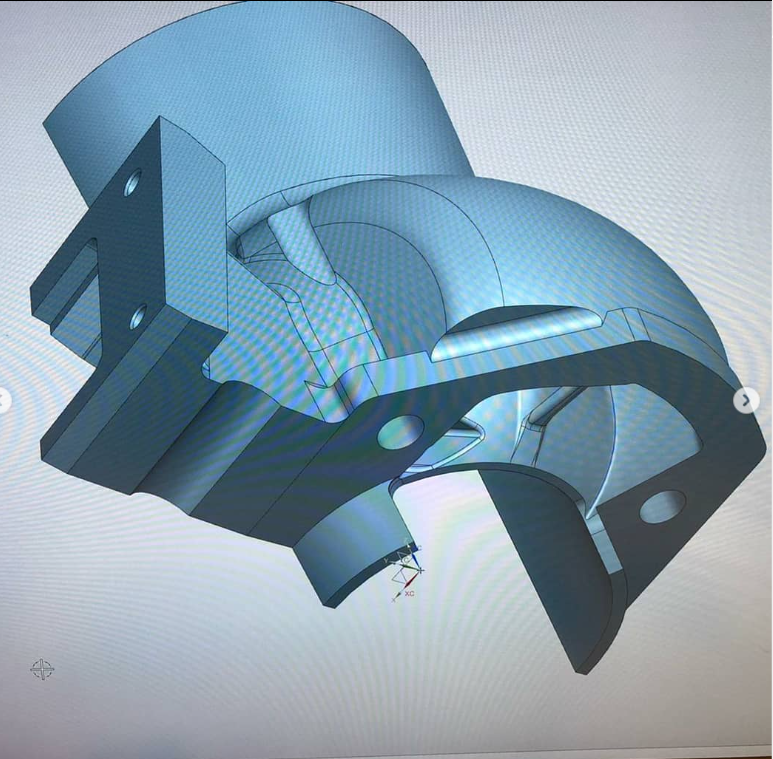

A previous project by Felix is the Vespa PX “EL-SIDNEY”. This scooter tells a story: it was the first Vespa with a CNC engine.

The Vespa PX EL-SIDEY has been the development vehicle for various developments since May 2006, not least for the one that is available today Vespa CNC motor from GP-ONE and KR-Automation GmbH, as we do in our Vespa Smallframe demonstrator XI GENERATION have installed.

Of course, the scooter was also in various newspapers and magazines such as Scooterring, Rollerjornal, etc.

With this Vespa PX, Felix has won some “Best Engineering” awards and has also proven in practice on quartermiles what the scooter is capable of via 50PS plugged. As is currently the case in the new Lambretta project, that brought it bgm PRO chassis Even with the Vespa, the 50PS is safe on the road.

Engine:

- 38mm Keihin carburetor

- V-Force membrane

- Rotax 248cc cylinder

- 61mm KR CNC crankshaft

- S&S coupling

- KR CNC gearbox

- S&S wide tire kit

- 120/90 rear tires

- KR CNC engine block with support of the main shaft with 3rd ball bearing

- Exhaust in-house development with Viton flange after the manifold and suitable right hand routing

- Silent bushes from ClaussStudio

- Adapted MVT ignition

Frame and chassis:

- Stainless steel pipe in the hatch

- Fully hydraulic disc brake on the front wheel

- Jaws widened by 40mm on each side (gills on spare wheel cheek made of carbon fiber)

- Carbon fiber spoiler with a satin finish, tested twice in the wind tunnel of the University of Stuttgart

- Chassis bgm PRO

- Short-stroke throttle

- Speedometer SIP

- Exhaust gas temperature measurement Stage6

- Clear glass turn signals

- Xenon headlights dipped beam

- High beam halogen

- Taillight LED

- Harley tank in the passage (rotated and modified)

- Water cooler (KTm Duke) arranged under the side hood in a V-shape.

- 2pcs. SPAL fan can be switched on separately if necessary

The Lambretta BARRACUDA story

Why “BARRACUDA”?

BARRACUDA Lambretta on the Scooter Center custom show

Tickets in pre sales or at the box office / Info.

Website Barracuda Lambretta

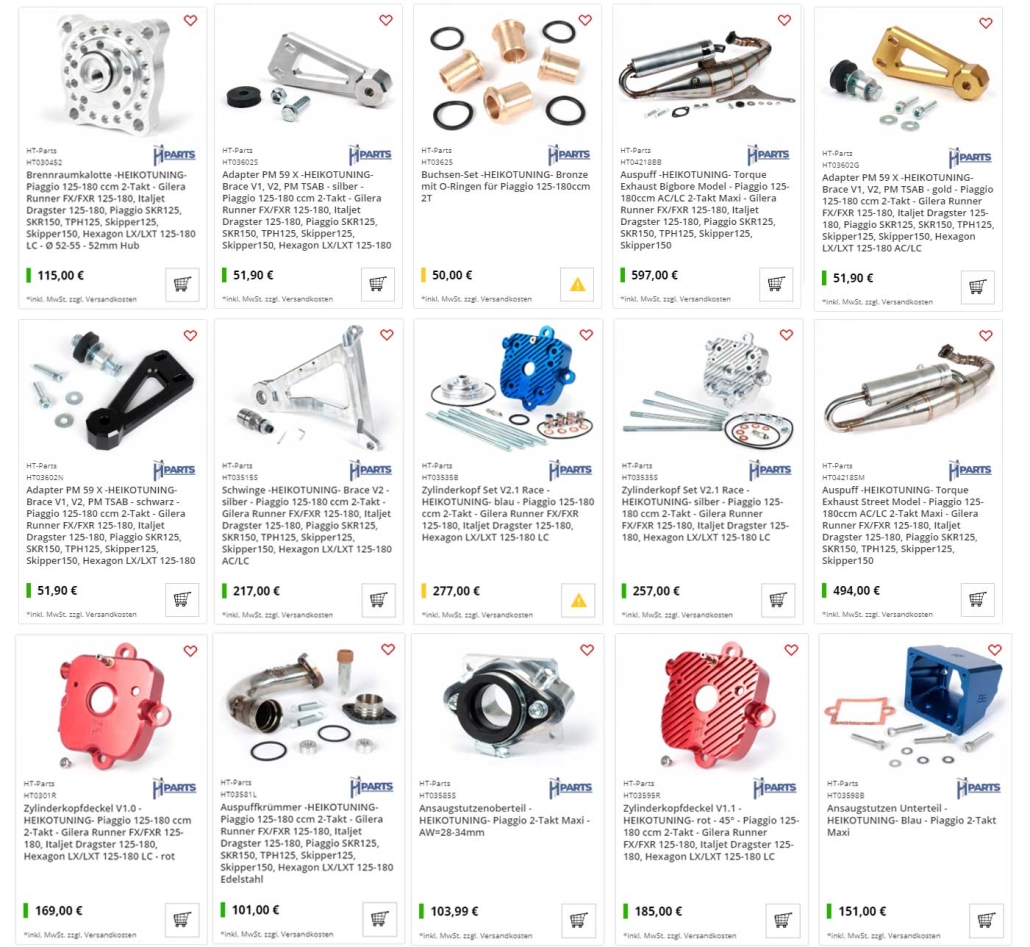

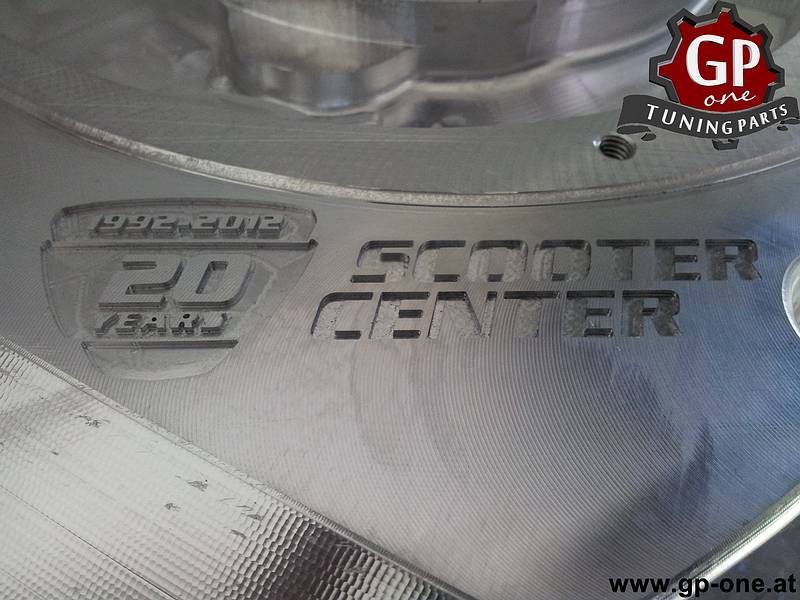

Vespa Smallframe Motor housing reduced

We currently have the high-end Vespa Smallframe GP One motor housing reduced by 33%.

The one milled from the full block of aluminum Vespa Smallframe Motor housing for Vespa V50, PV125, ET3, PK50, PK80, PK125 etc. can also cope with the massive loads of modern cylinder generation such as Falc 153cc or Parmakit W-Force.

Save over 490 euros nowGP One Tuning Parts - Finest Austrian Vespa Tuning

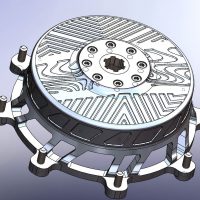

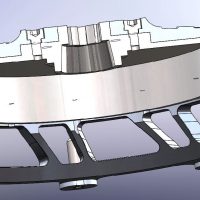

GP One Tuning Parts develops CNC milled products made of high-strength materials that stand out from the crowd. The Austrians have to rely on the Development of tuning articles Specialized for 2 - stroke Vespa scooters. Unique, CNC milled engine components of the highest quality that individualize your Classic Vespa.

Custom CNC motor housing

We also have in our custom Vespa Vespa Smallframe Generation XI demonstrator the motor housing installed:

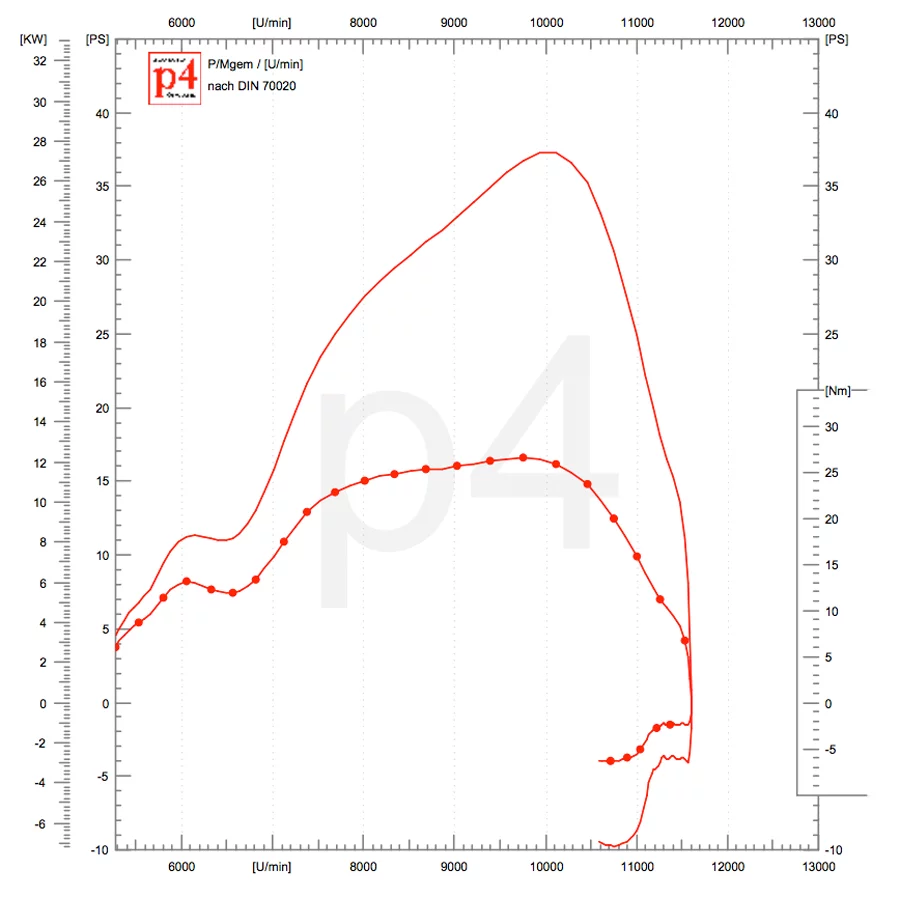

Motor housing also good for 37HP +

GP One has published quite spectacular performance graphs achieved with your engine cases.

Here as a PDF: Vespa performance diagram_Falc_154 _-_ 37_3_PS

Motor housing -GP ONE CNC- Vespa V50, V90, SS50, SS90, V50 SR, PV125, ET3, PK50 S / XL, PK50 S / XL, PK80 S / XL, PK125 S / XL, PK125 ETS - Ø foot / Ø cheeks = crank webs Ø = 88.0mm

Article no. 7674577

Milled from a full block of aluminum Motor housing for Vespa V50, PV125, ET3, PK50, PK80, PK125 etc.

The housing manufactured by GP One from Austria is also able to withstand the massive loads of the modern cylinder generation such as falc 153cc or Parmakit W Force gewachs that.

Save over 490 euros nowThe solution for powerful engines

Original motor housing: In order to be able to install this cylinder class with a 60mm bore, it is necessary to make modifications to the series housing, whereby the wall becomes very thin in some places. In the case of very powerful engines, cylinder base mountings were already torn off.

GP One motor housing: Gernot Penn's case, on the other hand, is bulletproof. There is enough solid aluminum everywhere and some clever detail improvements are also included in the engines well over 30hp a secure base on the rear wheel.

Now with us in Scootershop order:

We were really happy again, the Seven7 parts from Austria have finally arrived. You can find an overview of the available products under this LINK.

We were really happy again, the Seven7 parts from Austria have finally arrived. You can find an overview of the available products under this LINK.

All parts have been tested in practice by the Lambretta driver for the Lambretta driver. Martin has invested countless hours in developing and improving his parts. He approached the production just as meticulously. He did not shy away from using a 5-axis CNC milling machine. The result is perfect parts that do not require any rework and are manufactured to zero. It couldn't be better!