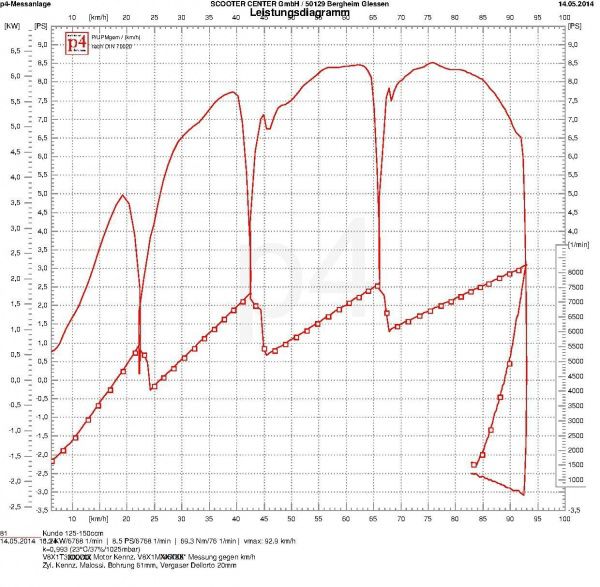

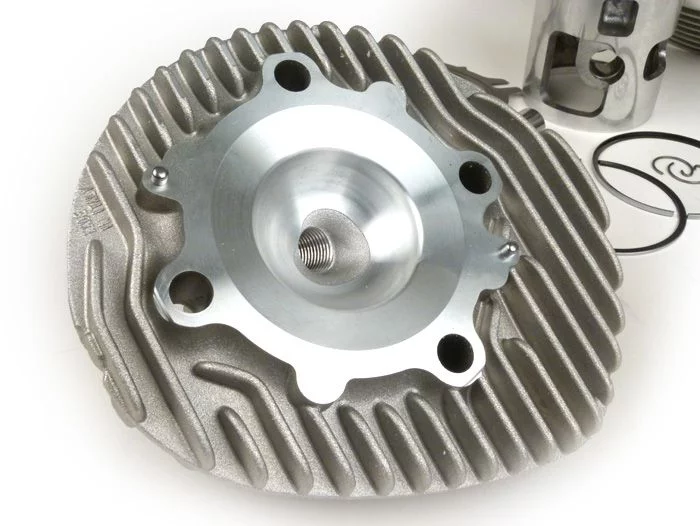

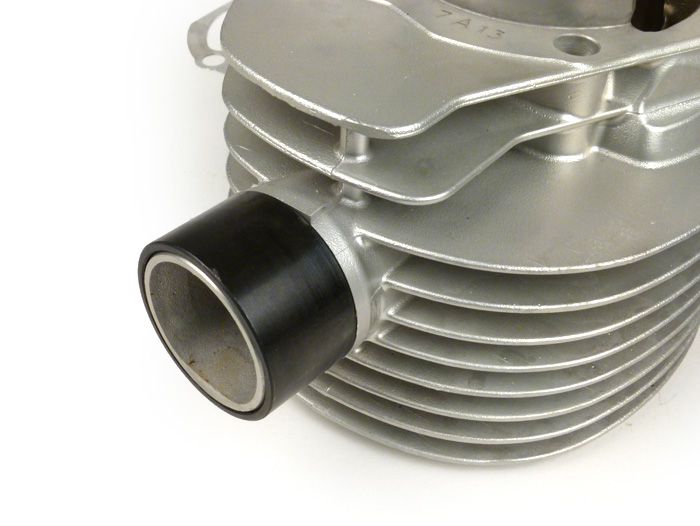

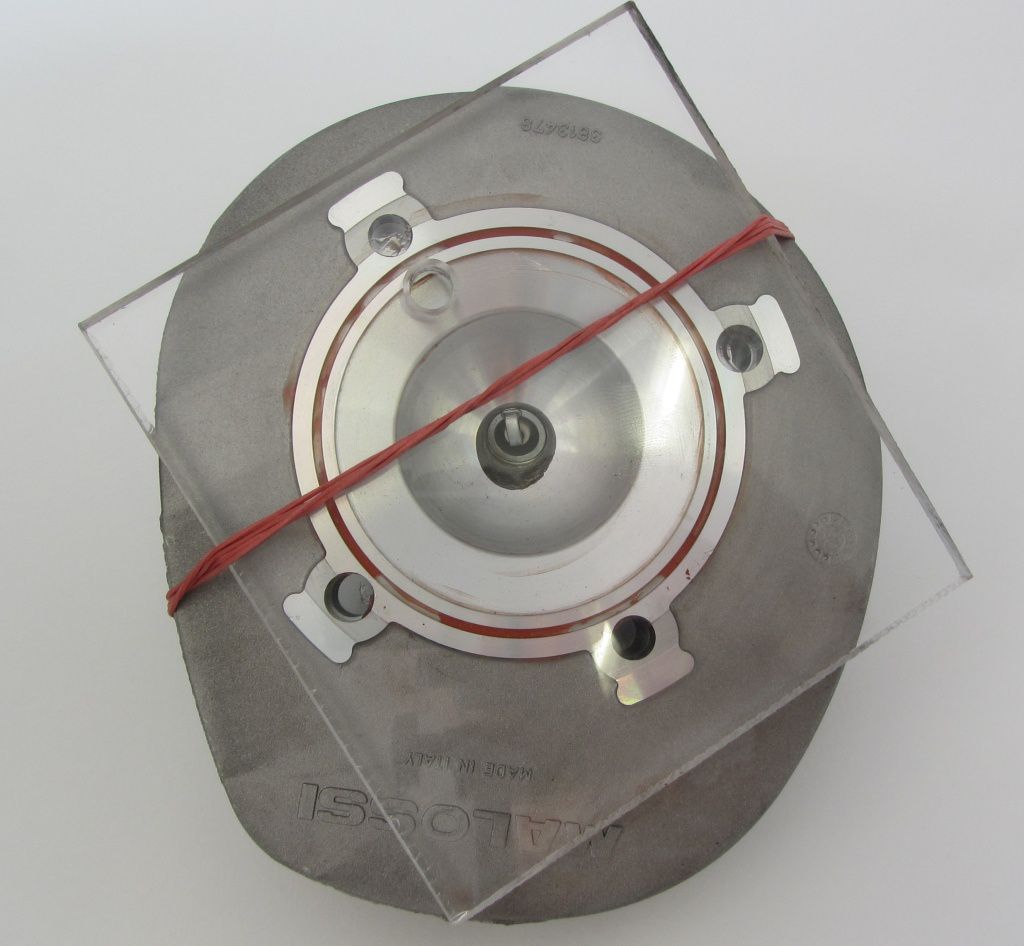

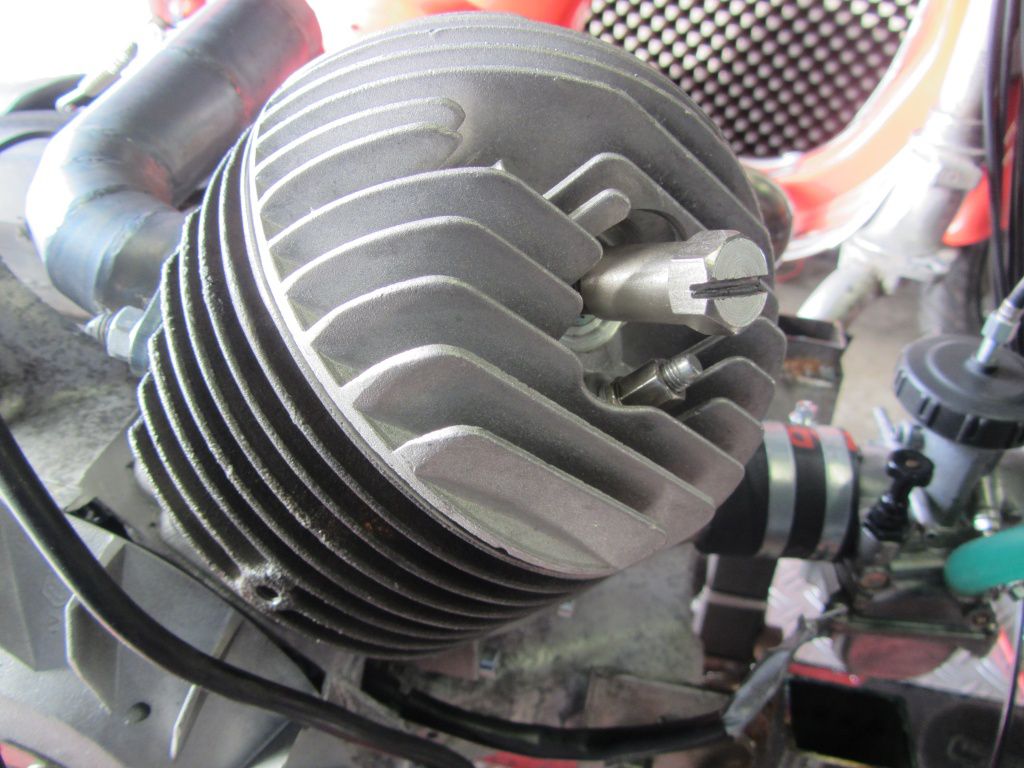

From 2014, a standardized package is permitted in class 1 of the ESC. The direct suction serves as the basis for this package Polini Evolution cylinder modified to the ESC version.

The one-size-fits-all solution with the Polini 133cc Evolution membrane In class 1 the ESC may only be operated unchanged and with the intended exhaust. After consulting Polini and Ludwig & Scherer, we were able to achieve a package price of currently € 625 for ESC drivers. Approval for the purchase of the kit must be obtained through the ESC respectively. You can find the current set of rules at www.eurochallenge.de

The basic idea of the standard solution is that as a driver, as in class 5, in class 1 you can concentrate more on actually driving on the track than on the sometimes quite complex engine concepts.

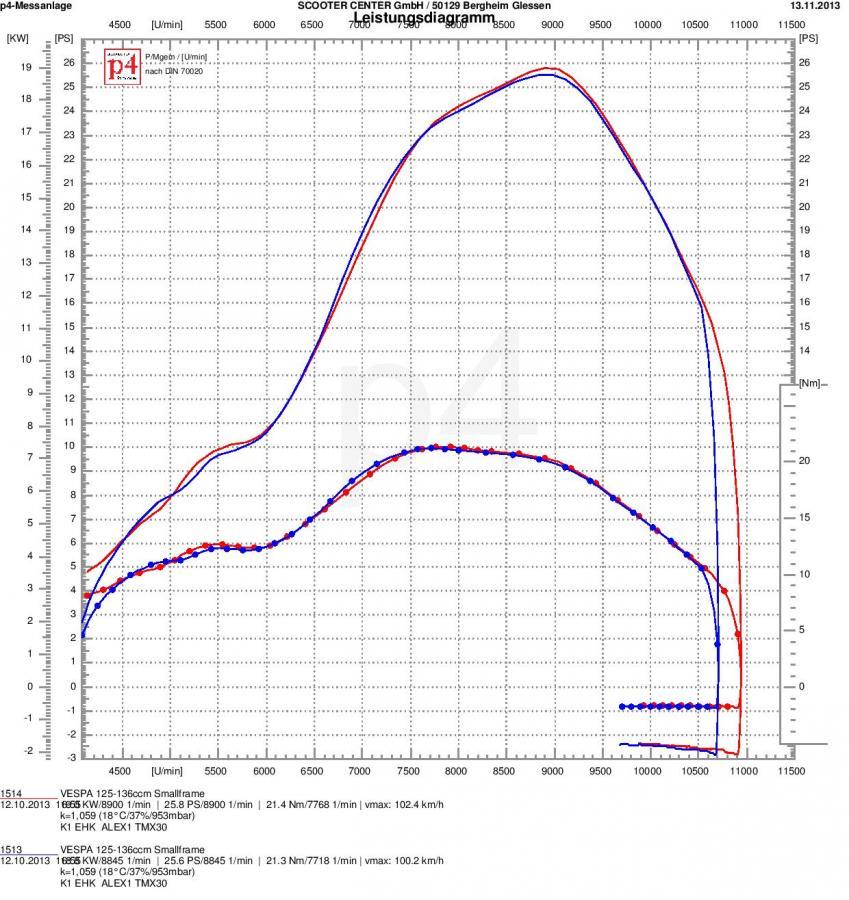

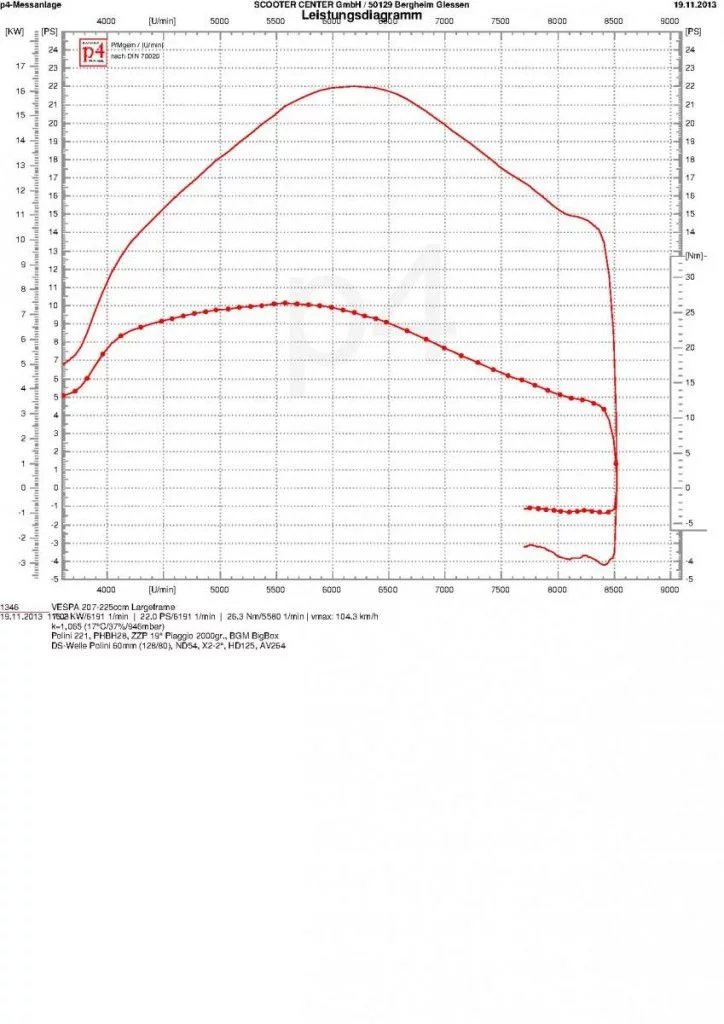

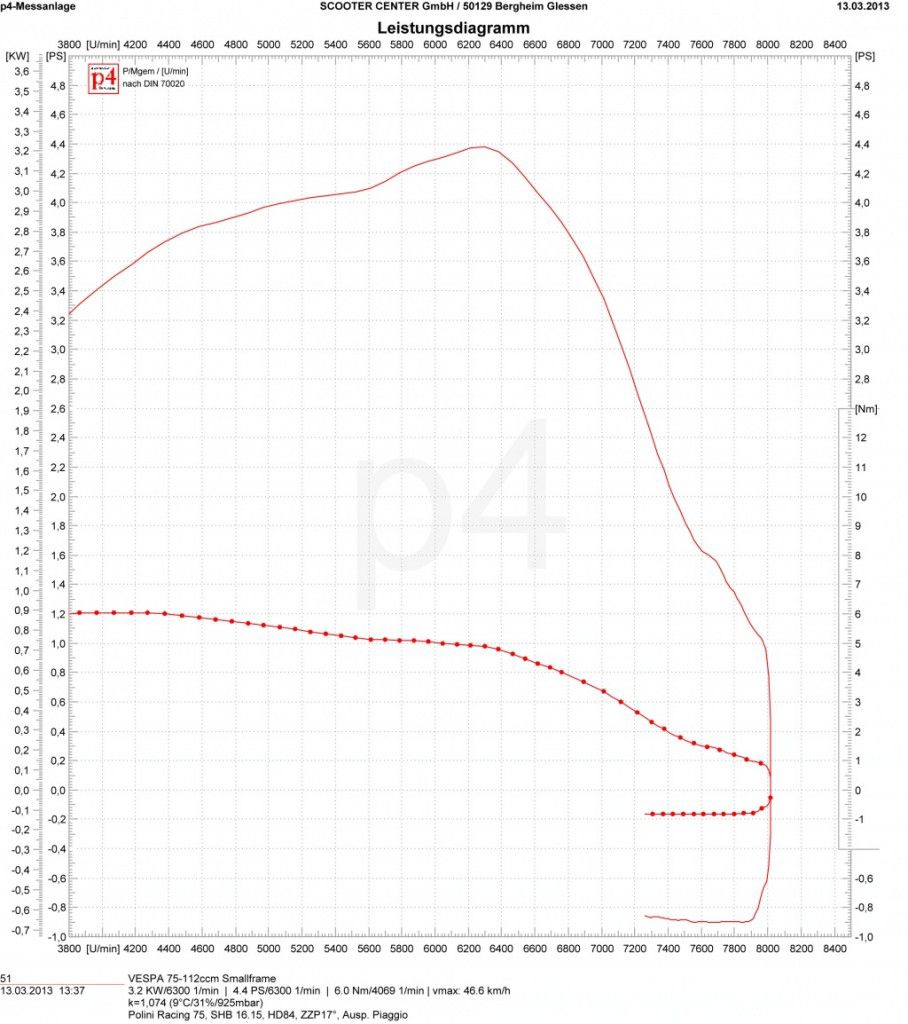

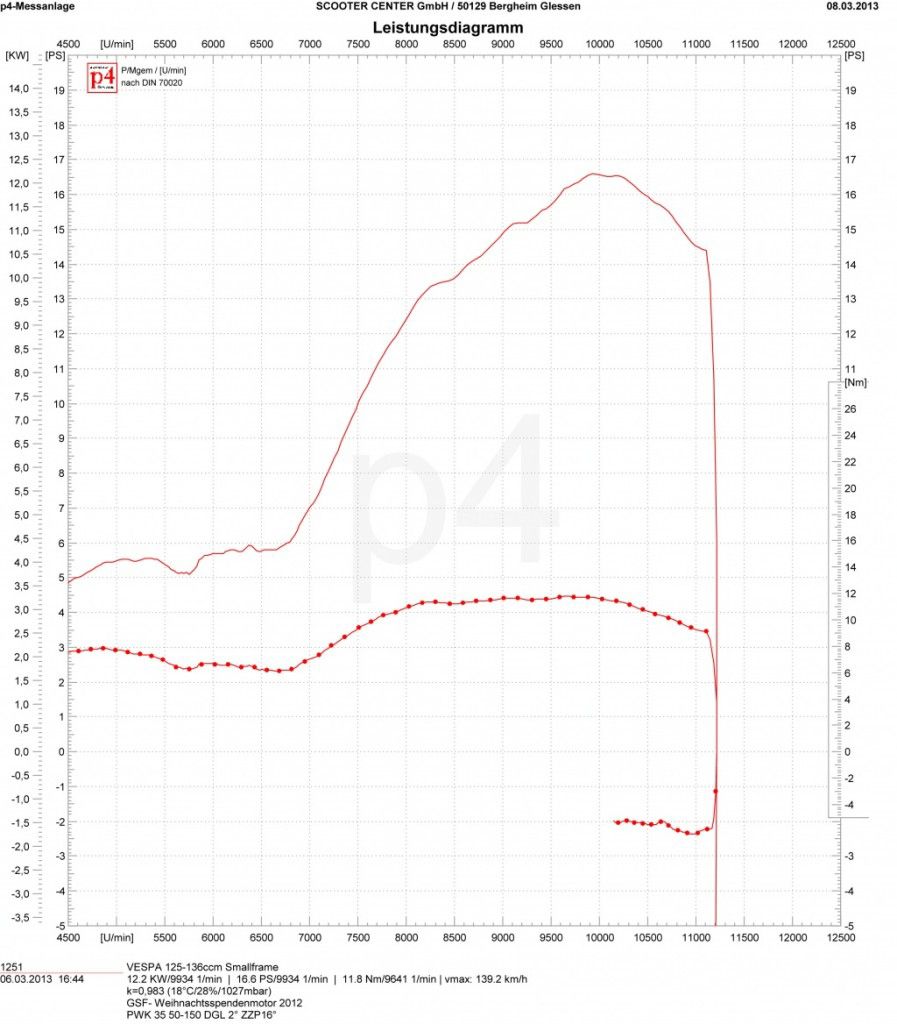

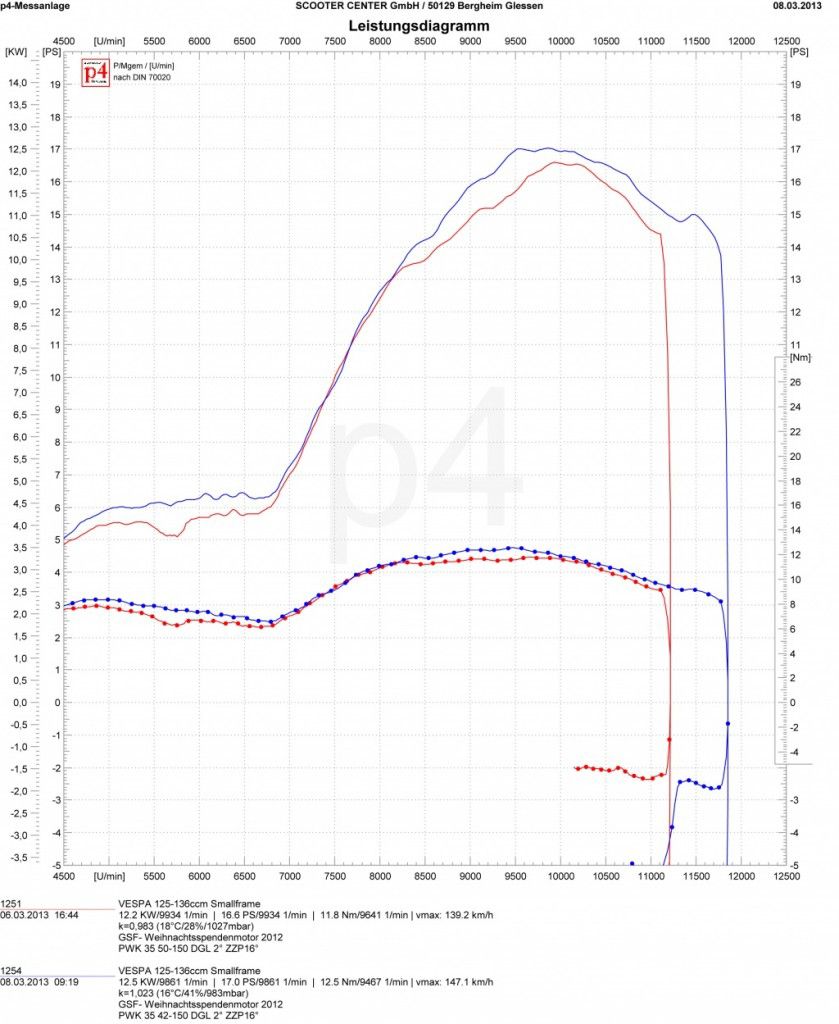

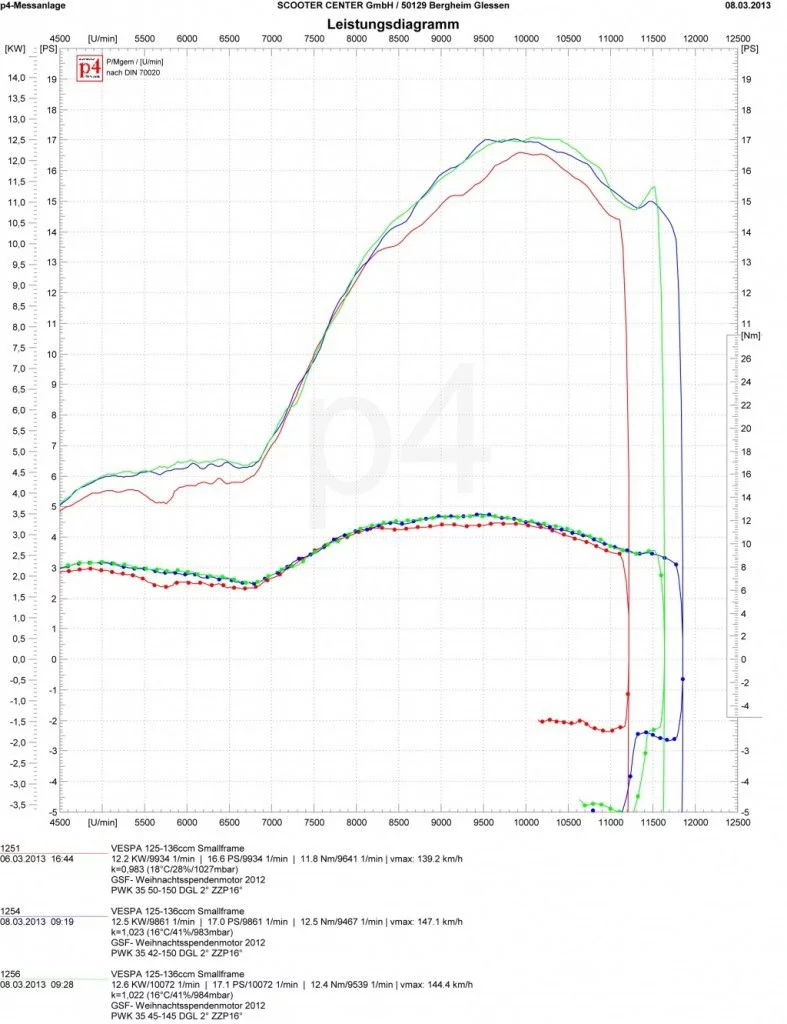

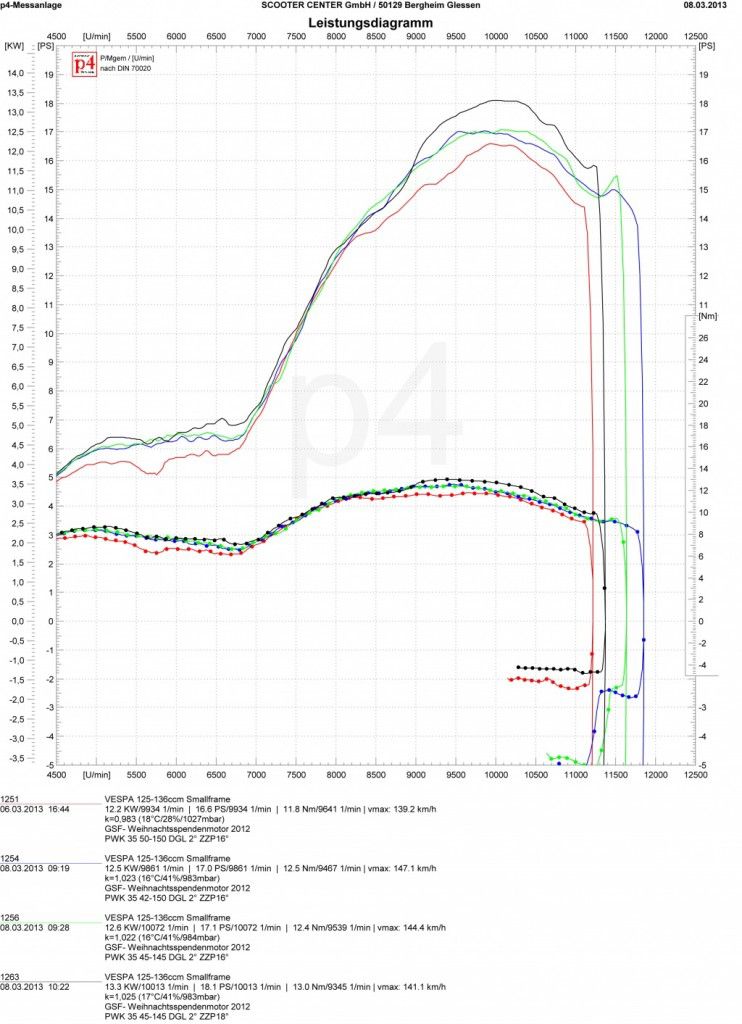

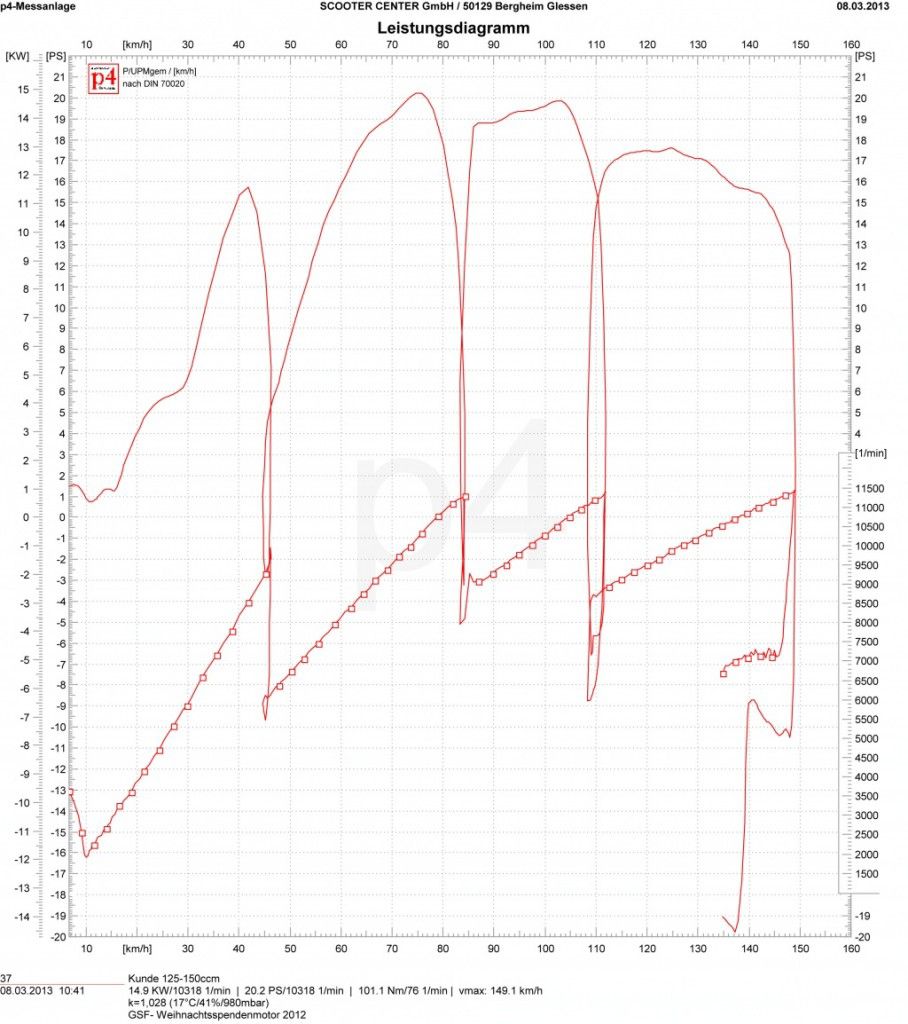

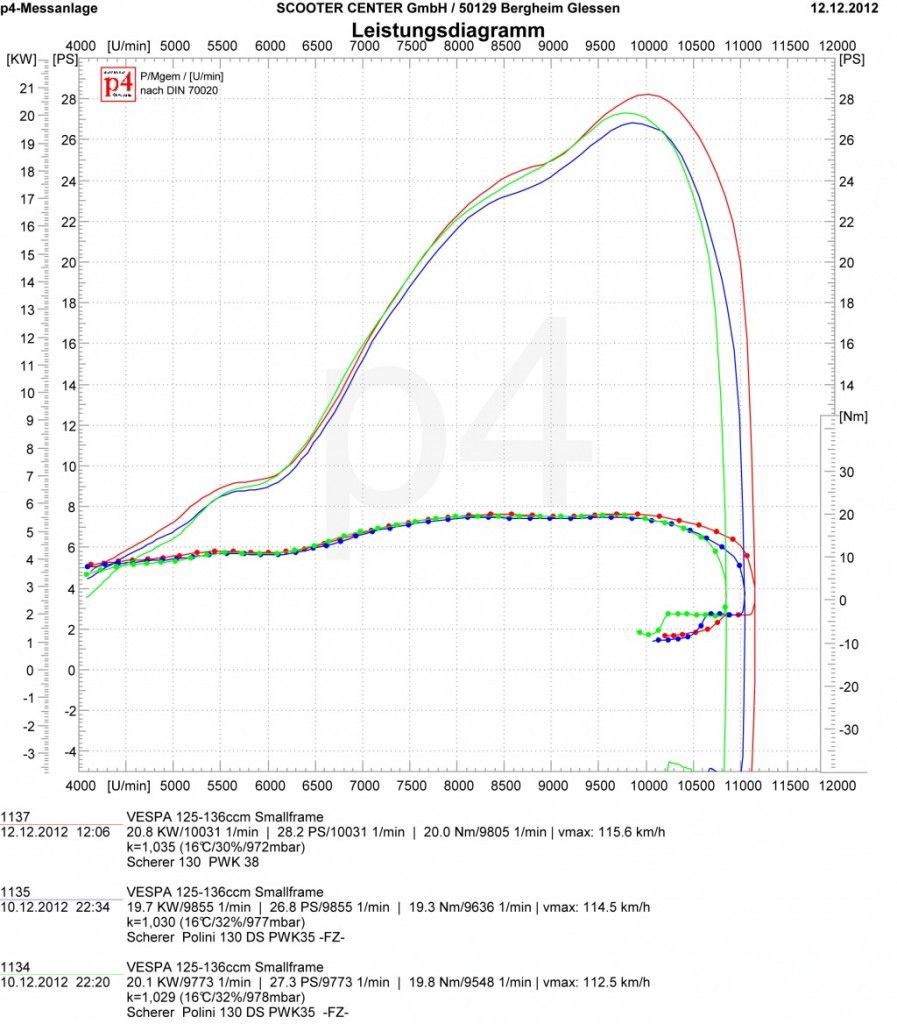

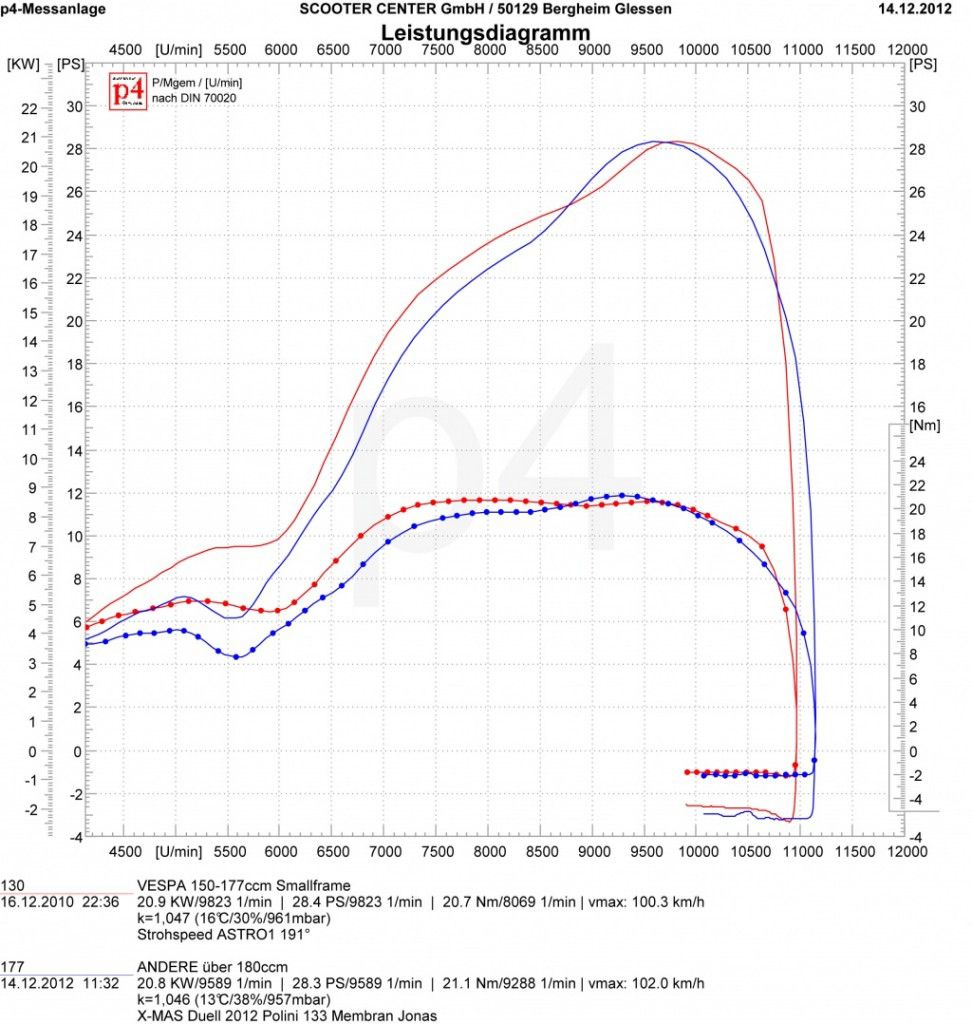

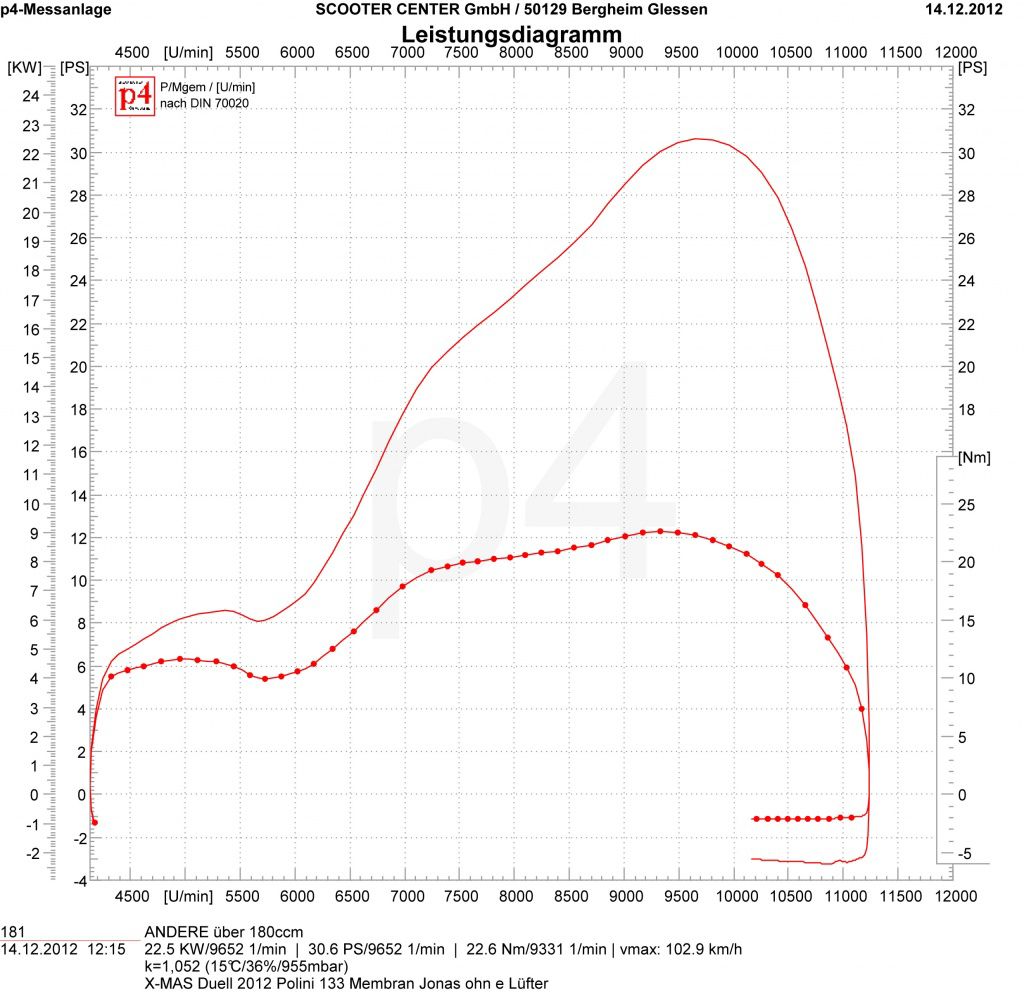

With the “big one-size-fits-all” and the Polini 133ccm Evo, an output of approx. 25PS is possible. In close cooperation with the ESC, we have created this kit for you and run some tests on our P4 test bench.

That up 51mm stroke reworked cylinder kit You can of course also move normally on the street after the TüV blessing. Even if you do not take part in racing events in the ESC, we can prepare this kit for you. But then at the regular price, as the cylinders for ESC use are specially discounted by Polini.

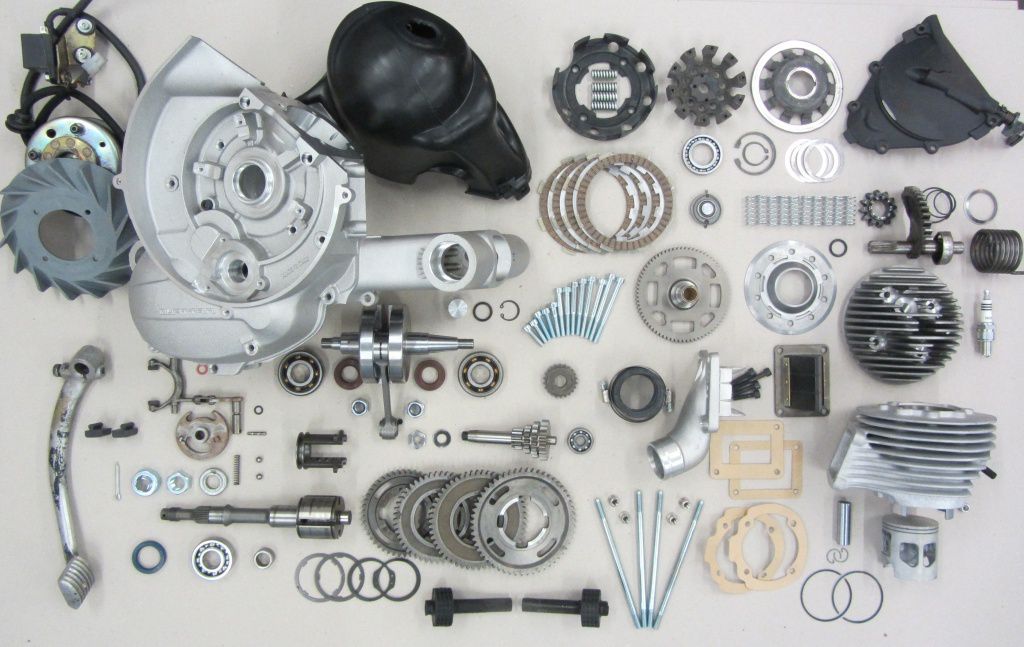

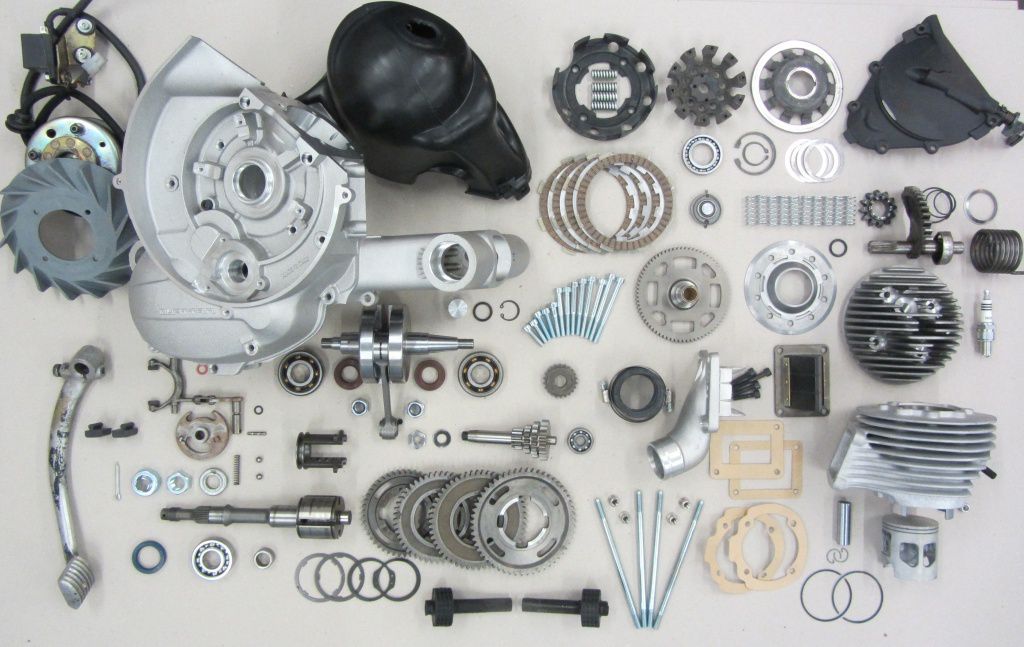

So that you can install the cylinder, you should pay attention to a few things in detail.

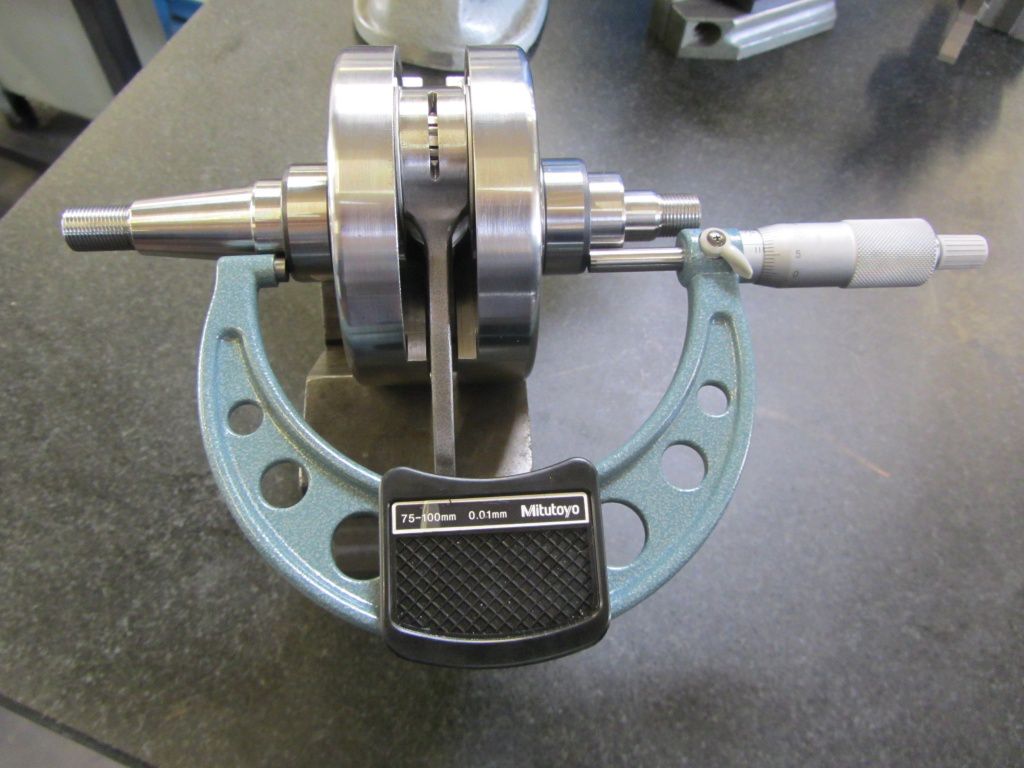

Crankshaft / crankcase

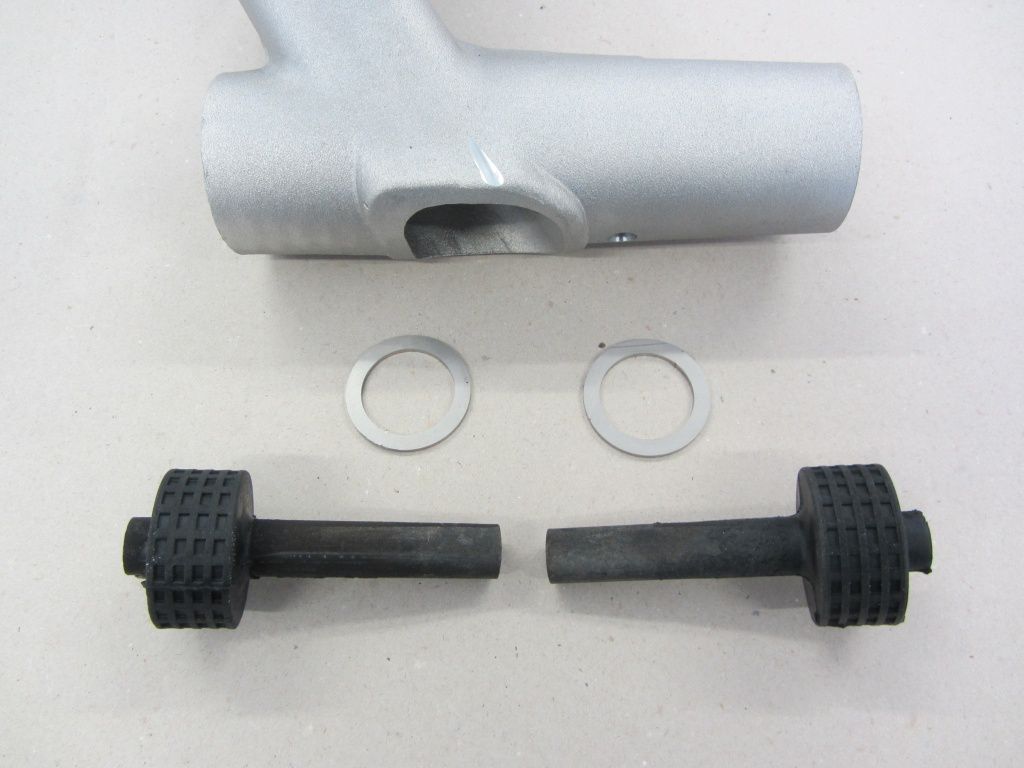

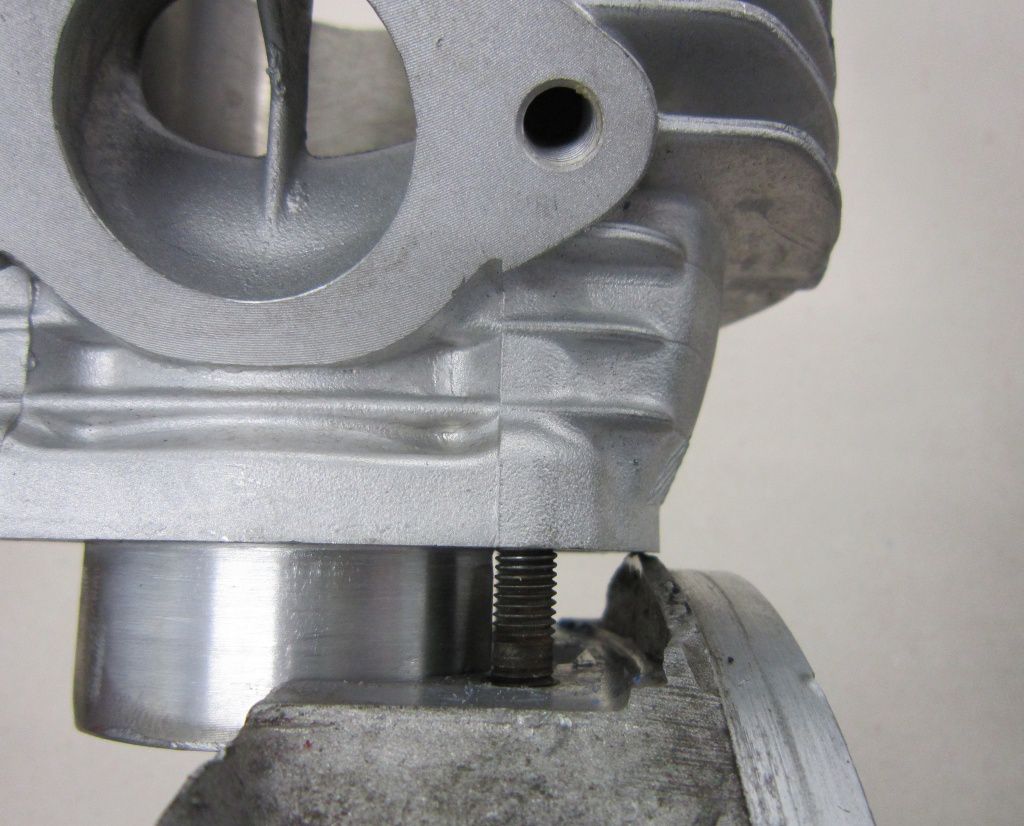

The cylinder kit has been revised for the use of a crankshaft with 51mm and 105mm connecting rods and supplemented with a matching spacer.

The following crankshafts fit this:

bgm Pro 51/105 ETS 24mm and bgm Pro 51/105, 20mm and of course all other crankshafts, which have a stroke of 51mm and a connecting rod length of 105mm.

A crankshaft with a standard connecting rod length of 97mm cannot be used.

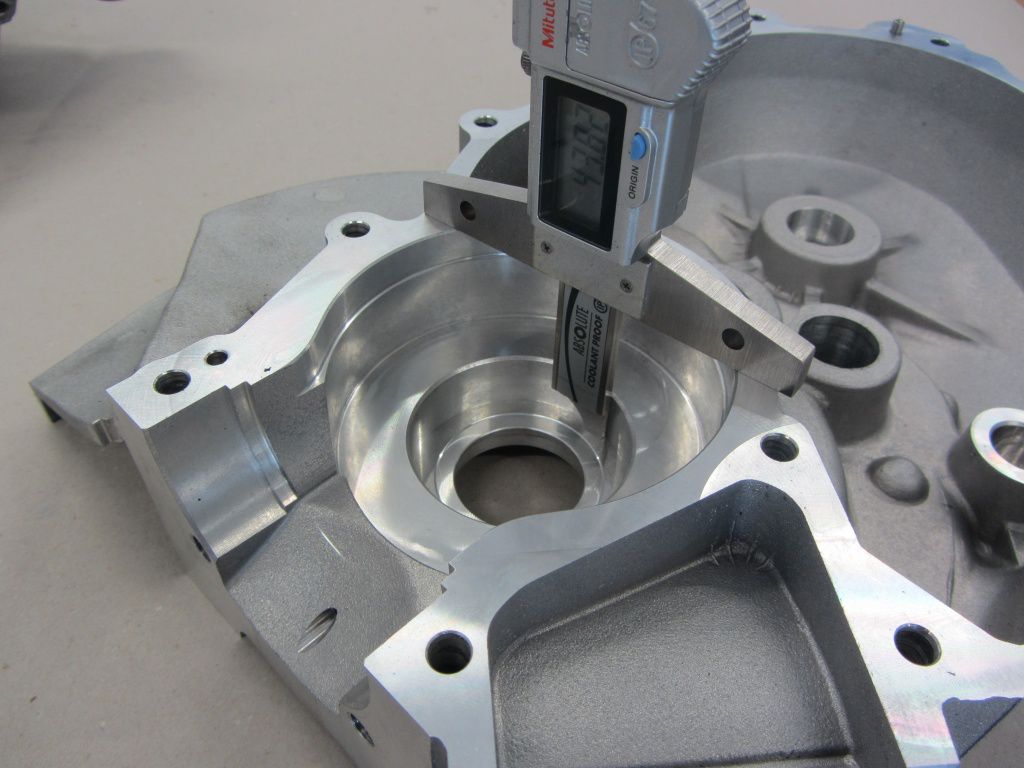

To install the bgm crankshaft you have to prepare your crankcase.

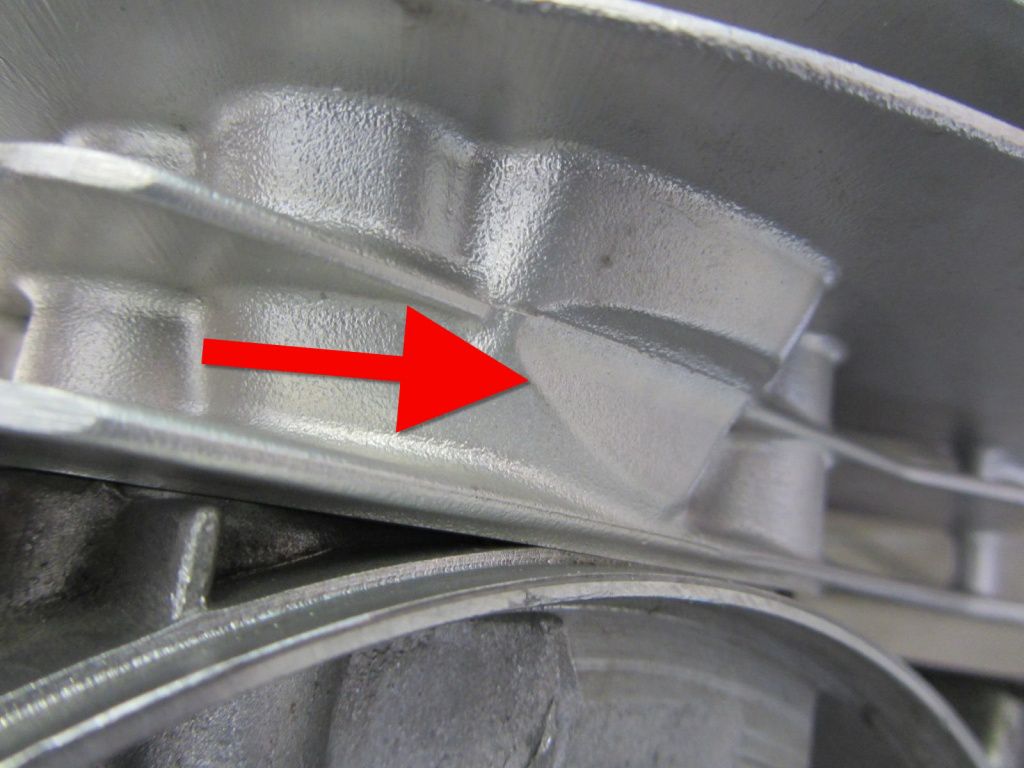

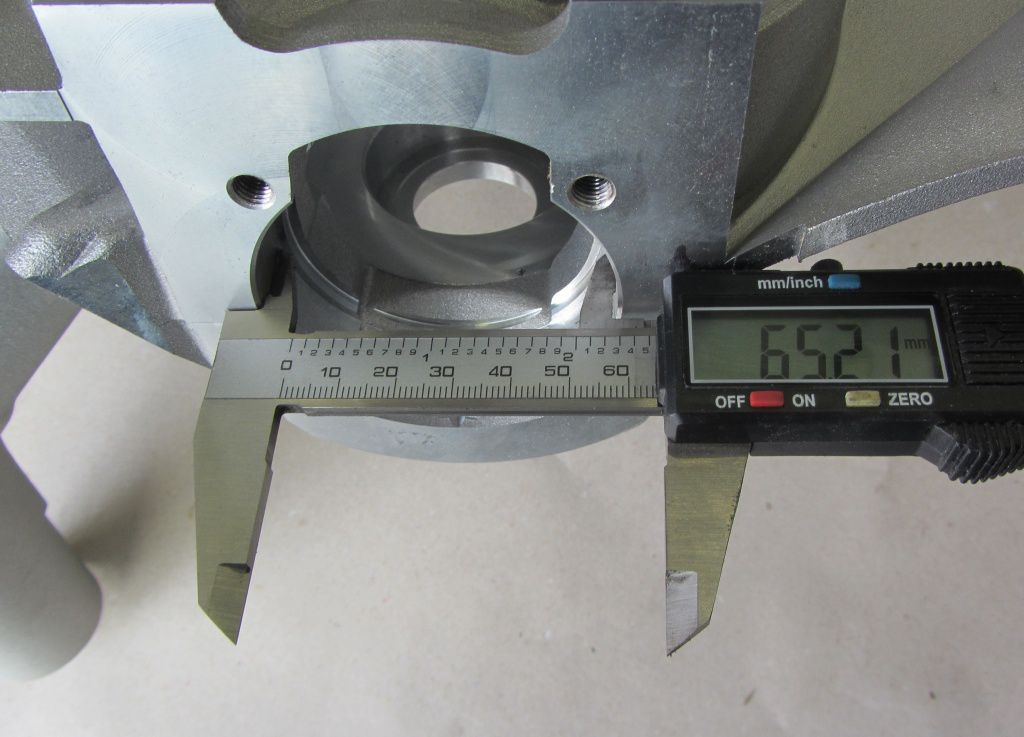

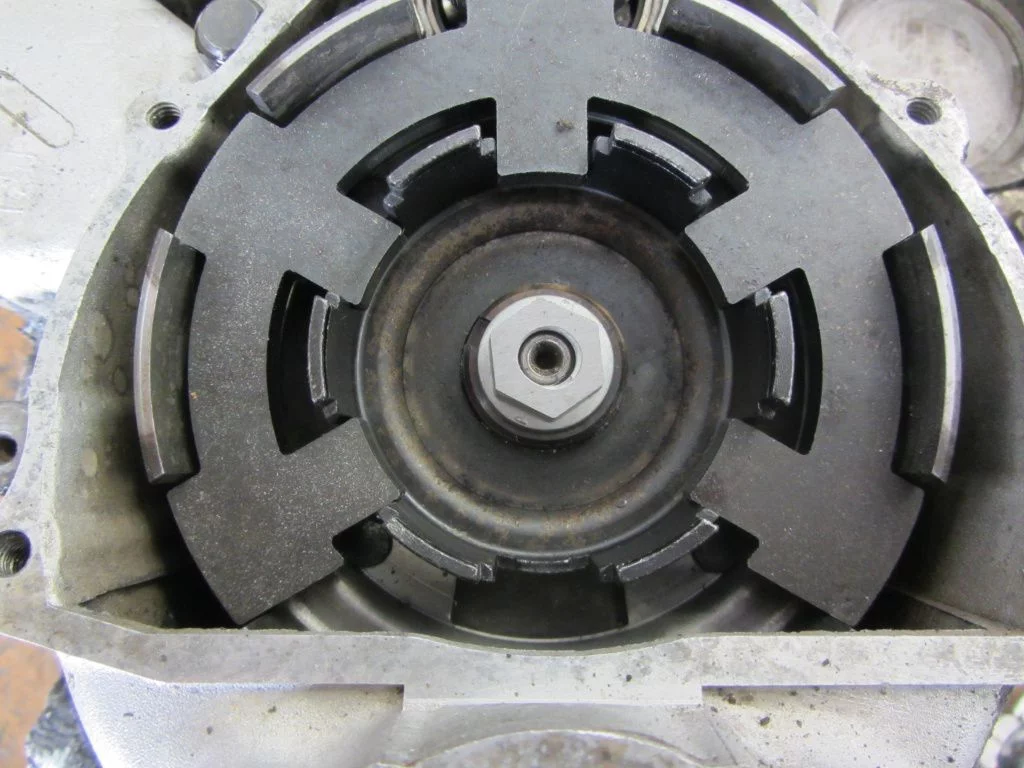

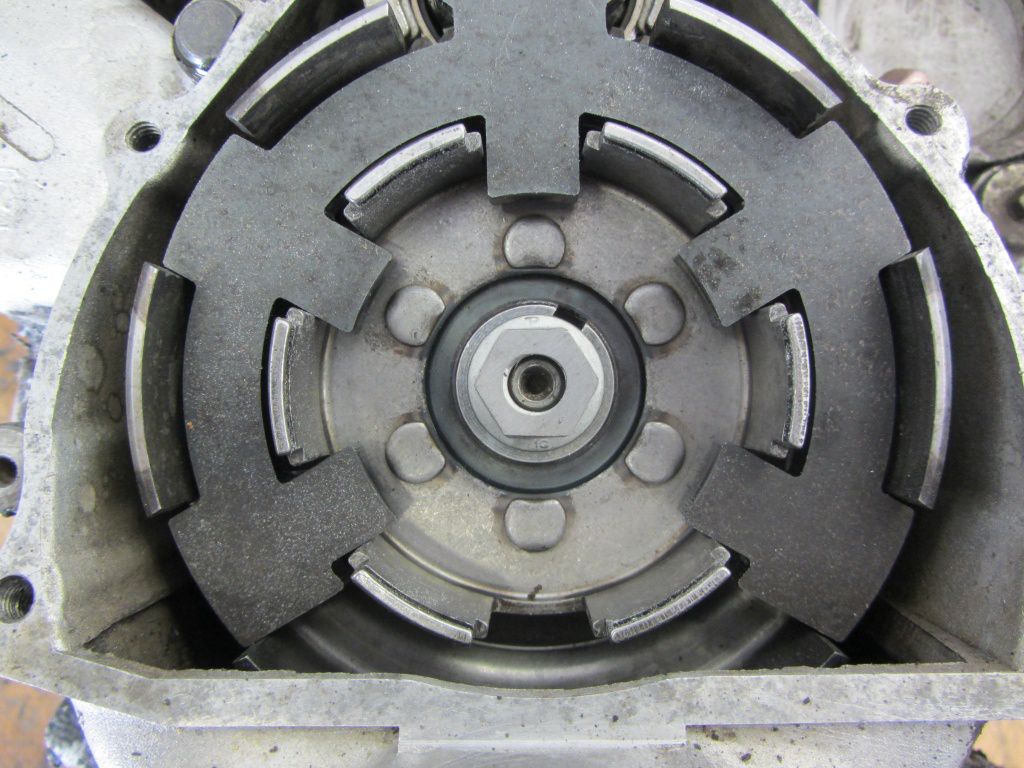

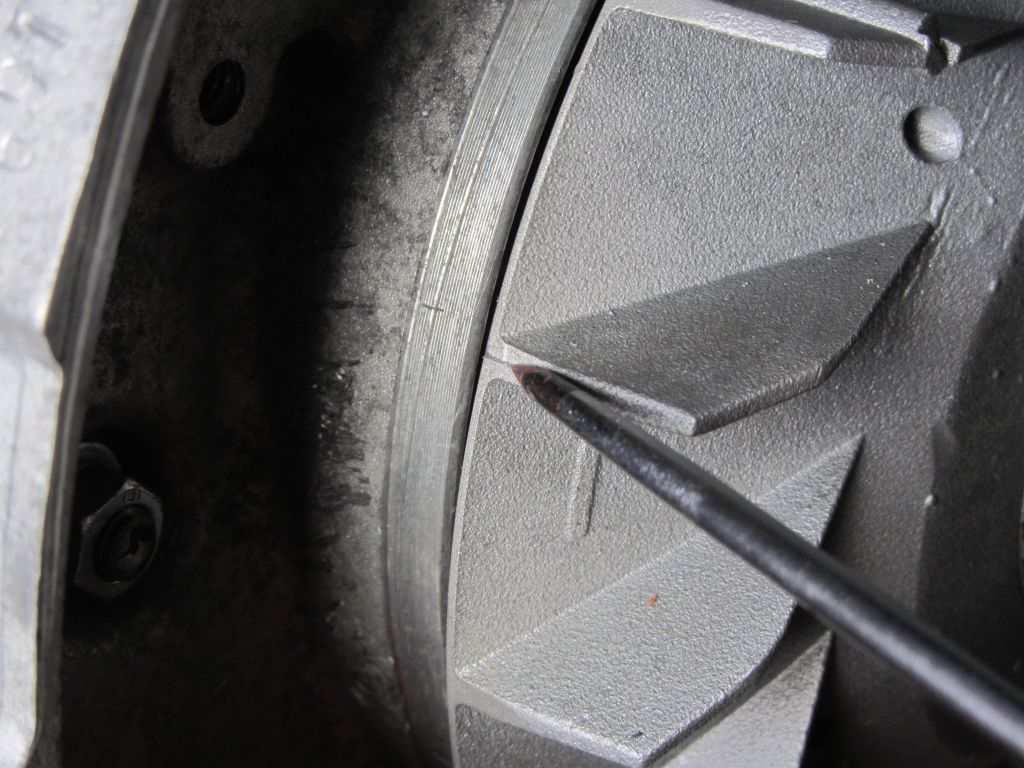

In the “small engine half”, ie on the generator side, the diameter of the crankcase must be enlarged to 88mm.

In the large half of the housing, the drive side, it is usually sufficient to remove the rotary valve sealing surface.

You must also pay attention to the clearance of the crank webs and the connecting rod above the rotary valve sealing surface.

When building the engine, we recommend that you store the crankshaft Ball bearings with increased internal clearance and FPM shaft seals to use. These can still work trouble-free and permanently even at higher speeds.

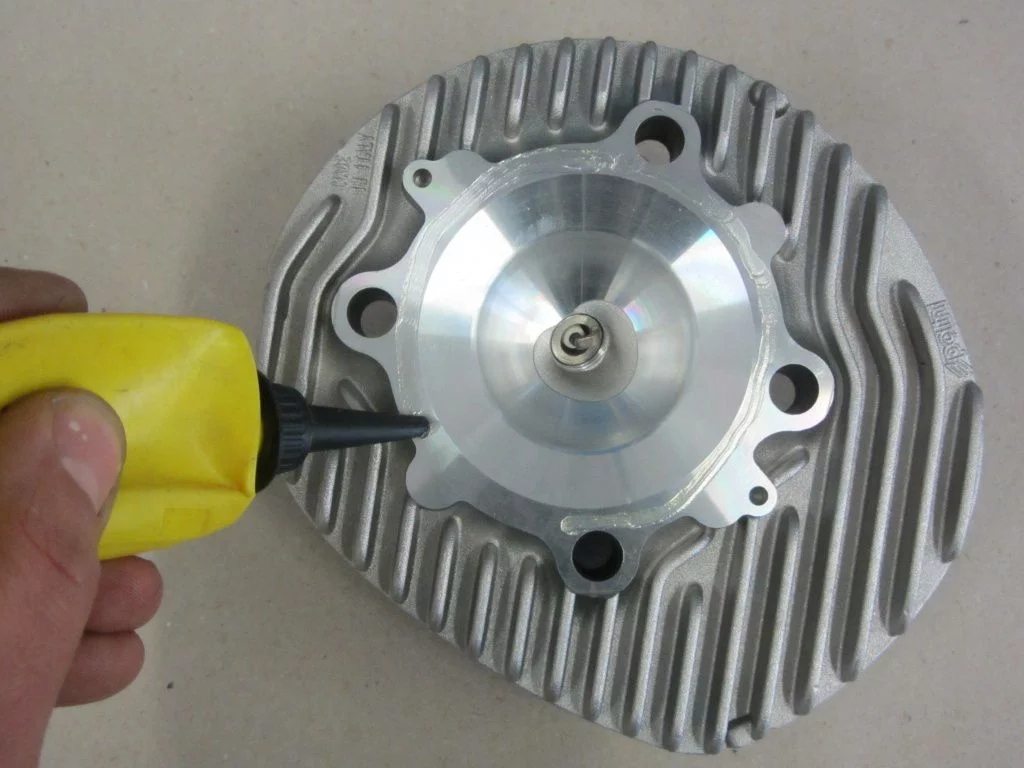

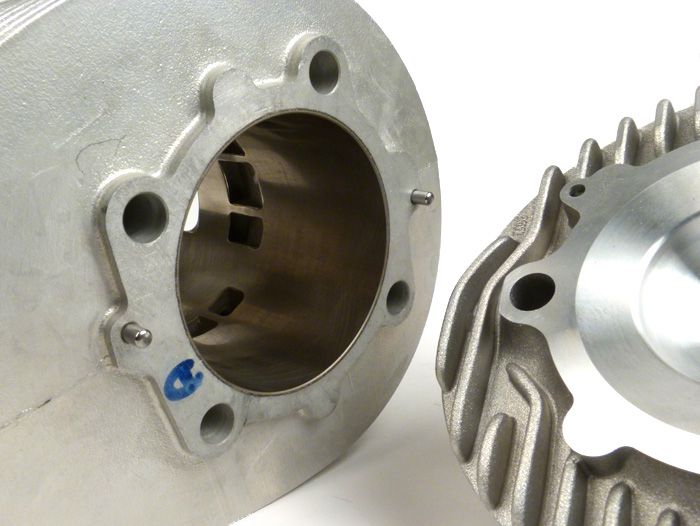

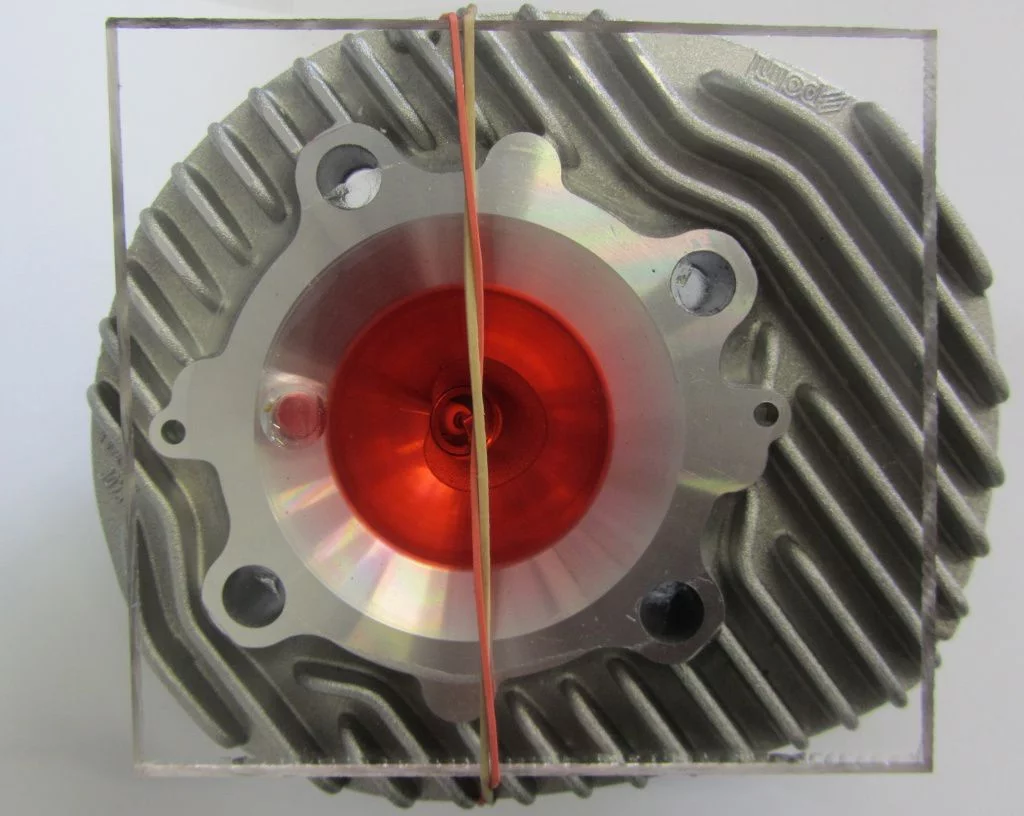

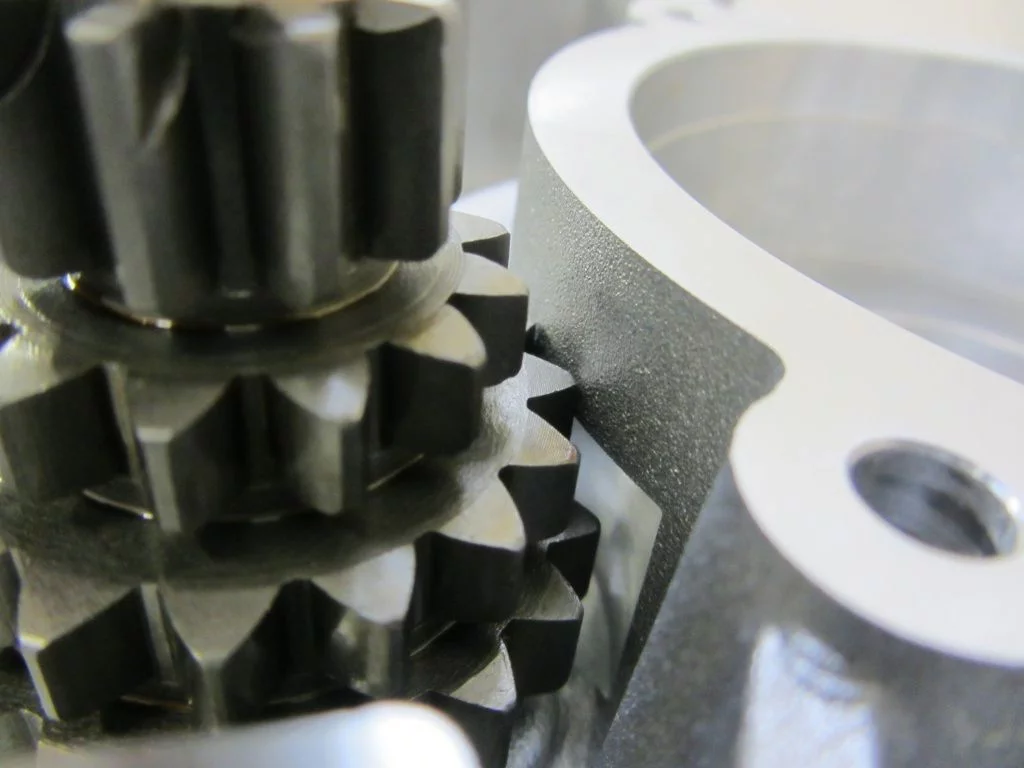

Cylinders / overflow channels / cylinder base

Every now and then it can happen that the coating on the cylinder base creates a few burrs. It is therefore advisable to deburr the edges before assembly.

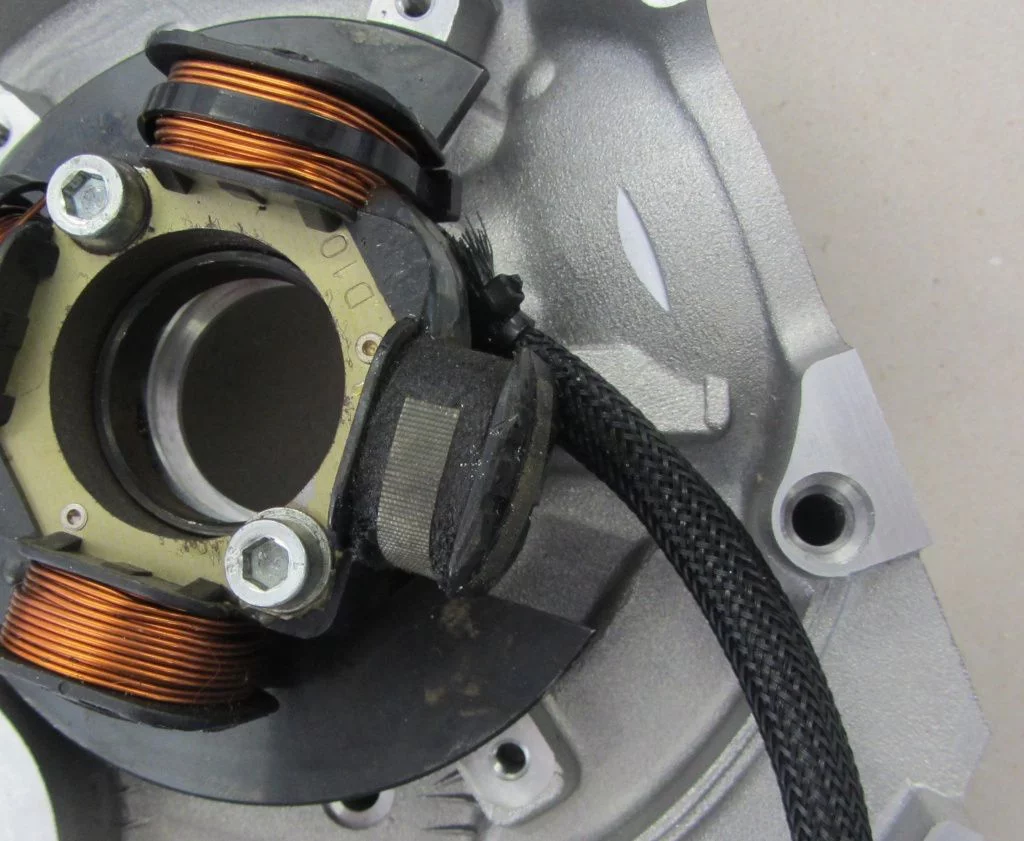

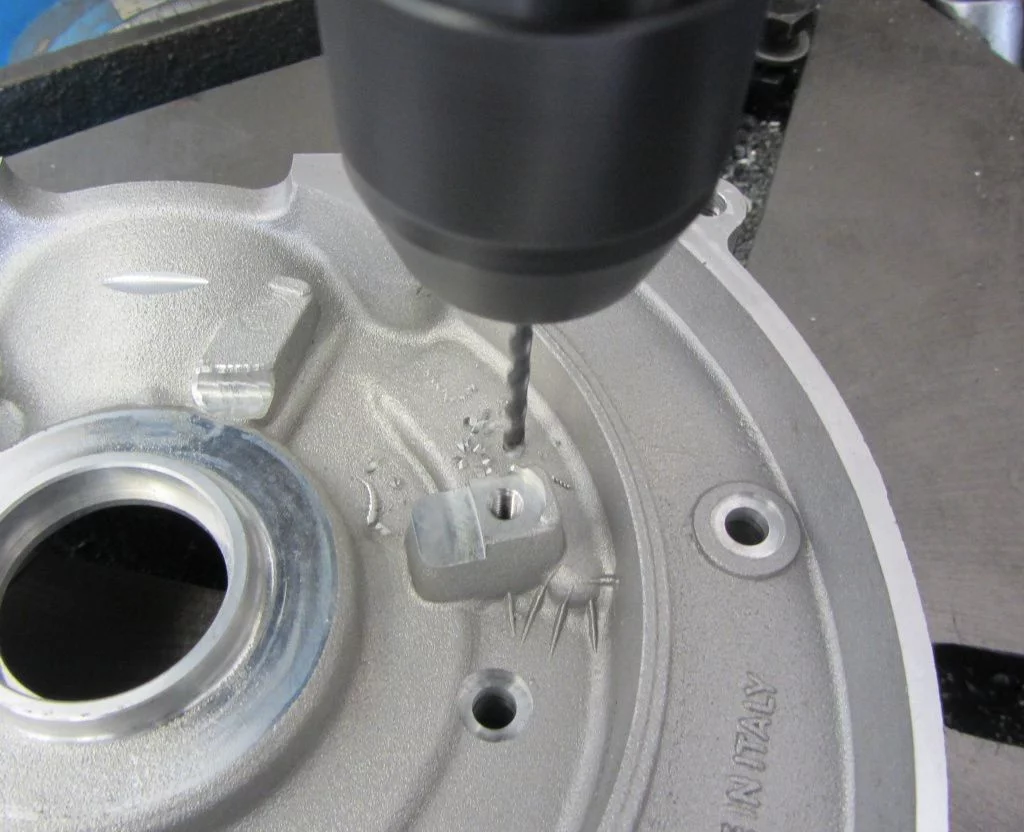

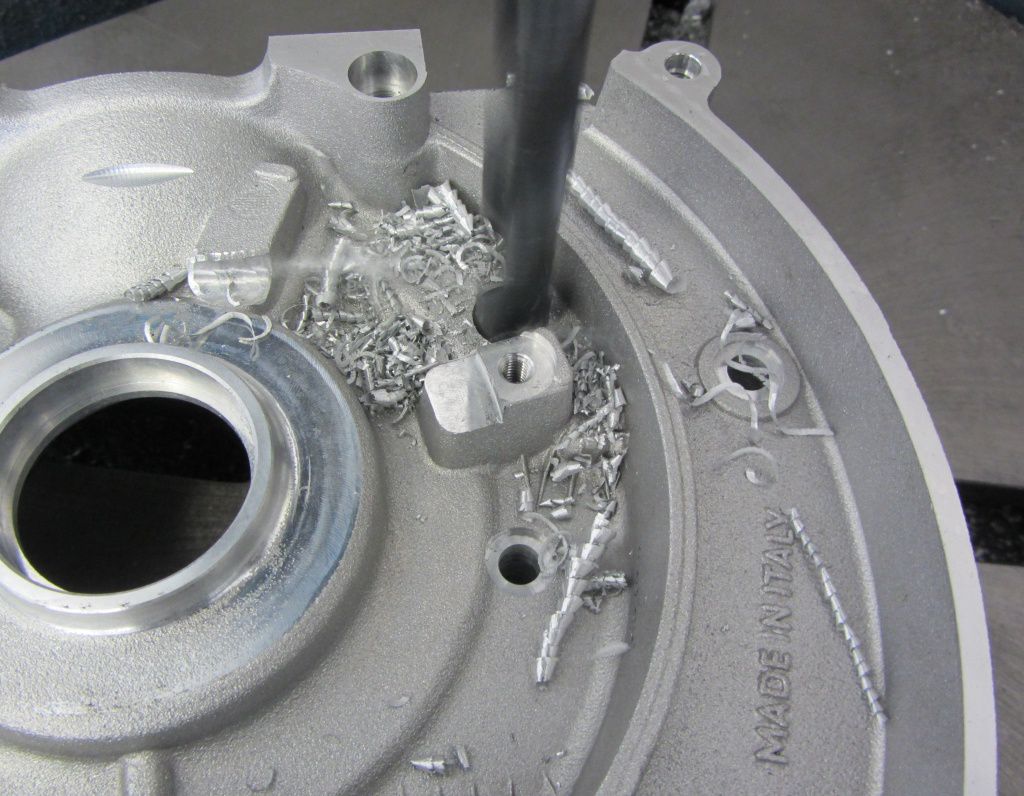

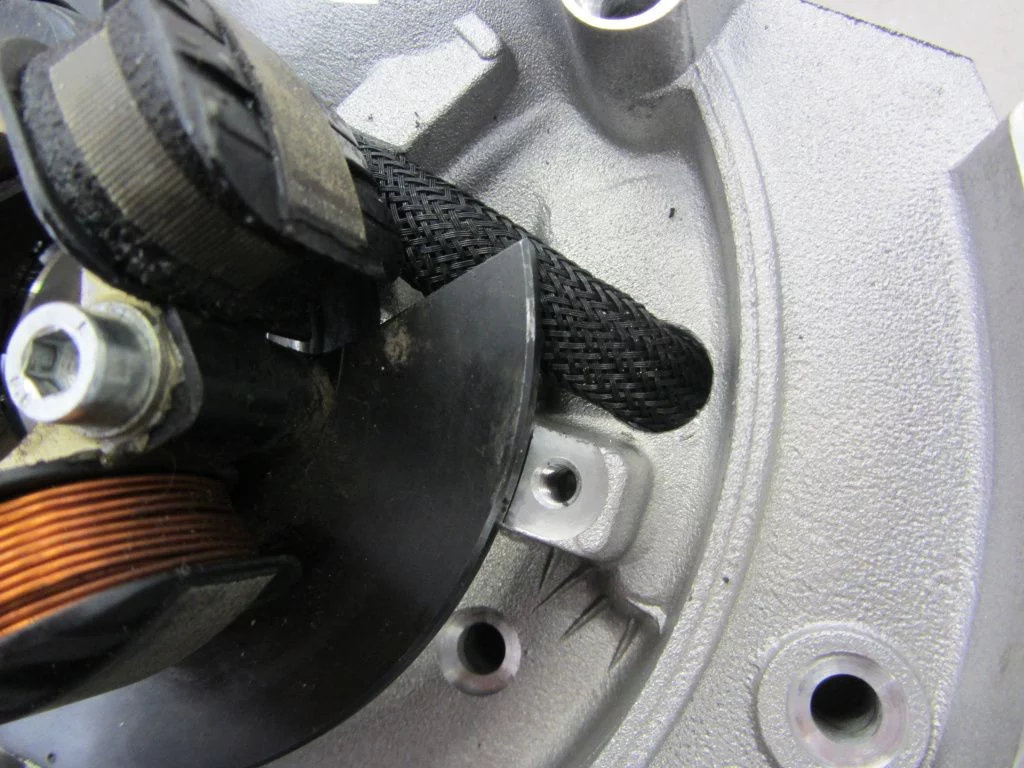

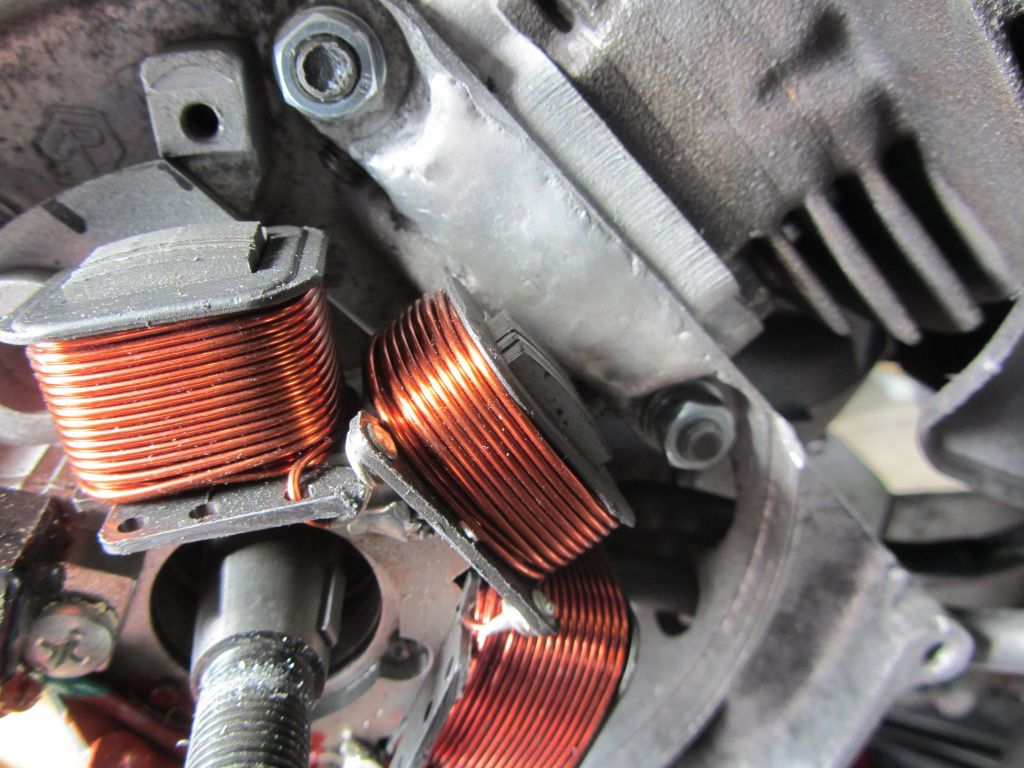

In order to accommodate the large overflow channels, the Polini cylinder is significantly larger in the area of the channels than, for example, a gray cast iron cylinder. Therefore you have to edit your stator housing.

It is not absolutely necessary to plan the motor housing by machine. The part of the stator housing can also be easily removed with a saw.

Since there is no need to seal the surface, you can simply align the surfaces with a file.

You do not necessarily have to adjust the overcurrent channels in the motor housing. According to the rules of the ESC, however, this is permissible. We could not determine a performance or speed advantage through adapted overcurrent channels in the housing on the test bench. The overflow system clearly lives from the direct ventilation from the direction of the membrane.

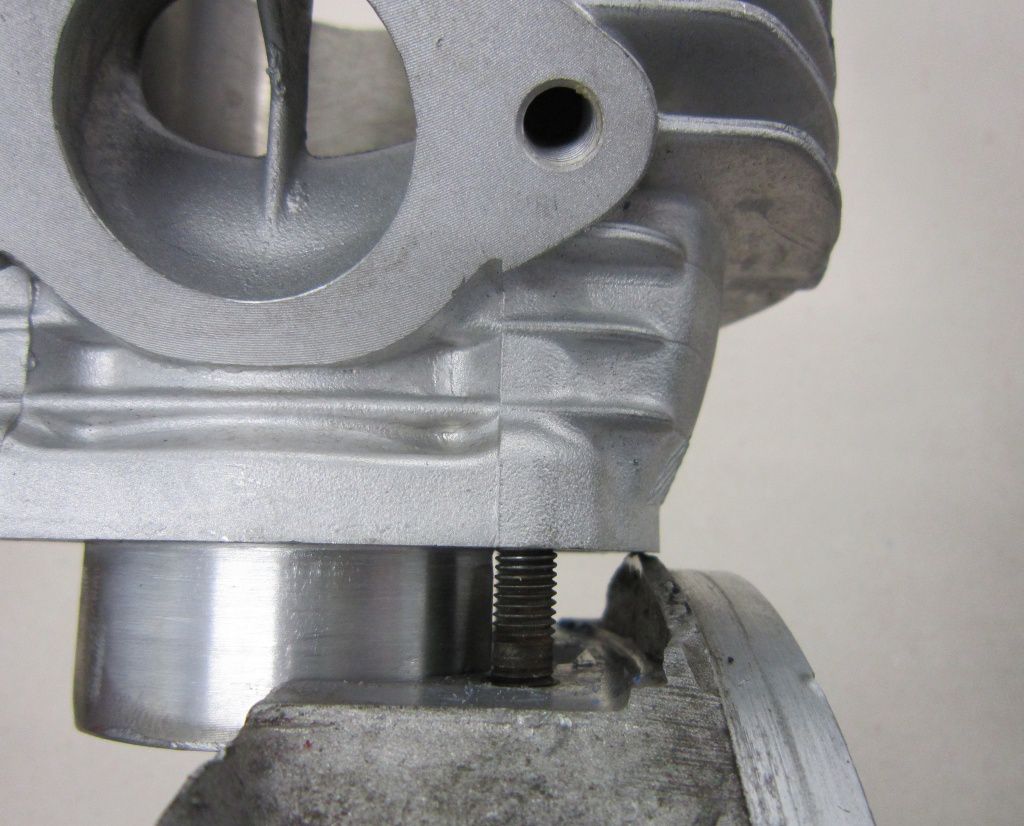

Intake manifold / membrane / spacer

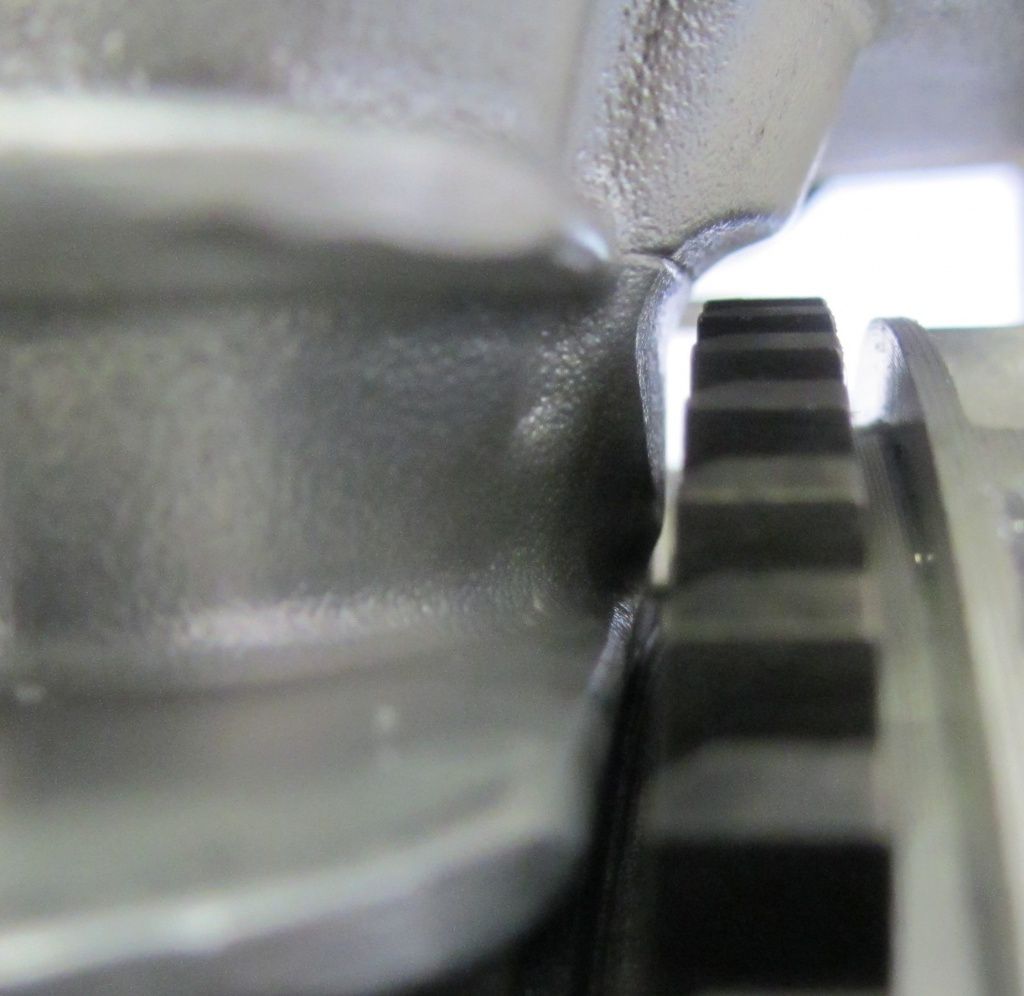

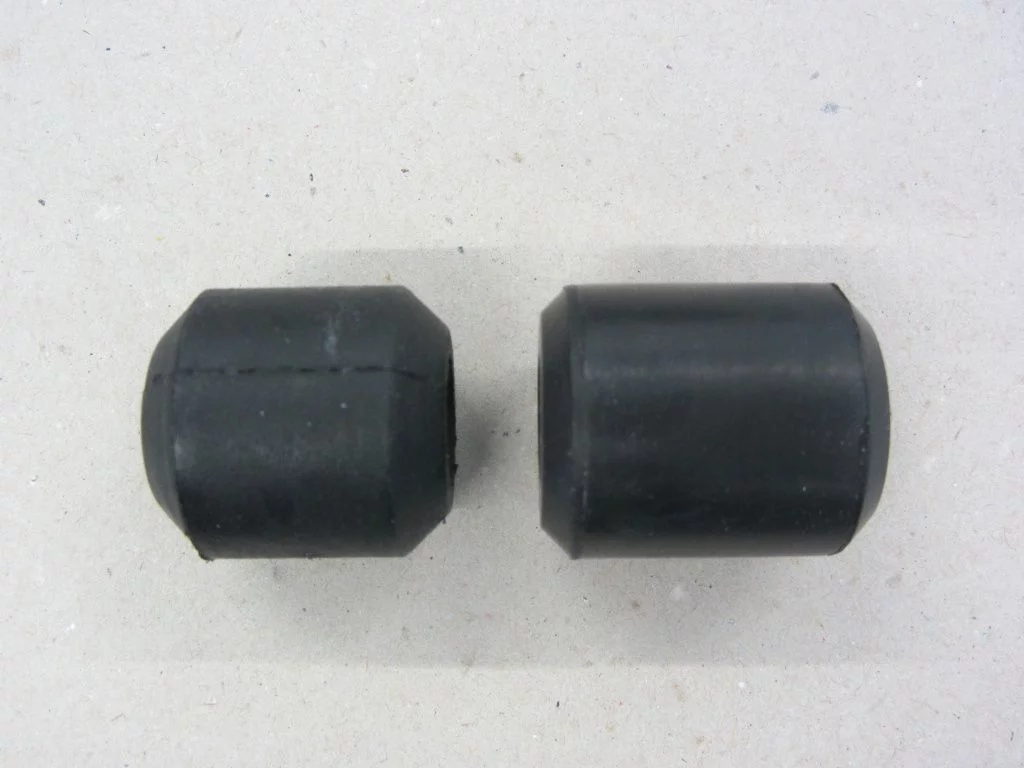

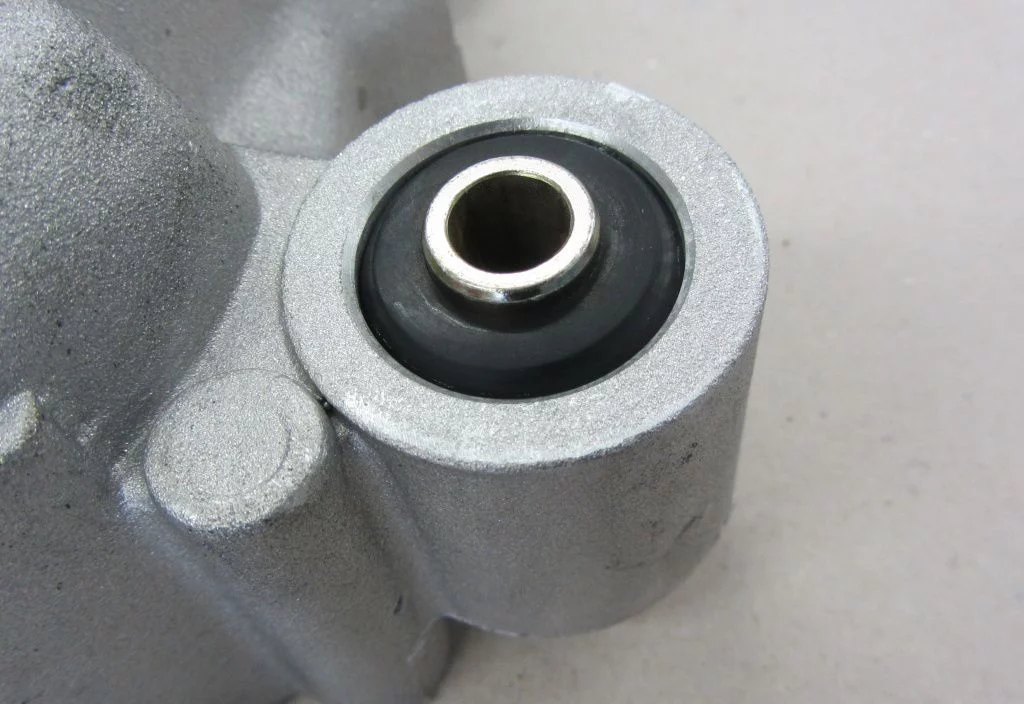

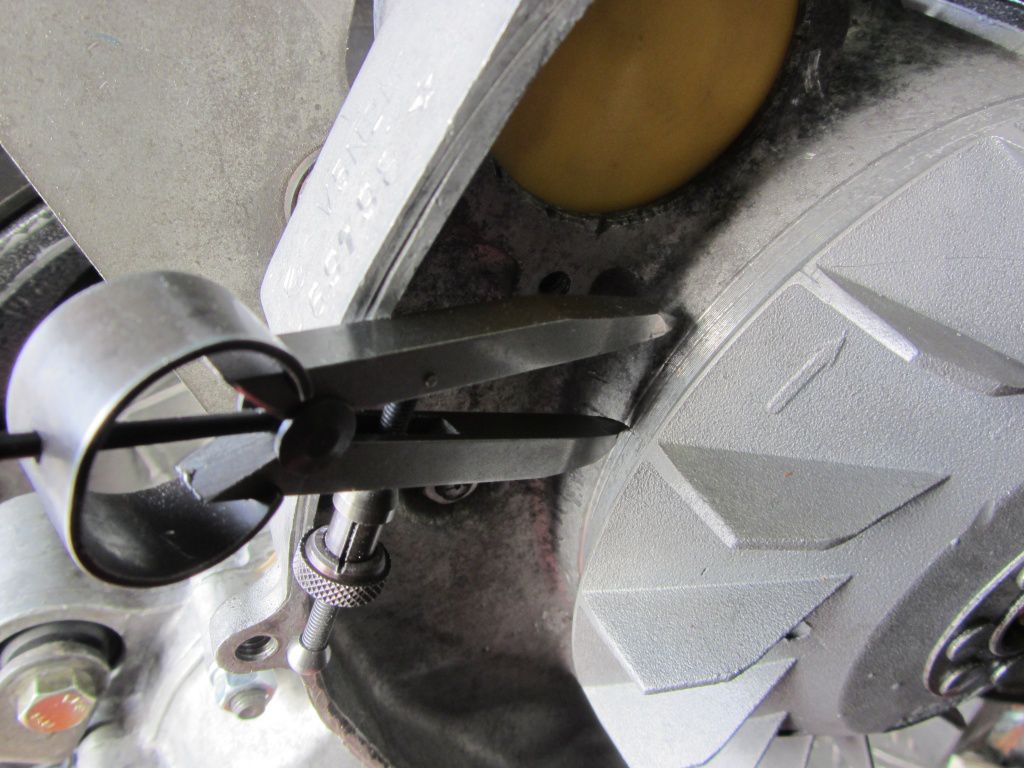

Due to the fact that the cylinder is ventilated directly, the housing inlet must be closed.

This can be done on the one hand by filling the intake tract with so-called. Cold metal happen or through a Locking plate , the latter is available for 2-hole and 3-hole motors

When using cold metal, the inlet channel can only be reused with increased effort. With the locking plate, you have the option to use a housing-sucked cylinder at any time.

We used a locking plate on our engine.

After the assembly you have to adapt the locking plate to the cylinder.

Optionally, you can also edit the spacer to create the necessary space for the closure plate.

The intake manifold of the Polini cylinder is designed for good flow and thus for good performance. However, the shape of the suction means that space must be created accordingly on the frame. Depending on the model used, V50 or PK, more or less large modifications are necessary here.

If you do not want to change your (racing) frame appropriately, you may optionally also use one according to the rules Intake manifold from MRP use. Due to the other course, the intake manifold fits into your scooter without major changes.

The good fit is unfortunately due to the performance compared to the Polini intake manifold.

You may not process the Polini Memrban any further, for example by separating out the bars, etc.

As a replacement or optional you can Carbon plate material or use one-piece membrane plates in any material thickness. You are not allowed to use Boyesen membrane plates, a similar, multi-part principle or any other membrane in class 1.

CARBURETOR

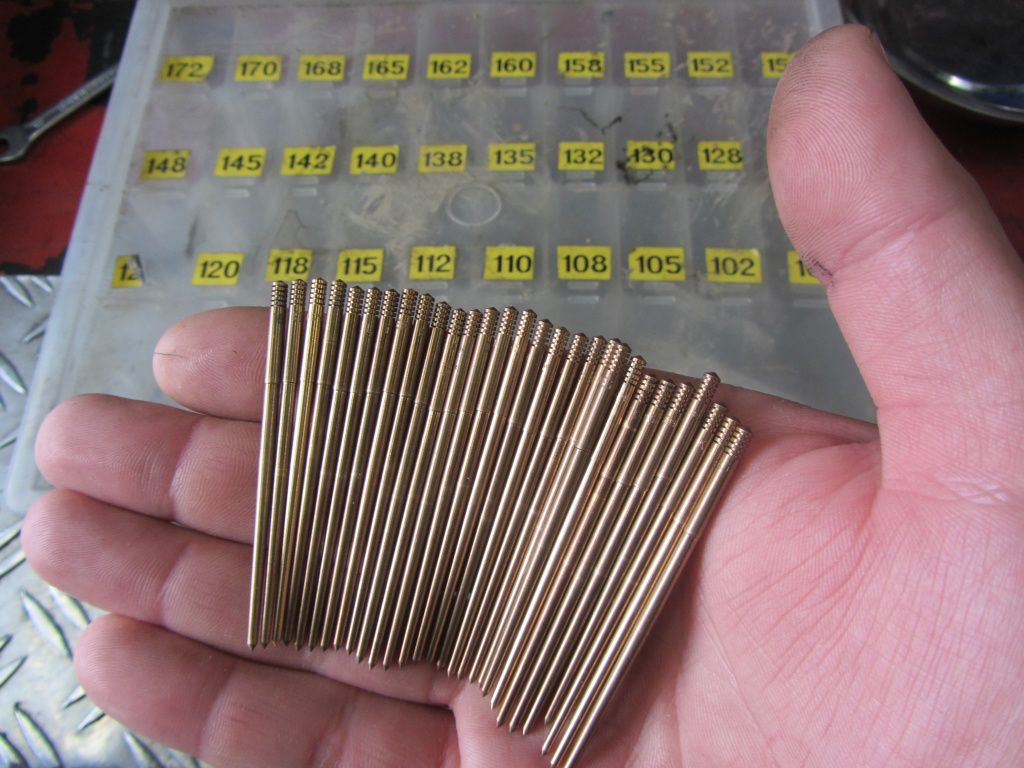

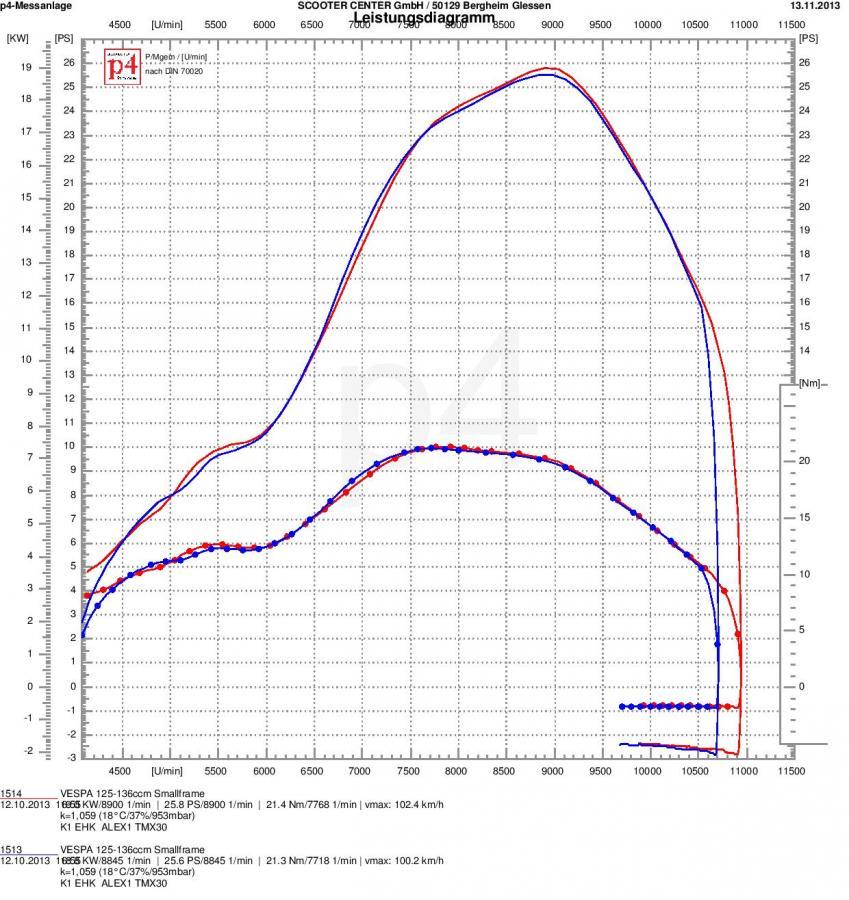

We used a Mikuni TMX 30 and a Keihin PWK 28 on the test engine we assembled.

Since our test engine has already driven almost all ESC routes, we can also give you some tips on how to set it up correctly. Of course, these tips are only intended as a guide. You have to find out the exact setting yourself on your engine, but so that you don't have to start from scratch, we have briefly summarized the jets we use on the routes.

MIKUNI TMX 30

Idle jet 20-22,5

5EL-68 needle 2 ° -3 °

Main jet 260-280 (with PJ!)

Powerjet 85-100

Keihin PWK 28

Idle jet 38-42

Needle JJH 2 ° -3 °

Main jet 142-148

IGNITION

Here, with our test engine, we have the "Polini tronics ” resorted to. Somewhat more interesting than that in terms of acquisition and equipment Vespatronic. Meanwhile, Malossi offers another interpretation of the IDM based ignition system. A ZZP of 26 ° -18 ° turned out to be the basic setting on our test engine. This ignition setting offers the best compromise between early torque and good speed behavior after peak performance. On racetracks with significantly longer straight sections, such as the club course in Magny-Cours or the new course in Mirecourt, you should take the ignition back 1 ° -2 °. When it comes to ignition timing, you have to try out what works best on your engine and what suits you best in terms of character.

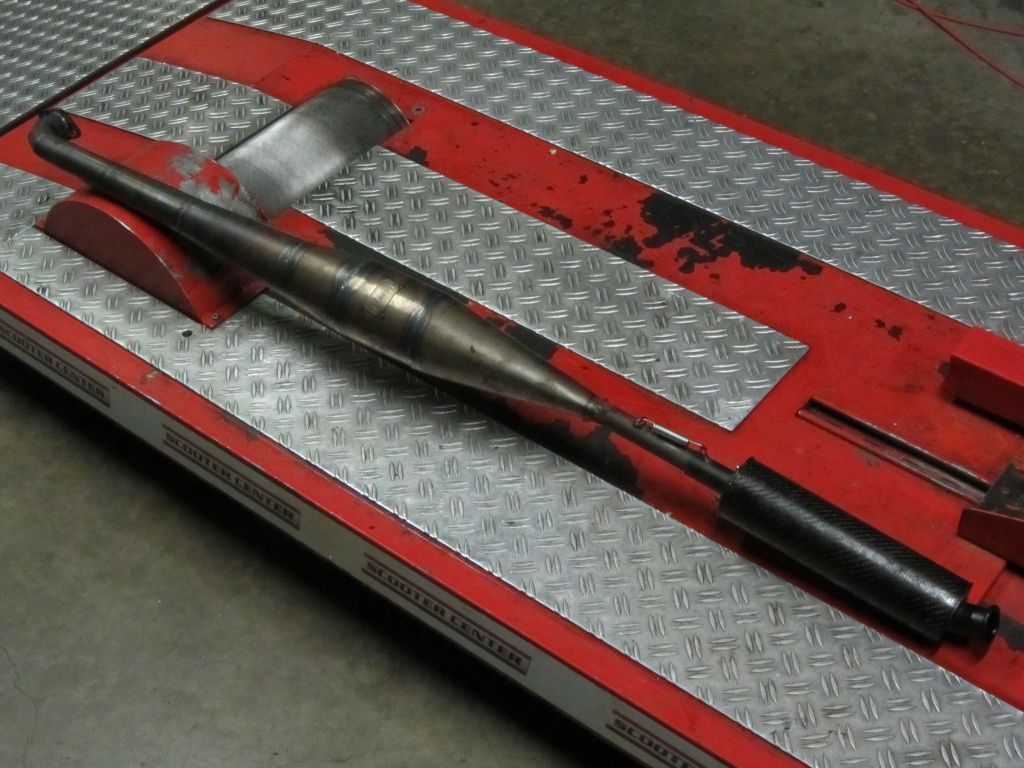

EXHAUST

The current ESC K1 exhaust is based on a prototype of the ALEX1, which works very well on class 1 cylinders with suction from the housing and enables performance well above the 25pS limit there.

The new routing makes it an ESC-K1 exhaust

with good lean angle.

ZUSAMMENFASSUNG

Permissible pinch edge 1,0 - 1,2mm

Spacer 3mm (included in delivery) to adjust the pinch edge more spacers should be used.

Spark plug:

Ignition setting (IDM based ignitions, KyTronik curve no.7)

Carburettor and jets:

Mikuni TMX 30

Idle jet 20-22,5

5EL-68 needle 2 ° -3 °

Main jet 260-280 (with PJ!)

Powerjet 85-100

Keihin PWK 28

Idle jet 38-42

Needle JJH 2 ° -3 °

Main jet 142-148